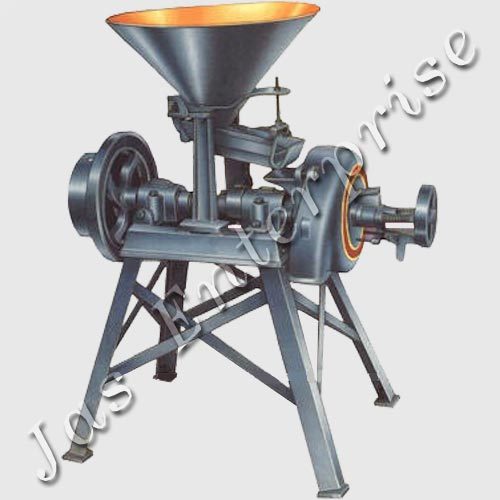

Bottom Discharge Hammer Mill

Product Details:

- Material Stainless Steel

- Type Feed Grinding Machine

- Capacity 30-35 Kg/hr

- Computerized No

- Automatic Yes

- WorkingSpeed 3500 RPM

- Power 3000 to 7000 Watt (w)

- Click to View more

Bottom Discharge Hammer Mill Price And Quantity

- 18500.00 - 125000.00 INR/Unit

- 1 Unit

Bottom Discharge Hammer Mill Product Specifications

- 3000 to 7000 Watt (w)

- 3500 RPM

- Stainless Steel

- Feed Grinding Machine

- High Performance Lower Energy Consumption Low Noise ECO Friendly High Efficiency

- No

- 110 to 415 Volt (v)

- 30-35 Kg/hr

- Yes

- Blue

Bottom Discharge Hammer Mill Trade Information

- Ahmedabad

- 1000 Unit Per Month

- Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia North America Eastern Europe Africa Western Europe Central America Middle East Asia

Product Description

With an aim to facilitate clients with best-in-class products, we have been committed to manufacture and export tough built Bottom Discharge Hammer Mill. To meet with international quality standards, this mill is engineered employing advanced technology and techniques. Post-production, this mill is stringently checked on various factors like perfect finish and optimum functionality. With the help of our trusted logistics personnel, we assure secure shipment of this Bottom Discharge Hammer Mill within the promised time frame.

Striking attributes:

- Simple installation

- Rugged construction

- Longer service life

- Seamless finish

Key Features of Bottom Discharge Hammer Mills

- Unique and Reliable Design

- The bottom discharge hammer mills are highly effective as well as nonstop continuous pulverizing process.

- Compact size

- Dust free operation

- Ideal for dry crushing

- Increased production leading to faster return on the

- All Rotating parts are balanced for reducing friction losses and noise

Operating Principle of Bottom Discharge Hammer Mills

The materials to be ground into the crushing chamber of Bottom Discharge Hammer Mills from feed hopper by gravity or through an auto feeder (optional) the beaters / blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverizes the material. The ground materials continuously discharge through screens placed at the bottom periphery of the crushing chamber and excess air filtered through a cotton balloon. Particle size is varied by using different size perforated round holes screens.

Application of Bottom Discharge Hammer Mills

- Hammer Mills are exclusively meant for the grinding of sugar, bangle grams, maize, and pulses

- Construction of Bottom Discharge Hammer Mills

- Hammer mill made from heavy duty mild steel fabricated body. Grinding chamber lined with serrated wear plates, which protects the body from wear and tear. Grinding is done by a set of swinging blades or hammers on a balanced rotor. A screen classifier forms the lower half of the grinding chamber.