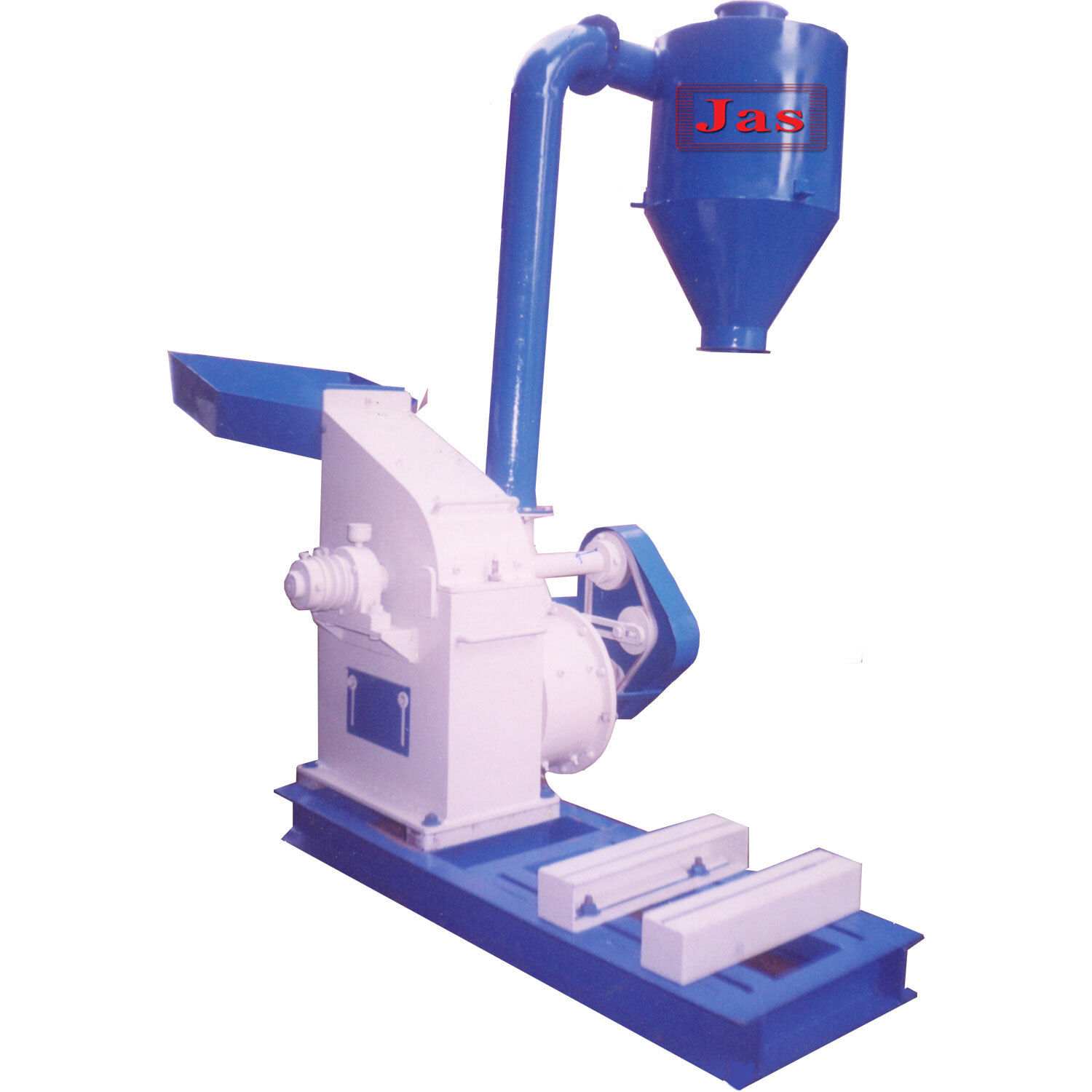

Hammer Mills

Hammer Mills Specification

- Material

- Stainless Steel

- Capacity

- 60-65 Kg/hr

- Automatic

- Yes

- WorkingSpeed

- 3500 RPM

- Power

- 3000 to 7000 Watt (w)

- Voltage

- 110 to 415 Volt (v)

- Feature

- High Performance, Low Noise, High Efficiency

- Color

- Blue

Hammer Mills Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Tripura, Manipur, Dadra and Nagar Haveli, Chandigarh, Andaman and Nicobar Islands, Nagaland, Pondicherry, Uttarakhand, , Daman and Diu, Lakshadweep, Gujarat, Haryana, South India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Uttar Pradesh, Karnataka, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, Himachal Pradesh, All India

About Hammer Mills

With the firm commitment to quality, we are involved in manufacturing and exporting a wide range of Hammer Mills. Our offered mills are manufactured using high grade raw materials and other components that are obtained from authorized vendors of market. These mills are manufactured into various grades and models that clients can avail as per their needs. Our offered mills are delivered within the stipulated period of time. Hammer Mills are offered at market leading prices.Striking characteristics:

- Easy installation

- Longer functional life

- Outstanding finish

- Safe operation

Other details:

The hammer mills is a multi-purpose mill, which handles soft, medium,hard, lumpy and irregular size materials to produce coarse to medium fine powder. The hammer mills is used for processing of spices, chilies,peeper, coriander, mix masala, ayurvedic herbal, food stuff, maize,cattle and poultry feed, tea, coffee, fish meal, etc. Feature include simple and sturdy consumption, almost dust free operation, easy and economical maintenance, consistent and dependable performance, low temperature rise for heat sensitive materials, among others. It also retains flavor, taste and color to optimum level.

Operating principle of hammer mills

The materials to be ground into the crushing chamber of hammer mills from feed hopper by gravity or through an auto feeder (optional) the beaters / blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverizes the material. The ground materials is continuously sucked by a centrifugal blower through screens placed at the bottom periphery of the crushing chamber and conveyed through a pipe into the cyclone dust collector for bagging.Excess air filtered through a cotton balloon. Particle size varied using screens with different size perforated round holes.

Product details

|

Country of Origin |

Made in India |

|

Power Source |

Electric |

|

Material |

Steel |

|

Frequency |

50 Hz |

|

Model Name/Number |

JAS-HM-48Eto |

|

Power Consumption |

2 Kwh |

|

Motor Power |

3 HP |

|

Electricity Connection |

Single Phase |

|

Usage/Application |

Maize Grinding |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Jacketed Mini Pulverizer

Price Range 32000.00 - 47000.00 INR / Unit

Minimum Order Quantity : 01 Unit

Voltage : 110 to 415 Volt (v)

Material : Cast Iron

Dalia Making Machine

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Material : Stainless Steel

Automatic : Yes

Wet Pulverizer

Price Range 8000.00 - 30000.00 INR / Unit

Minimum Order Quantity : 01 Unit

Voltage : 110 to 415 Volt (v)

Material : Stainless Steel

Automatic : No

Heavy Duty Grinding Machine

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Material : Stainless Steel

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS