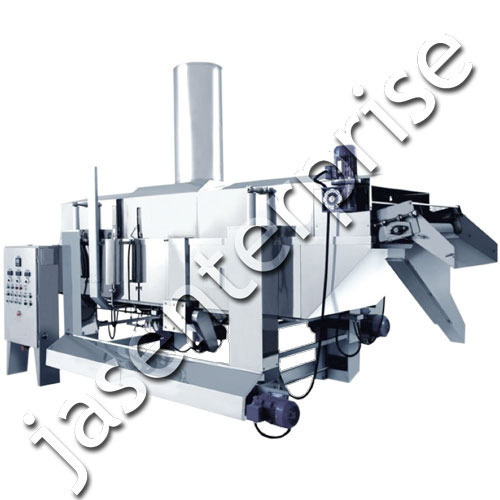

Nylon sev making machine

Price 80000 INR/ Unit

MOQ : 1 Unit

Nylon sev making machine Specification

- Material

- Stainless Steel

- Capacity

- 100 Kg/hr

- Weight (kg)

- 200 Kilograms (kg)

- Automatic

- Yes

- Dimension (L*W*H)

- 1200 x 550 X 1675 Millimeter (mm)

Nylon sev making machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

- Certifications

- 80,000 / onward

About Nylon sev making machine

Our firm establishment in this field has enabled us to manufacture and export Nylon sev making machine. These machines are manufactured in our huge infrastructure facility using cutting-edge machines and technology. The offered machines are fitted with a brass cylinder to press a uniform size of dough into hot oil. Quality components and materials are used in the manufacturing process to meet the norms and guidelines laid by the industry. We examine all our Nylon sev making machine before delivery to ensure our customers with proper functional products.Features:

- Easy to operate

- High performance

- Longer service life

- Corrosion resistant

Other details:

Nylon sev also known as plain sev, zero sev, agra sev or thin sev, this savoury is prepared using chick pea or Bengal gram flour. This adds crunchiness when added to chats like bhel puri, papdi chat, dahi puri et cetera.Combining the technology, style and comfort at a same time, we unfurl our wide range of sev extruding machines, which find their application for extruding the dough to produce very fine sev effortlessly and in minimum time. Sturdily constructed from high grade metal, these automatic machines ensure reliability, durability and zero defects. These machines are most competitively priced.

A unique brass cylinder is along with different interchangeable dies. A fine-tapper holed die is attached to the container and filled with dough, which is then pressed into hot oil where it fries into crisp nylon sev. The nylon sev making machines are supplied with three dies which may be - thin, medium & thick.

High-Efficiency Sev Production

Designed for continuous, automatic operation, this nylon sev making machine enhances productivity with a processing capacity of up to 100 kg per hour. Its stainless steel construction ensures consistent quality, ease of cleaning, and resilience within commercial environments.

Versatile Applications Across Food Industry

The nylon sev maker serves manufacturers, suppliers, and retailers. Its adaptability makes it perfect for producing various types of sev and snack variants, allowing businesses to meet customer demand with precision and speed.

FAQs of Nylon sev making machine:

Q: How does the nylon sev making machine operate automatically?

A: The machine features an automatic system that streamlines sev production, minimizing manual input. Raw ingredients are fed, processed, and extruded without constant supervision, resulting in safe, efficient, and uniform output.Q: What materials is the machine constructed from and why is this important?

A: This sev making machine is made from high-grade stainless steel, which ensures food safety, resists corrosion, and facilitates easy cleaning essential for frequent and large-scale production.Q: When is the nylon sev making machine most beneficial for businesses?

A: Businesses producing large volumes of sev or namkeen will benefit most during peak demand periods. Its high hourly capacity ensures timely order fulfillment for wholesalers, exporters, and retailers.Q: Where can this sev making machine be installed?

A: Thanks to its compact dimensions, the machine can fit in a variety of production environmentsfactories, large kitchens, and food processing units across Indiaprovided there is stable flooring and standard utilities.Q: What is the process involved in making nylon sev using this machine?

A: Operators load the prepared sev batter into the machine, which automatically extrudes and cuts it into uniform shapes, ready for frying or packaging. The automated controls optimize consistency and output.Q: How is the machines usage advantageous for food manufacturers?

A: Using this machine significantly increases efficiency, reduces labor costs, maintains product hygiene, and delivers consistent quality, making it an excellent investment for food manufacturing businesses.Q: What are the main benefits of choosing this nylon sev making machine?

A: Key benefits include high-volume production capability, reliable stainless steel build, automatic operation for labor reduction, and wide availability via distributors, manufacturers, and suppliers throughout India.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Namkeen Making Machine Category

Tilting Type Centrifuge

Price Range 25000.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 0.5 to 3 Horsepower (HP)

Automatic : No

Computerized : No

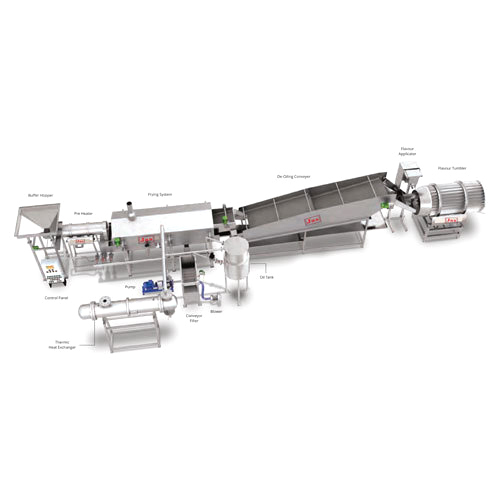

Snacks Making Line

Price 350000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 520 Horsepower (HP)

Automatic : Yes

Computerized : Yes

Chana Jor Garam Making Machine / Chana - Moong Pressing Machine

Price Range 100000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 2 Horsepower (HP)

Automatic : No

Computerized : No

Continuous Frying Systems

Price Range 1800000.00 - 10000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 8 Horsepower (HP)

Automatic : Yes

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS