Air Dryer

Price 50000 INR/ Unit

Air Dryer Specification

- Phase

- Three Phase

- Features

- Good Quality

- Computerized

- No

- Automatic

- No

- Voltage

- 440 Volt (v)

- Power

- 0.5-1 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Air Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Letter of Credit (L/C)

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Air Dryer

An air dryer is a device used to remove moisture from compressed air or gases to ensure the delivery of dry air. Moisture in compressed air systems can cause corrosion, damage to pneumatic tools, freezing in cold weather, and contamination of products or processes. Therefore, air dryers play a crucial role in maintaining the efficiency and reliability of compressed air systems.

Importance of Air Dryers

Compressed air contains moisture due to the condensation of water vapor present in the atmospheric air during the compression process. This moisture, if not removed, can cause:

-

Corrosion of pipelines and equipment

-

Malfunction or damage to pneumatic instruments and tools

-

Freezing and blockage in cold environments

-

Reduced efficiency and increased maintenance costs

-

Product contamination in sensitive industrial processes

High-Efficiency Moisture Management

Experience superior drying with our air dryer equipped to handle the rigors of industrial use. Each unit is designed to effectively remove moisture with minimal energy consumption, supporting continuity in production and reducing overall maintenance costs. Its high-efficiency performance helps maintain optimal operational conditions across various industries.

Eco-Friendly and Low-Noise Operation

Our air dryer stands out for its environmentally conscious and silent operation. The eco-friendly features ensure reduced environmental impact, while the low-noise performance contributes to a more comfortable workplace. With its compact structure, installation is simple, making it a smart choice for modern facilities seeking sustainable solutions.

FAQ's of Air Dryer:

Q: How does the air dryer operate if it is not automatic or computerized?

A: This air dryer is manually operated, which means users control and monitor the machine using standard on/off switches. Despite the lack of automation or computerized features, it delivers consistent and efficient drying, ideal for those preferring traditional, straightforward controls.Q: What are the benefits of using this air dryer in industrial applications?

A: The main advantages include high efficiency, lower energy consumption, eco-friendly operation, and reduced noise levels. Its compact structure allows for easy installation in tight spaces, making it perfect for various industrial settings where quality and sustainability are priorities.Q: When is this air dryer most suitable to use?

A: This air dryer is best employed in environments that require continuous, high-quality drying with minimal operator intervention, such as manufacturing plants, workshops, and assembly lines. Its robust design ensures reliable performance for prolonged usage.Q: Where can this air dryer be purchased or sourced in India?

A: You can acquire this air dryer through a range of channels in India, including distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers specializing in industrial equipment and machinery.Q: What is the process for installing and setting up the air dryer?

A: Installation involves connecting the unit to a suitable three-phase 440V power supply and ensuring proper placement for ventilation. Since the device is compact and not computerized, setup is straightforward, requiring only basic electrical and mechanical adjustments as outlined in the user manual.Q: How does the air dryer contribute to energy efficiency and sustainability?

A: The design prioritizes eco-friendly operation by minimizing electricity consumption while maintaining high drying efficiency. Its advanced engineering reduces waste, helping lower overall operational costs and the facility's environmental footprint.Q: What types of industries or environments benefit most from this air dryer?

A: Industries like pharmaceuticals, food processing, textiles, and general manufacturing benefit the most, as they require effective moisture control, reliable operation, and reduced environmental impact for daily operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Veg. Manchurian Making Machine

Price 45000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 220 Volt (v)

Warranty : 1 Year against manufacturing defect.

Computerized : No

Kurkure Extruder Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Warranty : One year against manufacturing defects at our site

Computerized : No

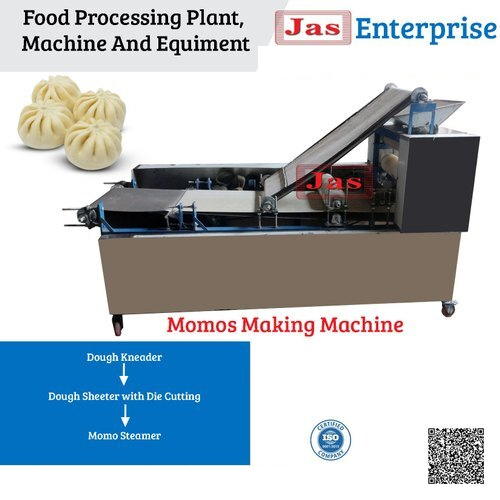

Momo Making Machine

Price 80000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Warranty : One year against manufacturing defects at our site

Computerized : No

Thepla Making Machine

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Warranty : One year against manufacturing defects at our site

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS