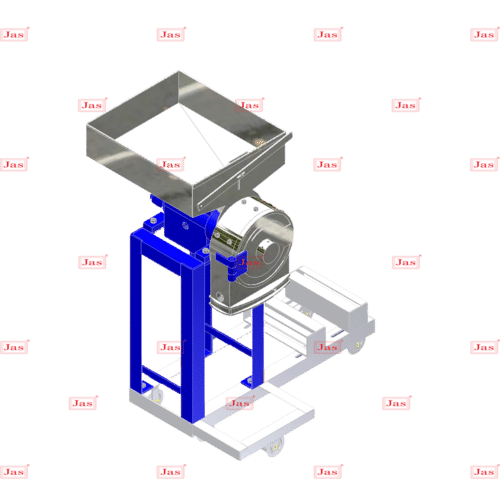

Cattle Feed Grinder

Price 15000 INR/ Unit

Cattle Feed Grinder Specification

- Model

- CFG-1000

- Rotation

- Unidirectional

- Product Type

- Feed Grinder

- General Use

- Grinding and crushing cattle feed material

- Material

- Mild Steel

- Type

- Surface Grinder Machine

- Capacity

- 800 - 1000 kg/hr

- Weight (kg)

- 1250 kg

- Computerized

- No

- Automatic

- Semi-automatic

- CNC Or Not

- No

- Control System

- Manual

- Table Size

- 1000 x 300 mm

- Table Slide Way

- Double V-Type

- Magnetic Chuck Size

- Custom Optional

- Grinding Wheel Size

- 14 inch

- Grinding Wheel Speed

- 2800 RPM

- Grinding Length

- Up to 1000 mm

- Floor Space

- 2000 x 1200 mm

- Fuel Tank Capacity

- 35 L

- Spindle Speed

- 2800 RPM

- Power

- 7.5 HP

- Voltage

- 415 V

- Dimension (L*W*H)

- 2000 x 1200 x 1500 mm

- Feature

- Heavy Duty, High Productivity

- Color

- Blue

- Dust Collection

- Integrated System

- Working Speed

- 2800 RPM

- Noise Level

- Below 85 dB

- Finish

- Powder Coated

- Motor Type

- Three Phase Induction

- Blade Material

- Alloy Steel

- Maintenance

- Low Maintenance

- Bearing Type

- Ball Bearing

- Hopper Type

- Steel Hopper with Adjustable Feed

- Mounting

- Floor Mounted

- Safety

- Overload Protection

- Application

- Cattle, Dairy, Poultry Farms

- Output Size Adjustment

- Provided

Cattle Feed Grinder Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001

About Cattle Feed Grinder

A cattle feed grinder is a machine designed to process various types of feed ingredients into a fine, uniform mixture suitable for feeding cattle. Here are the typical features and components of a cattle feed grinder:

Components:-

Hopper:

- Description: The hopper is the input section where raw feed ingredients such as grains, corn, hay, and other materials are loaded into the grinder.

- Material: Often made of metal or high-strength plastic to withstand heavy loads.

- Capacity: Varies depending on the model, typically ranging from a few hundred kilograms to several tons.

-

Grinding Mechanism:

- Description: This section includes a series of rotating blades or hammers that crush and grind the feed ingredients.

- Type: Common types include hammer mills and roller mills.

- Adjustability: Many grinders allow the user to adjust the fineness of the grind by changing the screen size or the distance between the rollers.

-

Motor:

- Description: Powers the grinding mechanism.

- Power Rating: Can range from a few horsepower (HP) for smaller units to several dozen HP for larger, industrial models.

- Type: Typically electric, but can also be powered by a tractor PTO (power take-off).

Engineered for High Productivity

Designed for continuous operation, the CFG-1000 Cattle Feed Grinder provides impressive output speeds up to 2800 RPM. Its robust 7.5 HP, three-phase induction motor ensures consistent grinding performance, making it well-suited for high-volume feed preparation on farms or commercial facilities.

Efficient and Safe Operation

Operator safety is prioritized with overload protection and a noise level kept below 85 dB. The integrated dust collection system further enhances the working environment, reducing airborne particles and contributing to both equipment longevity and operator well-being.

Flexible and Customizable Feeding

Featuring an adjustable steel hopper and customizable output size, this grinder accommodates various feed requirements. The manual control system allows users to fine-tune the grinding process for diverse applications in cattle, dairy, or poultry farm settings.

FAQs of Cattle Feed Grinder:

Q: How does the adjustable feed function work in the CFG-1000 Cattle Feed Grinder?

A: The steel hopper of the CFG-1000 is designed with an adjustable feed mechanism, allowing operators to regulate the rate and quantity of material entering the grinder. This ensures optimal grinding efficiency for different types and volumes of cattle feed materials.Q: What safety features are included in this cattle feed grinder?

A: The machine comes with overload protection, which automatically shuts off the system in case of excess load or blockages, preventing damage to the motor and reducing the risk of operator injury during operation.Q: When is this grinder most suitable for use on farms?

A: The CFG-1000 is ideal for daily grinding tasks on cattle, dairy, and poultry farms. Its robust build and high capacity make it suitable for both small-scale and commercial-scale feed processing requirements throughout the year.Q: Where should this grinder be installed for optimal performance?

A: It should be floor-mounted on a level surface within a well-ventilated feeding or processing area of the farm. The dimensions (2000 x 1200 x 1500 mm) require adequate floor space for safe operation and easy maintenance access.Q: Which process steps does the cattle feed material undergo in this machine?

A: Feed material is placed in the adjustable hopper, passes through the grinding chamber equipped with alloy steel blades, and is ground to the desired size, which can be tweaked as needed. The integrated dust collection system manages particulate matter during the process.Q: How does the integrated dust collection system benefit farm operations?

A: The dust collection system ensures a cleaner working environment by capturing airborne feed particles during grinding, thereby reducing mess, minimizing health risks, and extending the service life of the machine.Q: What are the key benefits of using the CFG-1000 for cattle feed processing?

A: Benefits include high grinding speed, a large output capacity (8001000 kg/hr), energy-efficient operation, customizable output size, low maintenance, and enhanced safety features, all contributing to greater productivity and feed quality on the farm.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Impact Pulverizer

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Capacity : 3035 Kg/hr

Automatic : Yes

Semi Automatic Micro Pulverizer

Price 11500 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : No

Chilli Grinding Machine

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Voltage : 110 to 415 Volt (v)

Capacity : 3035 Kg/hr

Automatic : Yes

Red Chilli Pounding Machine

Price 41000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 820 Kg/hr

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS