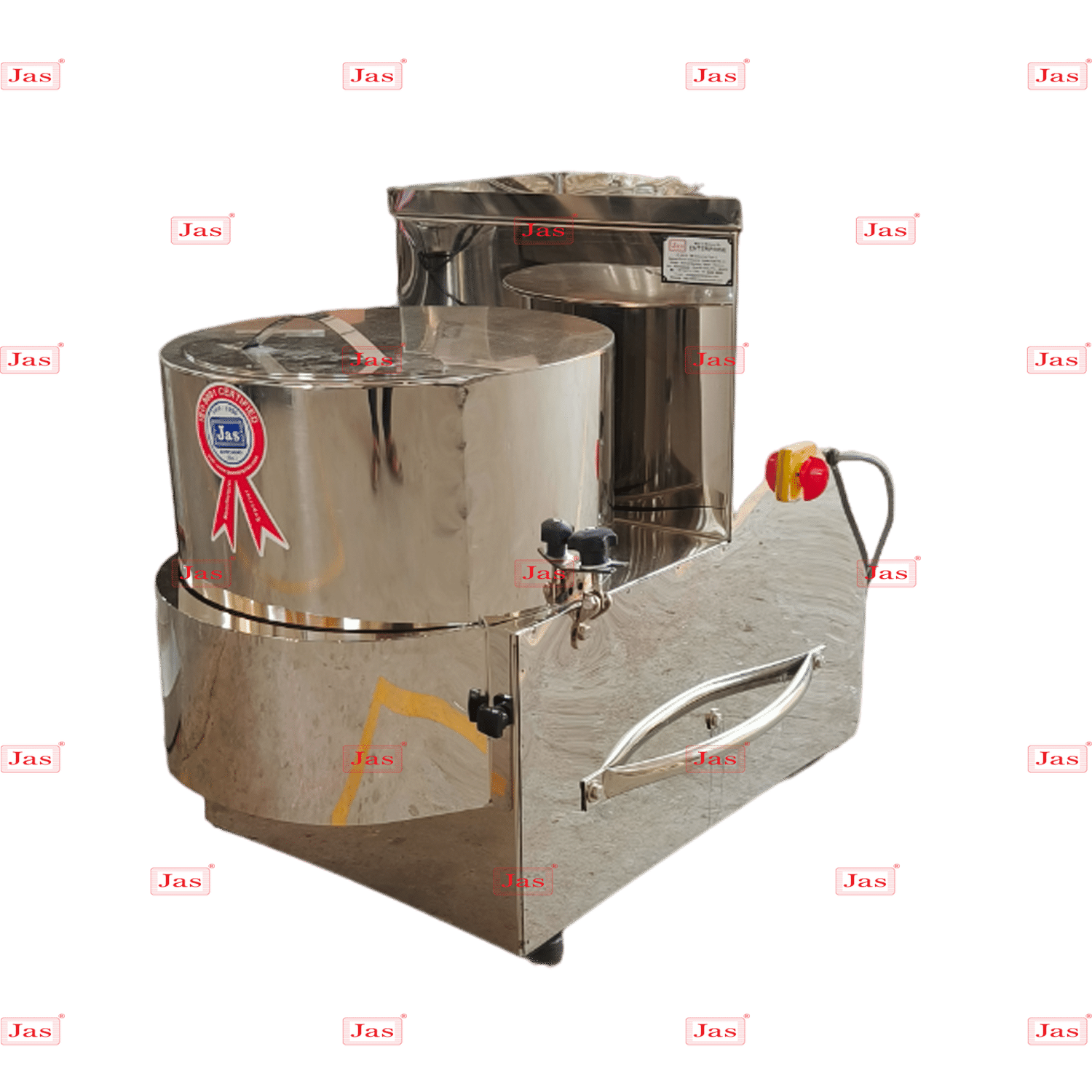

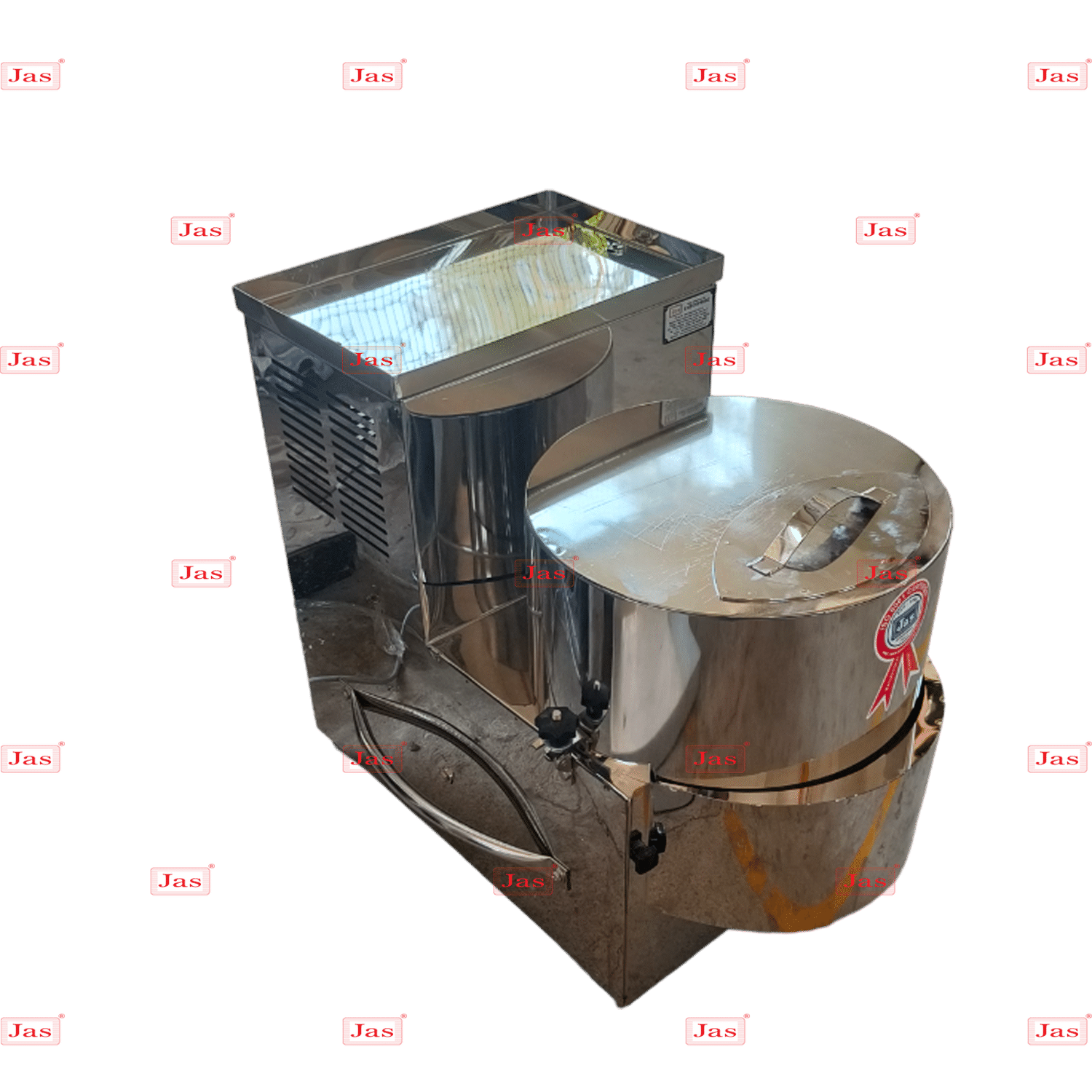

Commercial Slicer

Price 5000 INR/ Unit

Commercial Slicer Specification

- Capacity

- 125-150 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Commercial Slicer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Commercial Slicer

Types of Commercial Slicers:

-

Manual Slicers:

- Operated by a hand crank or lever.

- Offers more control over thickness and slicing speed.

- Requires more physical effort but tends to be less expensive.

-

Automatic Slicers:

- Powered by an electric motor.

- Provides consistent slices with less manual effort.

- Ideal for high-volume operations.

Features to Look For:

-

Blade Size:

- Blades can range from 7 to 14 inches in diameter.

- Larger blades are generally used for slicing larger or thicker products.

-

Thickness Adjustment:

- Look for precise control to adjust the thickness of slices.

- This feature is crucial for ensuring consistency in food preparation.

-

Build Quality:

- Typically made from stainless steel or aluminum for durability and ease of cleaning.

- Some models feature removable parts for thorough sanitation.

-

Safety Features:

- Safety guards and blade covers to protect users from accidental cuts.

- Non-slip feet or suction cups to keep the slicer stable during use.

-

Ease of Cleaning:

- Removable parts and smooth surfaces make cleaning easier and more effective.

Maintenance Tips:

-

Regular Cleaning:

- Clean the slicer after each use to prevent the buildup of food residues.

- Disassemble parts as needed for a thorough cleaning.

-

Blade Sharpening:

- Keep the blade sharp for efficient slicing and to reduce strain on the motor.

- Use a specialized sharpener or have it professionally sharpened.

-

Inspect for Wear and Tear:

- Regularly check for any signs of damage or wear, especially in high-use environments.

-

Lubrication:

- Apply food-safe lubricants to moving parts as recommended by the manufacturer.

Eco-Friendly, High-Efficiency Design

This commercial slicer is built to reduce environmental impact through lower energy consumption and minimized noise output. Its advanced engineering maintains top performance, contributing to a sustainable and efficient workflow in busy kitchens and production lines.

Versatile Power Compatibility and Automation

Supporting 230/440 Volt operations, the slicer fits diverse commercial power settings across India. Full automation not only enhances productivity and consistency but also ensures user-friendly operation, reducing manual labor and operational errors.

FAQs of Commercial Slicer:

Q: How does the commercial slicer benefit my business operations?

A: The slicer offers a fast processing capacity of 125-150 kg/hr, helping you handle large food quantities efficiently. Its automatic function minimizes operator intervention, while eco-friendly and energy-saving features reduce utility costs, making your operations more sustainable and cost-effective.Q: What makes this slicer eco-friendly and energy-efficient?

A: This machine is engineered for lower energy consumption without compromising slicing performance. Its design minimizes noise and power use, supporting environmentally conscious practices in your facility while maintaining high output.Q: When should I consider purchasing this slicer for my establishment?

A: If your business requires rapid and consistent food slicingtypically in restaurants, hotels, food processing units, or catering companiesthis slicer is an ideal investment once your throughput regularly exceeds manual or smaller-scale equipment limits.Q: Where can I acquire this commercial slicer in India?

A: You can purchase this slicer through a wide network of distributors, exporters, manufacturers, retailers, traders, wholesalers, and suppliers throughout India, ensuring convenient access and prompt after-sales support.Q: What is the installation process for the slicer, and is it suitable for all commercial setups?

A: Installation is straightforward thanks to its compact structure. The slicer supports both 230 and 440 Volt electrical systems, making it compatible with most commercial kitchens or processing lines across India.Q: How does the automatic operation improve usage and efficiency?

A: Automatic operation streamlines the slicing process, allowing consistent results and higher throughput while reducing labor efforts. This maximizes efficiency and productivity, especially during peak operating hours.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Popcorn Machine

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Voltage : 110440 Volt (v)

Capacity : 1 to 6 Kg/Batch Kg/day

Computerized : No

Pasta Extruder Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Capacity : 125 kg/Hr Kg/hr

Computerized : No

Circular Vibratory Screeners and Separators

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Capacity : 70 Kg/hr

Computerized : No

Carrot Juicer Machine

Price 6800 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free