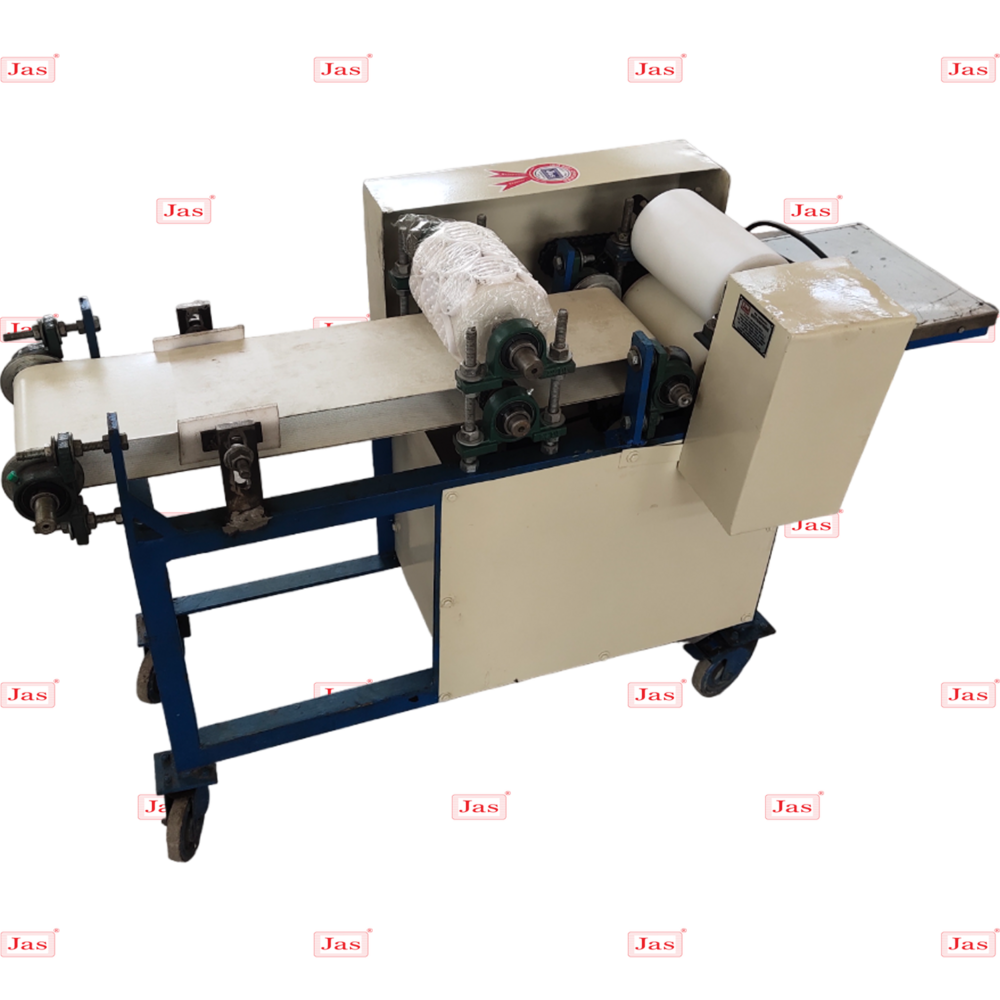

Continuous Papad Dryer

Price 5000 INR/ Unit

MOQ : 1 Unit

Continuous Papad Dryer Specification

- Material

- Stainless Steel

- Type

- Snacks Extruder

- Capacity

- 15 to 16 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Power

- 1500 Watt (w)

- Dimension (L*W*H)

- 18 X 2 X 7 Foot (ft)

Continuous Papad Dryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Continuous Papad Dryer

Ours is a coveted firm involved in manufacturing and exporting robustly built Continuous Papad Dryer. This dryer is manufactured using quality assured raw materials and other components that are procured from dependable sources of the market. Our offered dryer is available in different models and specifications as demanded by the clients. We thoroughly check this dryer with the help of our highly skilled quality experts to rule out the possibility of any flaws. This Continuous Papad Dryer is safely transported to the clients with the help of our reliable logistics personnel.Striking attributes:

- Seamless finish

- Longer service life

- Rugged construction

- Optimum functionality

Continuous Papad Dryer

An electric or LPG or CNG or Diesel drier would be use to dry the Papad. The Dryer casing would be reinforcing by means of M. S. sections to make it sturdy. Digital temperature meters, ampere meters would be providing at control panel in the oven. Above 15 to 16 Kg/hour pant, we will supply laminator type along with the sheeter and extruder process will be omits. Drier can also supply with diesel fired or liquefied petroleum gas instead of electric fired system for reducing daring cost.Highly Efficient Papad Drying Solution

Our Continuous Papad Dryer offers a remarkable capacity of 15 to 16 kg per hour, making it ideal for businesses seeking to improve output and consistency. The automatic system reduces manual intervention, while the stainless steel body maximizes hygiene and longevity.

Durable and Safe Construction

Crafted from stainless steel, this dryer is both corrosion-resistant and easy to maintain. The 1500-watt power system provides reliable, even heating, ensuring superior drying performance without compromising safety.

Versatile for Multiple Business Types

This machine serves manufacturers, wholesalers, retailers, and exporters effortlessly. Its straightforward operation allows integration into existing production lines and is suitable for varied scales of papad production, from local retail to large-scale export.

FAQs of Continuous Papad Dryer:

Q: How does the Continuous Papad Dryer enhance the papad drying process?

A: The dryer provides a continuous and uniform drying environment, using a 1500-watt heating system to maintain optimal temperature. This automation minimizes manual handling, ensures consistent quality, and significantly increases production output.Q: What are the key benefits of using a stainless steel automatic papad dryer?

A: The stainless steel construction guarantees durability, corrosion resistance, and food safety. Its automatic operation reduces labor costs, maintains hygiene, and delivers uniformly dried papads, enhancing product appeal and shelf life.Q: When should I use a continuous papad dryer in my production process?

A: The dryer is best used after forming and shaping the papads. Introducing it immediately after papad extrusion ensures efficient moisture removal, enabling rapid throughput and reducing bottlenecks in production lines.Q: Where can this continuous papad dryer be installed?

A: The dryer is suitable for installation in food processing units, snack manufacturing plants, and commercial kitchens. Its compact footprint of 18 x 2 x 7 feet allows flexibility in placement, accommodating diverse workspace configurations.Q: What is the process involved in operating this papad dryer?

A: Simply load the freshly shaped papads onto the conveyor. The automatic system carries them through the drying chamber, where consistent heat removes moisture. Dried papads exit ready for packing or further processing.Q: How can businesses benefit from this dryer model in India?

A: As a reliable solution distributed, exported, manufactured, and supplied in India, it supports diverse business needsstreamlining workflows, improving output quality, and boosting potential for local and export sales.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Papad Making Machines Category

Continuous Papad Dryers

Price Range 140000.00 - 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 1 TO 10 Horsepower (HP)

Capacity : 50 to 500 Kg/hr

Voltage : 110440 Volt (v)

Appalam Machines

Price Range 80000.00 - 280000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 1 TO 10 Horsepower (HP)

Capacity : 5 to 500 Kg/hr

Voltage : 110440 Volt (v)

Semi Automatic Cholafali Machine

Price Range 140000.00 - 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 1 TO 10 Horsepower (HP)

Capacity : 15 TO 500 Kg/hr

Voltage : 110440 Volt (v)

Papad Cutting Machine

Price 40000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Power : 0.51.5 Horsepower (HP)

Capacity : 20018000 Pcs/hr

Voltage : 230 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS