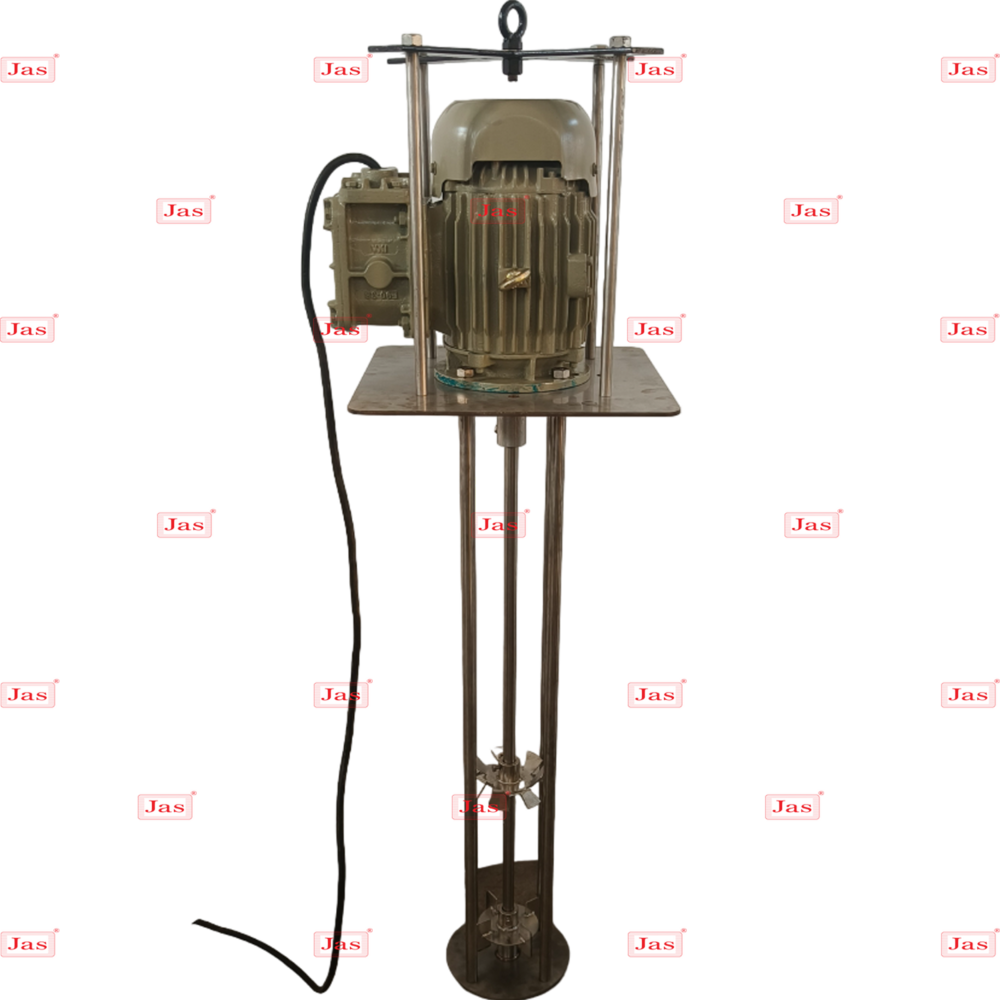

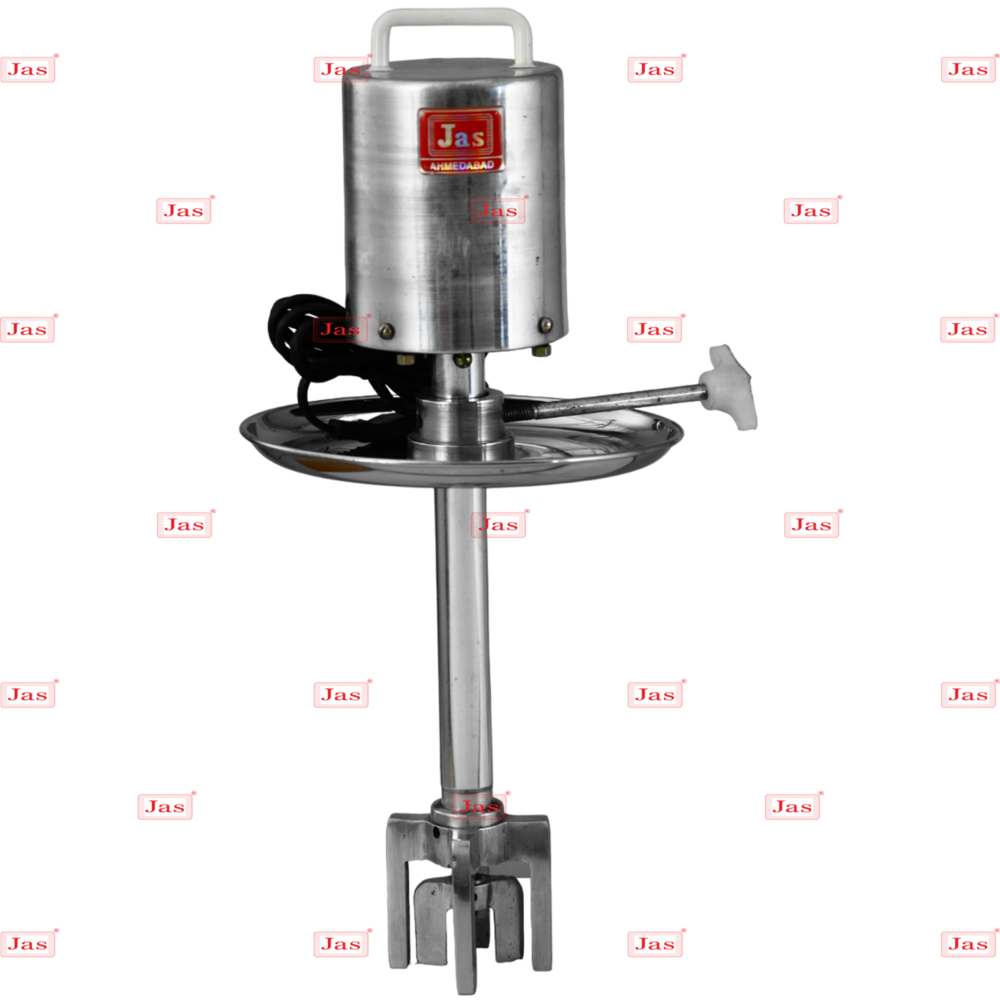

Curd Churner Machine

Price 1590 INR/ Unit

Curd Churner Machine Specification

- Frequency

- 50-60 Hertz (HZ)

- Automation Grade

- Semi Automatic

- Phase

- Single Phase

- Capacity

- 50-200 liter Ltr

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Voltage

- 230 Volt (v)

- Power

- 0.5-1 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Curd Churner Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Curd Churner Machine

The Curd Churner Machine is an advanced, mechanized device designed to simplify and enhance the traditional process of churning curd to extract butter. Traditionally, butter is separated from curd by manual churning, which is labor-intensive, time-consuming, and inconsistent in quality. This machine automates the entire process, improving efficiency, hygiene, and output quality.

Constructed primarily from high-grade stainless steel or food-grade materials, the machine ensures durability, corrosion resistance, and compliance with hygiene standards required for food processing. Its robust design is built to withstand continuous operation in dairy farms, milk processing units, and commercial dairy industries.

High-Efficiency Curd Churning for Modern Dairies

Engineered for productivity and sustainability, our curd churner machine offers a seamless churning process. It combines a semi-automatic operation with manual control, giving users direct oversight to produce consistent curd quality each batch. Its eco-friendly design ensures it operates with reduced noise and energy consumption, making it a practical choice for businesses seeking to minimize their environmental impact while maximizing output.

Versatile Capacity for Growing Businesses

Whether you operate a small dairy or a medium-scale processing unit, the 50-200 liter capacity range accommodates varied production needs. The durable and compact construction ensures installation is convenient, even where space is limited. This product is ideal for distributors, retailers, and manufacturers aiming to broaden their offerings while keeping operational costs low.

FAQ's of Curd Churner Machine:

Q: How do I operate the Curd Churner Machine?

A: The curd churner machine functions with manual controls, making it simple to start and stop the churning process. Load the required amount of curd mixture (between 50 to 200 liters), set your desired duration, and manage the process using the control switches. Detailed instructions are provided for safe and optimal operation.Q: What type of power supply is required for this machine?

A: This curd churner operates on a single-phase power supply, requiring 230 volts and a frequency of 50-60 Hertz. It is designed to consume lower energy (0.5-1 HP), making it suitable for most standard electric setups found in Indian dairies.Q: When should I use this churner in the curd production process?

A: Use the machine after the curd fermentation step, once the milk has set. Transfer the curd into the machine and start the churning process. This ensures even consistency and efficient separation of whey.Q: Where can the curd churner machine be installed?

A: The compact structure allows for easy installation in small dairy plants, medium-sized processing units, and retail outlets. Its low noise and efficient use of space make it suitable for urban and rural locations alike.Q: What is the process of cleaning and maintaining this machine?

A: After each use, clean the inner surfaces with water and a food-safe detergent. Regular maintenance includes checking the manual controls, lubricating moving parts, and ensuring the power supply is stable. Detailed maintenance guidelines are provided with the machine.Q: How does this machine benefit my dairy business?

A: The curd churner delivers high efficiency, uniform quality, lower operational costs, and eco-friendly performance. Its energy-saving design and user-friendly controls help boost productivity without compromising on product consistency, making it a valuable asset for any dairy operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Stainless Steel Grinder

Price 9000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Computerized : No

Warranty : One year against manufacturing defects at our site

Commercial Atta Chakki Machine

Price 28000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Computerized : No

Warranty : One year against manufacturing defects at our site

Shakkar Para Nimki Making Machine

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Automatic : Yes

Computerized : Yes

Warranty : 1 Year Against Manufacturing Defect At Our Site

Rotary Sieve

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Computerized : No

Warranty : One year against manufacturing defects at our site

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS