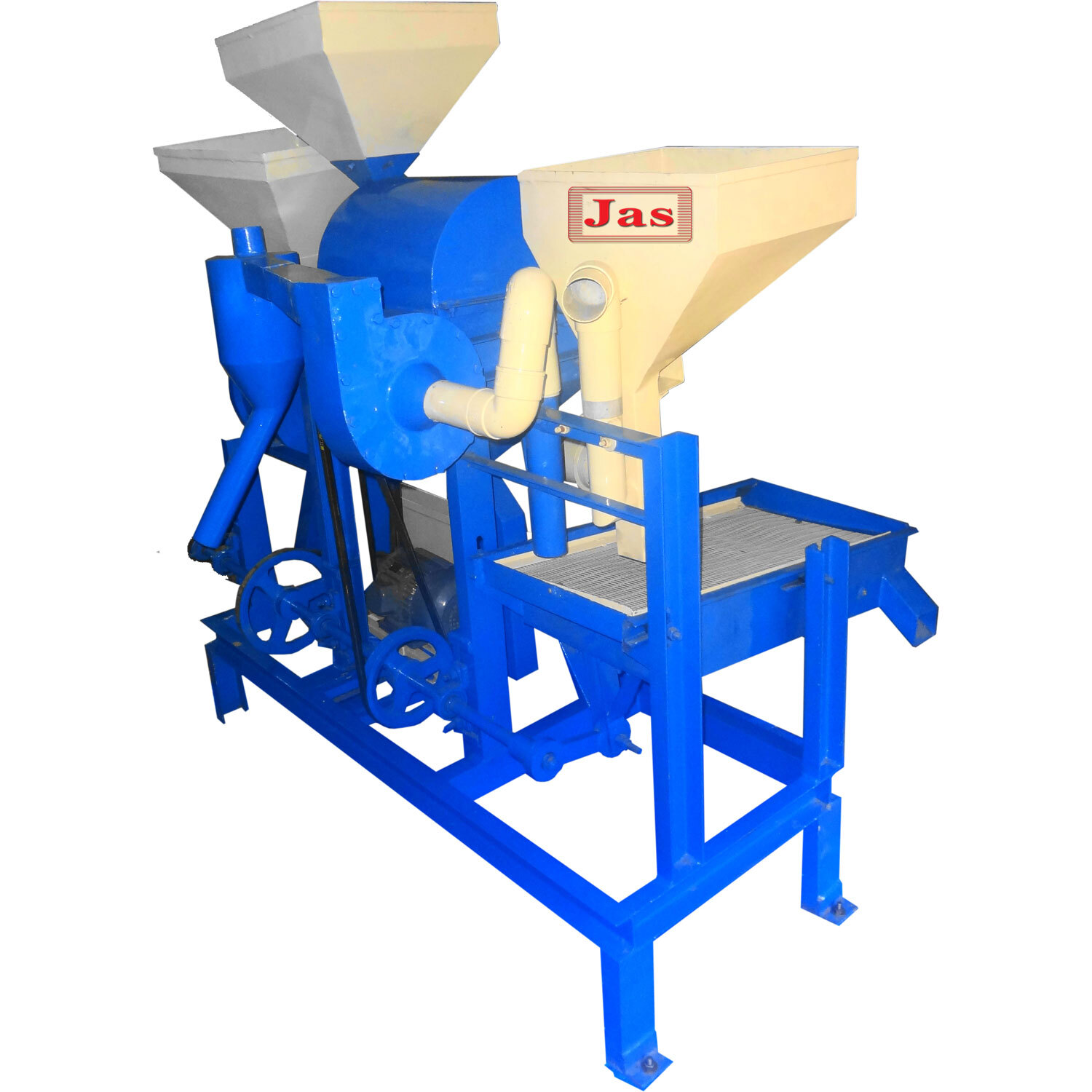

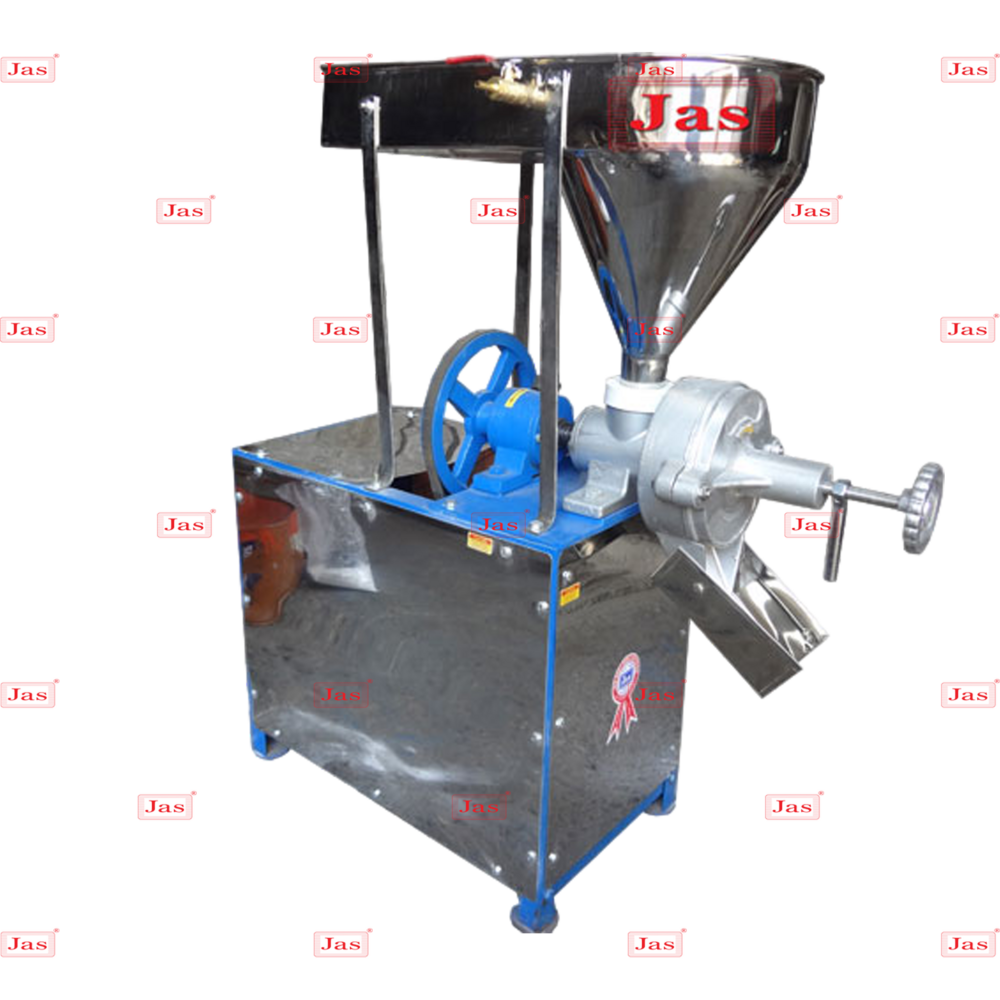

Flour Mill Machinery and Accessories

MOQ : 1 Unit

Flour Mill Machinery and Accessories Specification

- Material

- Stainless Steel

- Capacity

- 30-35 Kg/hr

- Weight (kg)

- 60 Kilograms (kg)

- Automatic

- Yes

- Power

- 1500 Watt (w)

- Voltage

- 110 Volt (v)

- Color

- Blue

Flour Mill Machinery and Accessories Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- Months

About Flour Mill Machinery and Accessories

Our organization is established among the leading manufacturers and exporters of quality assured Flour Mill Machinery. This machinery is manufactured using quality assured stainless steel and other components that are sourced from certified vendors of the market. Our offered machinery is manufactured into models and specifications as per the choices of clients. This machinery is extensively used for flour grinding purposes. Clients can avail this Flour Mill Machinery at pocket-friendly prices.This machinery is highly appreciated for:

- High tensile strength

- Less maintenance

- Long service life

- Robust construction

Superior Performance with Stainless Steel Reliability

Crafted entirely from high-quality stainless steel, this flour mill machinery resists corrosion and delivers consistent performance even in demanding environments. With an automatic operation and user-friendly interface, it significantly simplifies the grain milling process while ensuring minimal maintenance and long-lasting service.

Efficient Capacity for Commercial Use

Boasting a processing range of 30-35 kg per hour, this flour mill is tailored to meet the needs of businesses seeking to maximize productivity without sacrificing quality. Its 1500-watt power consumption supports seamless, continuous milling, making it ideal for commercial kitchens, retail stores, and bulk suppliers throughout India.

FAQs of Flour Mill Machinery and Accessories:

Q: How does the automatic flour mill machinery enhance the milling process?

A: The automatic function of the flour mill streamlines the entire milling process. Operators simply need to load the grain, and the machinery handles the restmaintaining optimal settings for efficiency, reducing manual intervention, and minimizing the risk of operational errors.Q: What are the primary benefits of using stainless steel flour mill machinery?

A: Stainless steel construction ensures the equipments durability and resistance to rust, prolongs its lifespan, and preserves the hygiene of processed flour. This makes it highly suitable for food processing environments where cleanliness and reliability are paramount.Q: When is the best time to consider upgrading to an automatic stainless steel flour mill?

A: Businesses experiencing increasing flour demand or seeking greater consistency and hygiene in their milling process should consider upgrading to an automatic stainless steel flour mill. Enhanced automation ensures higher yield and consistent flour quality with every batch.Q: Where can this flour mill machinery be sourced in India?

A: This flour mill is distributed, exported, and retailed by trusted suppliers, traders, and wholesalers across India. Whether you are a manufacturer or retailer, you can easily find authorized distributors offering nationwide delivery and after-sales support.Q: What is the process for operating this automatic flour mill machinery?

A: After connecting the machine to a 110V power supply and adding the desired grain, simply select the appropriate settings. The mill will automatically process the grains, delivering finely-milled flour at a rate of 30-35 kg per hour, with little need for user supervision.Q: How can businesses benefit from the 30-35 kg/hr production capacity of this machine?

A: With a processing capacity of 30-35 kg per hour, businesses can meet high demands efficiently, reducing waiting times and improving overall productivity. This makes the machinery especially advantageous for wholesalers, large-scale retailers, and commercial kitchens.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Grinding, crushing and Pulverizing Machine Category

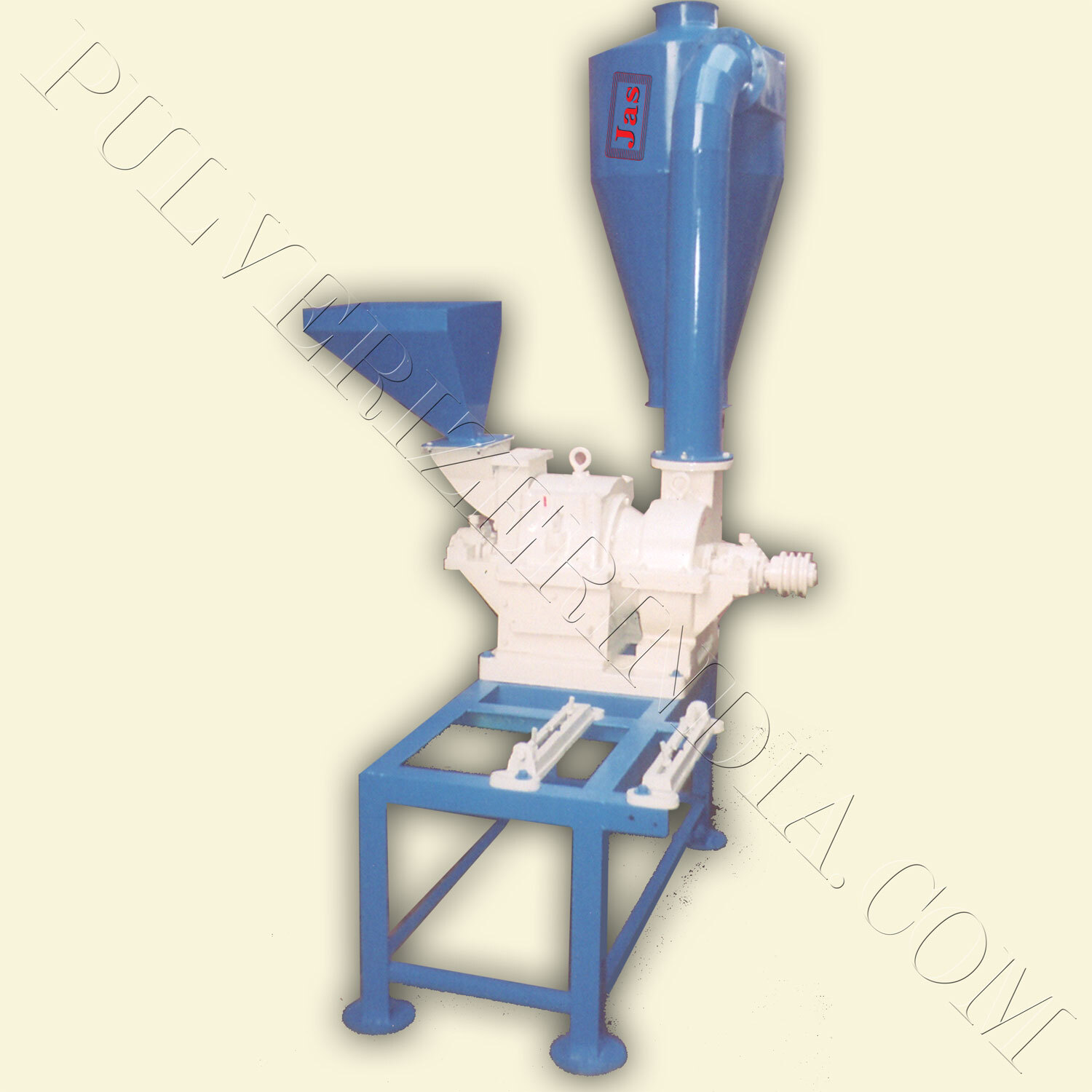

Wet Pulverizer

Minimum Order Quantity : 01 Unit

Capacity : 20 to 500 Kg/hr

Voltage : 110 to 415 Volt (v)

Automatic : No

Power : 745 7457 Watt (w)

Pulses and Grains Grinding Pulverizer

Price 30000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 8 to 80 Kg/hr

Voltage : 110 to 415 Volt (v)

Automatic : Yes

Power : 1 to 10 Horsepower (HP)

Commercial Jadibuti Grinder

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 30160 Kg/hr

Voltage : 230/440 Volt (v)

Automatic : No

Power : 210 Horsepower (HP)

Rice Powder Grinding Machine

Price 24000 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : 30100 Kg/hr

Voltage : 230/440 Volt (v)

Power : 0.52 Horsepower (HP)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free