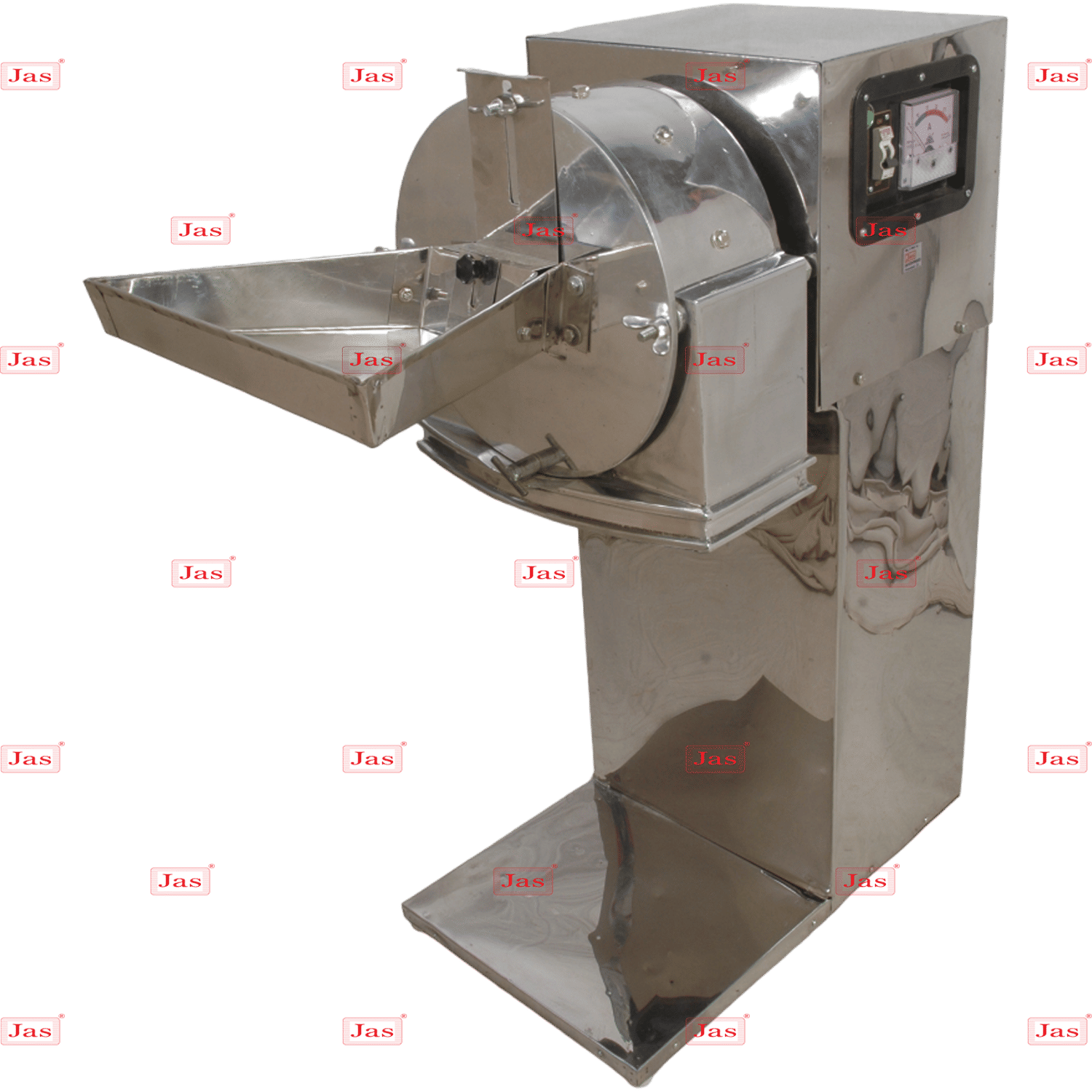

Food Grinder

Price 56000 INR/ Unit

Food Grinder Specification

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 30-160 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

- Color

- Other

- Warranty

- 1 Year

Food Grinder Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union, Cash Against Delivery (CAD)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Food Grinder

-

Manual vs. Electric:

- Manual grinders require you to turn a crank to push food through the grinder. Theyre usually more affordable and dont require electricity.

- Electric grinders are faster and more convenient, especially if youre processing large quantities.

-

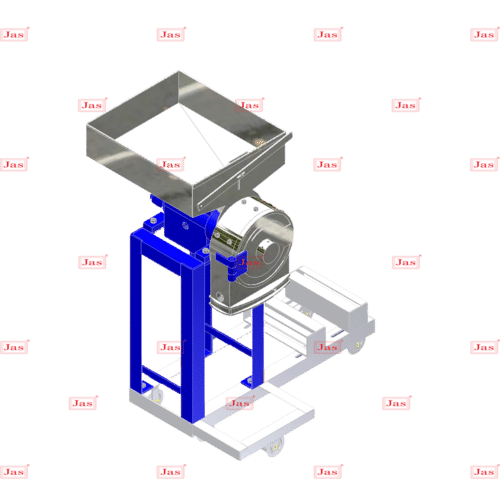

Parts of a Food Grinder:

- Hopper: The part where you place the food to be ground.

- Auger: A spiral component that pushes food towards the grinding plate.

- Grinding Plate: A disc with holes through which the food is pushed to be minced.

- Knife: A sharp blade that helps cut the food into smaller pieces before its pushed through the plate.

-

Common Uses:

- Vegetables: Make vegetable patties or sauces.

- Nuts and Seeds: Grind for baking or making nut butters.

- Grains: Grind grains into flour.

Robust Construction & High Efficiency

Built from stainless steel, this industrial food grinder guarantees durability and a consistent performance rate. Its automatic operation allows for high efficiency while maintaining lower energy consumption and minimal noise, making it an excellent choice for busy food processing environments.

Eco-Friendly & User-Oriented Design

The food grinder emphasizes sustainability through energy-saving technology and quiet operation. The non-computerized system simplifies usage for operators, while the broad capacity range caters to various industrial requirements, serving businesses of all scales.

FAQs of Food Grinder:

Q: How does the food grinder ensure high performance and efficiency in industrial settings?

A: The food grinder features an automatic grinding mechanism and a quality stainless steel build, supporting capacities between 30 and 160 kg/hr. Its motor operates on 230/440 volts, enabling optimal performance while maintaining energy efficiency and low noise during continuous industrial operation.Q: What is the warranty coverage for this food grinder?

A: The grinder comes with a 1-year warranty that covers manufacturing defects and ensures peace of mind for industrial users. Support and service are provided by distributors, exporters, and suppliers throughout India.Q: When should I use this industrial food grinder for maximum benefit?

A: This food grinder is best used in situations demanding the processing of large food quantitiessuch as commercial kitchens, food factories, and catering services. Its high-efficiency and eco-friendly design provide maximum benefit during prolonged and repeated use.Q: Where can I purchase this food grinder in India?

A: You can acquire this food grinder from a network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers located throughout India, ensuring nationwide availability.Q: What is the process for operating the automatic food grinder?

A: Operating the grinder involves connecting it to a 230/440 Volt power supply, loading food items into the hopper, and activating the automatic grinding function. Its user-friendly, non-computerized system makes operation straightforward for industrial staff.Q: How does the food grinder support eco-friendly operations?

A: The grinder is engineered for lower energy consumption and minimal noise production, significantly reducing its environmental impact. This eco-friendly feature supports sustainable practices in modern food processing industries.Q: What advantages does the stainless steel material provide?

A: Stainless steel ensures a robust and hygienic surface, perfect for food processing environments. Its resistant to corrosion and easy to clean, promoting product longevity and maintaining food safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Semi Automatic Micro Pulverizer

Price 11500 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Automatic : No

Commercial Jadibuti Grinder

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 30160 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Automatic : No

Commercial Jadibuti Grinder

Price 56000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 30160 Kg/hr

Feature : High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Double Stage Pulverizer

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Capacity : 3035 Kg/hr

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS