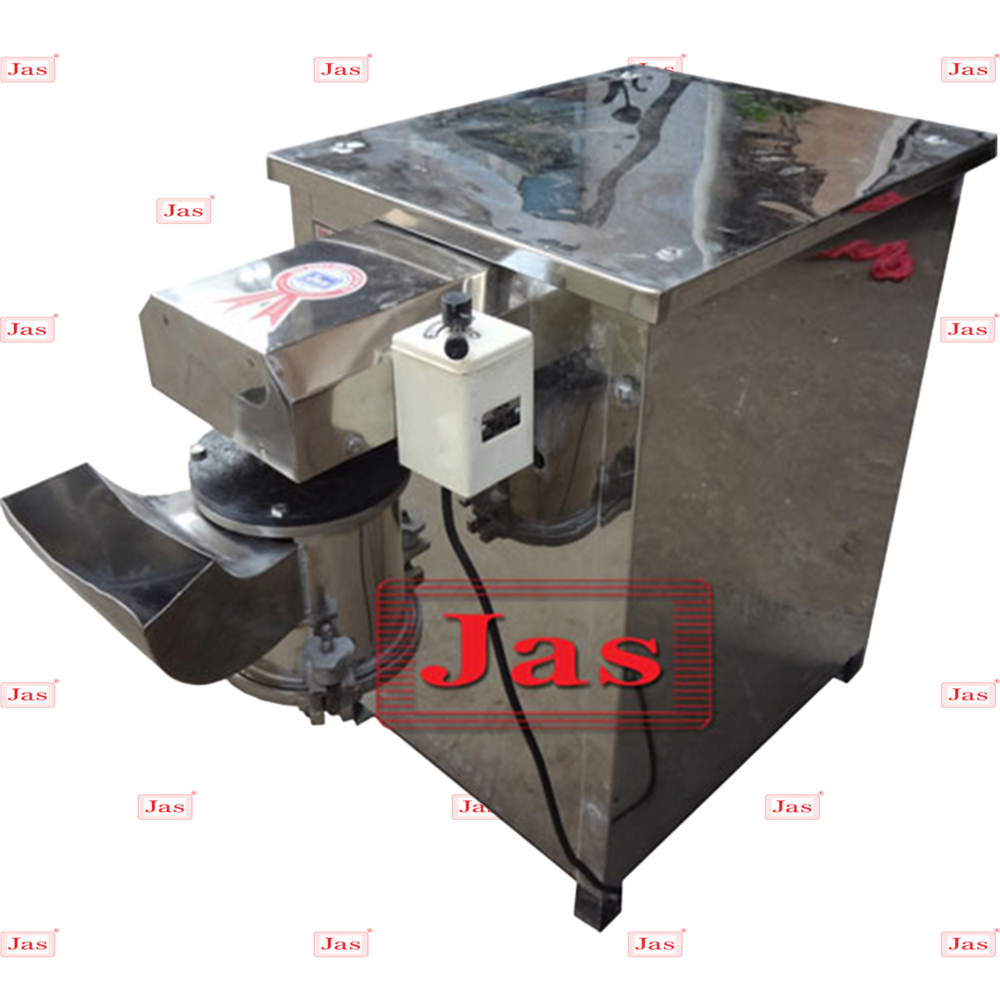

Fruit Processing Machinery

Price 390000 INR/ Unit

Fruit Processing Machinery Specification

- Phase

- Three Phase

- Speed Mode

- Variable

- Heating Method

- Electric / Steam (optional)

- Operating Temperature

- 0-50C

- Noise Level

- Low (< 70 dB)

- Machine Type

- Automatic Fruit Processing Line

- Function Type

- Multi-Function

- Power Source

- Electric

- Feeding System

- Belt Conveyor

- Automation Grade

- Automatic

- Frequency

- 50 Hz

- Features

- High Efficiency, Hygienic Design

- Product Type

- Fruit Processing Machinery

- General Use

- Fruit Washing, Sorting, Pulping, Juice Extraction

- Material

- Stainless Steel

- Type

- Washer, Sorter, Grinder, Pulper, Conveyor System

- Capacity

- 500-5000 Kg/hr

- Weight (kg)

- 1500 kg

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Floor Mounted

- Voltage

- 380-440 V

- Power

- 12 kW

- Dimension (L*W*H)

- 3000 x 1200 x 1500 mm

- Raw Material

- Stainless Steel

- Feature

- Corrosion Resistance, Easy to Operate

- Color

- Silver

- Maintenance

- Easy to Dismantle and Clean

- Fruit Compatibility

- Suitable for Mango, Apple, Orange, Banana, Pineapple

- Safety

- Advanced Safety Interlocks

- Ambient Humidity

- < 95% Rh

- User Interface

- Digital Panel Display

- Production Cycle Time

- 30 min

- Inlet Size

- 300 mm

- Package Inclusion

- User Manual, Spare Parts Kit

- Warranty Extension

- Available on Request

- Conveyor Belt Material

- Food Grade PVC

- Blade Material

- High Carbon Stainless Steel

- Application Area

- Fruit Processing Factories, Food Industry

- Outlet Size

- 400 mm

- Output Quality

- Hygienic, Ready for Packaging

- Transportability

- Forklift Compatible

- Safety Grade

- IP 54

- Water Consumption

- 120 L/hr

- Cleaning System

- Self-Cleaning

- Lubrication Type

- Automatic

Fruit Processing Machinery Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Certifications

- ISO 9001

About Fruit Processing Machinery

Jas Enterprise is renowned for its expertise in manufacturing and exporting high-quality fruit processing machinery. Our advanced and efficient machines are designed to meet the diverse needs of the fruit processing industry. Our product range includes:

-

Centrifugal Juicer:

- Description: The Centrifugal Juicer operates at high speeds to extract juice from fruits by spinning them, separating the juice from the pulp through centrifugal force.

- Features: High extraction efficiency, easy to clean, durable construction, and suitable for a variety of fruits.

-

Mastication Juicer:

- Description: The Mastication Juicer employs a grinding mechanism that chews and crushes the fruit, ensuring maximum juice extraction with minimal nutrient loss.

- Features: Slow juicing process to preserve nutrients, versatile usage for fruits and vegetables, quiet operation, and robust design.

-

Pulper Machine:

- Description: The Pulper Machine efficiently separates the pulp from the juice, making it ideal for processing large quantities of fruit into purees, pastes, or juices.

- Features: High throughput capacity, easy maintenance, stainless steel construction, and adjustable settings for different fruits.

-

Fruit Mill:

- Description: The Fruit Mill is designed for grinding and crushing fruits into smaller pieces or a paste, making it essential for pre-processing before further treatment or juice extraction.

- Features: Powerful motor, adjustable grinding settings, durable build, and easy-to-clean components.

-

Fruit Dehydration Machine:

- Description: The Fruit Dehydration Machine removes moisture from fruits, extending their shelf life while preserving their nutritional value and flavor.

- Features: Uniform drying, energy-efficient operation, large capacity, and user-friendly controls.

Jas Enterprise is committed to providing innovative and reliable fruit processing solutions to enhance productivity and quality in the fruit processing industry. Our machines are engineered for performance, durability, and ease of use, ensuring satisfaction and efficiency in every operation.

Contact Information:

For more information or to place an order, contact us at:

- Phone: +91 94260 88680

Unmatched Hygiene & Ready-for-Packaging Output

With a self-cleaning system, food-grade PVC conveyors, and stainless steel construction, this machinery delivers hygienic and contaminant-free fruit products ready for packaging. The design greatly reduces manual handling, minimizes contamination risk, and adheres to high sanitation standards required by the food industry.

Multi-Fruit Compatibility & Flexible Processing

The machine processes a wide variety of fruitsmango, apple, orange, banana, and pineapplemaking it versatile for changing market or seasonal demands. Its variable speed mode and multi-function capabilities allow seamless alternating between different fruit batches, maximizing productivity and adaptability.

Safety & Maintenance Simplified

Equipped with advanced safety interlocks and an IP54 safety grade, operators are well-protected. The system is easy to dismantle and clean, features automatic lubrication, and includes a spare parts kit. These features reduce downtime and simplify regular maintenance routines for uninterrupted operation.

FAQs of Fruit Processing Machinery:

Q: How does the fruit processing machinery ensure hygienic operation during processing?

A: This equipment employs a self-cleaning system, high-carbon stainless steel blades, and food-grade PVC conveyor belts to maintain optimal sanitation. Its robust stainless steel build resists corrosion and supports strict hygiene required for ready-to-package fruit products.Q: What types of fruits can be processed with this machine, and how flexible is it for different applications?

A: The machinery is compatible with mango, apple, orange, banana, and pineapple, enabling users to process multiple fruits efficiently. Its multi-function design and variable speed mode allow for swift transition between fruit types, making it suitable for diverse processing needs in the food industry.Q: When should maintenance be performed on the machine, and how easy is the process?

A: Routine maintenance can be scheduled as per usage intensity. The machine features an automatic lubrication system and is easy to dismantle and clean, ensuring minimal downtime. Spare parts and a user manual are included for further convenience.Q: Where can this fruit processing machinery be installed and used?

A: Designed for fruit processing factories and broader food industry facilities, the floor-mounted, forklift-compatible machine suits large-scale operations. It operates efficiently in ambient humidity below 95% and temperatures between 0C50C.Q: What steps are involved in the fruit processing cycle from input to output?

A: Fruits are loaded via the 300 mm inlet onto a belt conveyor, washed, sorted, ground, and pulped automatically. The machine utilizes digital PLC controls for streamlined processing, delivering finished, hygienic output through a 400 mm outlet in approximately 30 minutes per cycle.Q: How does the machine benefit fruit processors in terms of efficiency and output quality?

A: With efficient handling of up to 5000 kg/hr, low water consumption (120 L/hr), and low noise levels (<70 dB), this automatic line minimizes labor, accelerates processing, and consistently delivers high-quality, hygienic productsboosting productivity and output quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Heating Oven

Price 7000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 218 pizza at a time Pcs/hr

Automatic : Yes

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Murukku Making Machine

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Capacity : 40 to 45 Kg/hr

Automatic : Yes

Mustard Oil Expeller

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 70 Kg/hr

Automatic : Yes

Wheat Kurdai Machine Rice Kurdai Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Capacity : 4045 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free