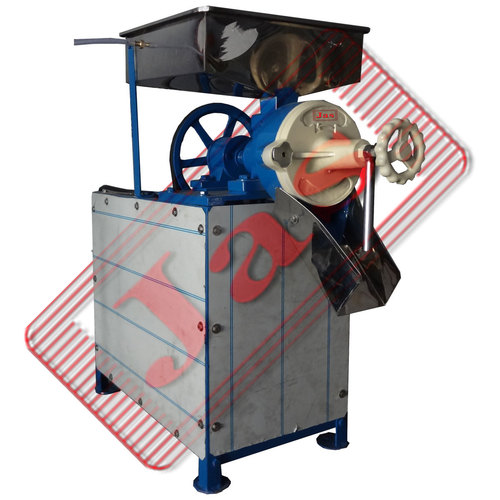

Industrial Automatic Idli Making Machine

Price 9000 INR/ Unit

Industrial Automatic Idli Making Machine Specification

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Industrial Automatic Idli Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Automatic Idli Making Machine

-

Automated Mixing and Fermentation: These machines often include systems for mixing the idli batter (a fermented blend of rice and urad dal) and managing the fermentation process. Some models also feature automatic ingredient dispensers.

-

Steam Cooking: The batter is poured into idli molds that are placed in a steam chamber. The machine controls the steaming process to ensure even cooking and proper texture.

-

Capacity and Efficiency: Industrial models come in various sizes, from small machines producing a few hundred idlis per hour to large-scale units that can make thousands. They are designed to handle large volumes efficiently.

-

Temperature and Time Control: Advanced machines have precise controls for temperature and steaming time, ensuring consistent quality and texture of the idlis.

-

Ease of Operation: Most machines are user-friendly, featuring digital controls and interfaces for setting parameters and monitoring the cooking process.

-

Cleaning and Maintenance: They are designed with hygiene in mind, with easy-to-clean parts and surfaces. Some models include self-cleaning functions.

-

Durability and Build: These machines are typically constructed from stainless steel and other durable materials to withstand continuous use in commercial settings.

Benefits:

- Consistency: Automatic machines provide uniform quality and texture in every batch.

- Efficiency: They reduce manual labor and speed up production, making them cost-effective in the long run.

- Hygiene: Automated systems often have better hygiene controls compared to manual methods.

- Scalability: Ideal for businesses looking to scale up production without compromising on quality.

Effortless Idli Production for Large-Scale Needs

This idli making machine automates the preparation process, efficiently meeting high-volume demand. Its advanced technology guarantees rapid, consistent results, making it an asset for industrial kitchens, catering services, and food processing industries. With a compact layout, it fits seamlessly into various production environments.

Sustainable and Cost-Efficient Operations

Engineered for eco-friendliness and lower energy consumption, the machine minimizes operational noise while delivering high output. Its robust design supports continuous, reliable performance, allowing businesses to reduce production costs and environmental footprint simultaneously.

FAQs of Industrial Automatic Idli Making Machine:

Q: How does the automatic idli making machine enhance production efficiency?

A: The automatic function streamlines the entire idli making process, significantly reducing manual labor and increasing output. This results in higher productivity and consistency, ideal for meeting large-scale demands with minimal effort.Q: What are the key features that make this machine eco-friendly and energy efficient?

A: The machine operates on low energy and produces minimal noise, thanks to advanced engineering and compact structure. These innovations contribute to lower electricity bills and a reduced environmental impact, supporting sustainable business practices.Q: When is the best time to use this automatic idli maker in operations?

A: The machine is designed for continuous use and is particularly beneficial during peak production periods or events requiring large quantities of idlis in a short timeframe. Its reliability ensures smooth operation throughout high-demand hours.Q: Where can the Industrial Automatic Idli Making Machine be installed?

A: Due to its compact structure, the machine can be installed in a variety of settingsindustrial kitchens, catering units, commercial canteens, and food processing areas with sufficient power supply (230/440 Volt).Q: What is the process of making idlis using this automatic machine?

A: Operators load the prepared idli batter into the machine, which then automates the pouring, steaming, and ejection sequence. The streamlined operation delivers perfectly cooked idlis in each cycle, ensuring uniform quality and shape.Q: How does using this machine benefit businesses such as distributors and wholesalers?

A: It enables bulk production at a lower operational cost, enhancing profitability for distributors, wholesalers, manufacturers, and retailers. With consistent output and reduced labor requirements, businesses can fulfill large orders promptly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Idli Dosa Batter Machine Category

Instant Idly Batter Grinding Machines

Price 24000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Capacity : 30250 Kg/hr

Idli Dosa Batter Machine

Price 26000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Low Noice, ECO Friendly, High Efficiency

Voltage : 420 Volt (v)

Automatic : Yes

Capacity : 50 to 60 Kg/hr

Edli Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 220/440 Volt (v)

Capacity : 36192 Idlis/batch Pcs/hr

Hotel Dosa Plate

Price 6100 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free