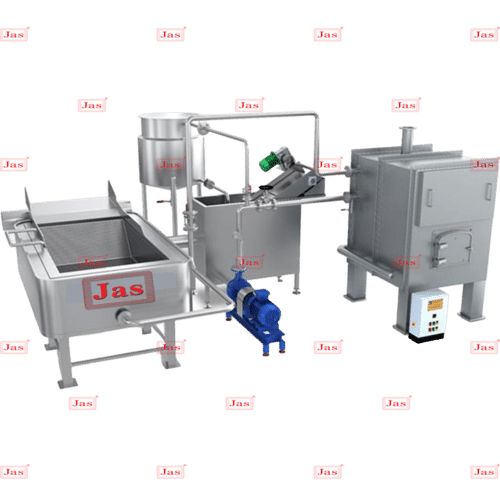

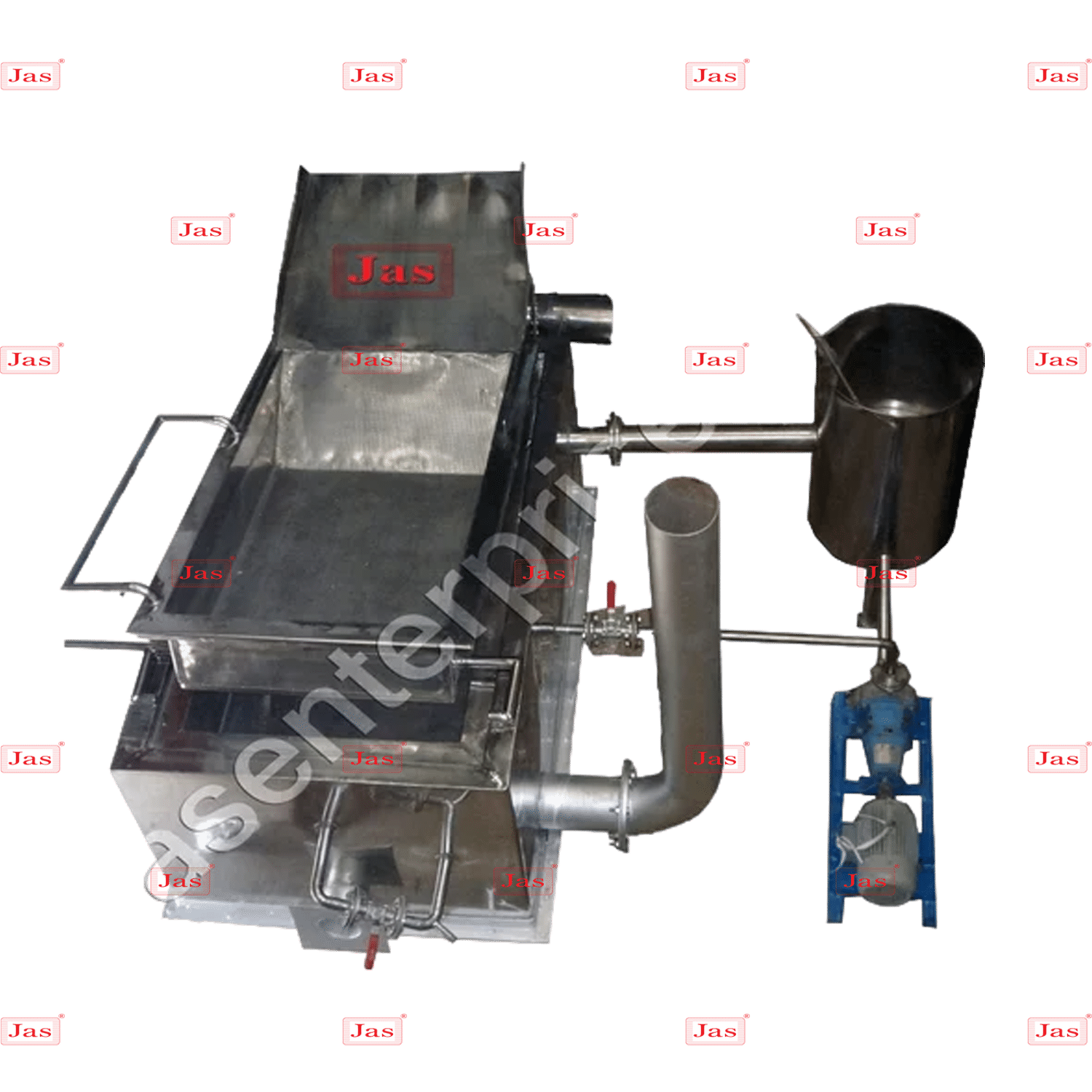

Industrial Frying Equipment

Price 10000 INR/ Unit

Industrial Frying Equipment Specification

- Capacity

- 12-32 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Industrial Frying Equipment Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Frying Equipment

Types of Industrial Frying Equipment

-

Batch Fryers:

- Description: These fryers cook food in batches. They are suitable for small to medium-sized operations.

- Features: Adjustable temperature controls, timers, and sometimes automated lifting systems for baskets.

-

Continuous Fryers:

- Description: Designed for high-volume production, these fryers have a conveyor belt or chain that moves food through the fryer continuously.

- Features: Automated temperature control, filtration systems, and often advanced features for precise cooking and oil management.

-

Deep Frying Stations:

- Description: Integrated systems that may include multiple fryers or compartments, often used in fast-food restaurants.

- Features: High capacity, multiple baskets, and sometimes integrated filtration systems.

-

Vacuum Fryers:

- Description: Operate under reduced pressure to fry foods at lower temperatures, preserving flavors and nutrients better.

- Features: Energy-efficient, often used for high-end products or specialty items.

-

Pressure Fryers:

- Description: Fry food under pressure to cook it faster and often result in a crispier texture.

- Features: Pressure control, temperature regulation, and safety mechanisms.

Key Features to Consider

- Temperature Control: Accurate and consistent temperature management is crucial for quality and safety.

- Filtration Systems: Many fryers include built-in oil filtration to extend oil life and reduce costs.

- Capacity and Size: Depending on your production volume, you may need a fryer that handles a large quantity of food.

- Energy Efficiency: Modern fryers often come with energy-saving features to reduce operational costs.

- Ease of Cleaning: Look for fryers with removable parts or self-cleaning features for convenience and hygiene.

Eco-Friendly and Efficient Performance

The Industrial Frying Equipment is engineered to minimize environmental impact while maximizing energy efficiency. Its lower energy consumption doesnt compromise on the output, making it ideal for sustainable food processing. The compact design ensures optimal utilization of space, whether in a large-scale factory or a mid-sized kitchen.

Versatile Applications Across the Food Industry

Suitable for distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers, this equipment meets versatile frying requirements. Its high efficiency and automatic functionality streamline food production, ensuring a consistent frying process every time.

FAQs of Industrial Frying Equipment:

Q: How does the automatic feature of the industrial frying equipment work?

A: The automatic feature streamlines the frying process by controlling temperature, frying time, and oil levels. This ensures food is cooked evenly and consistently with minimal manual intervention, reducing labor costs and human error.Q: What are the key benefits of using this equipment in a food production facility?

A: Benefits include high frying efficiency, lower energy consumption, a compact structure for easy installation, and eco-friendly operation. Additionally, it produces minimal noise, making the working environment more comfortable.Q: When is the ideal time to invest in industrial frying equipment?

A: Investing in this equipment is ideal when your production demands consistent quality, increased output, and efficiency, or when you are looking to modernize your facility with energy-saving and sustainable machinery.Q: Where can this industrial frying equipment be installed?

A: Its compact structure allows for easy installation in various settings, including large factories, commercial kitchens, and mid-sized food processing units throughout India.Q: What is the usage capacity of this frying equipment?

A: The fryer supports a production capacity of 12 to 32 kg per hour, making it suitable for small to medium-scale food processing and catering operations.Q: Which process steps does the equipment automate?

A: The equipment automates oil heating, temperature monitoring, frying, and food removal, streamlining production and ensuring high output with consistent results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Flavor Applicators

Price 20000.00-230000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440

Automatic : Yes

Capacity : 15 to 180 kg/batch Kg/day

Mustard Sauce Making Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 440 Volt (v)

Capacity : 501000 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Mirchi Kandap Machine 3 Bars

Price 41000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Capacity : 200 kg per hr Kg/hr

Green Chili - Onion Choppers

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency, Compact Structure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free