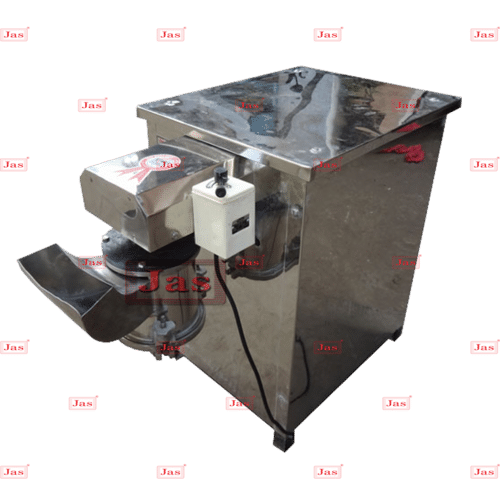

Industrial Murukku Making Machine

Price 50000 INR/ Unit

Industrial Murukku Making Machine Specification

- Capacity

- 40-45 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Industrial Murukku Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Industrial Murukku Making Machine

Types of Industrial Murukku Machines:

-

Semi-Automatic Machines:

- Require manual input for certain processes like mixing or packaging.

- Suitable for medium-sized businesses.

-

Fully Automatic Machines:

- Handle the entire production process, from mixing to shaping to frying.

- Ideal for large-scale production facilities.

Key Features to Look For:

-

Capacity:

- Machines come in various sizes and capacities. Choose one based on your production needs (e.g., kilograms per hour).

-

Material:

- Machines are usually made from stainless steel to ensure durability and ease of cleaning.

-

Shaping Mechanism:

- Different machines offer various shaping options (e.g., traditional spiral shapes, ribbon shapes). Some have interchangeable molds for flexibility.

-

Temperature Control:

- For frying units, precise temperature control is essential to ensure consistent quality.

-

Ease of Operation:

- Look for user-friendly controls and easy maintenance features.

-

Safety Features:

- Ensure the machine has necessary safety mechanisms to prevent accidents.

Efficient Snack Production

With automatic functionality and high efficiency, this murukku machine ensures consistent outputs ideal for commercial operations. Its compact structure accommodates various production environments, ensuring optimal utilization of space and effortless integration.

Eco-Friendly and Economical

The machine boasts lower energy consumption and operates quietly, contributing to an eco-conscious manufacturing process. These features allow businesses to reduce operational costs while supporting sustainability initiatives in food production.

FAQs of Industrial Murukku Making Machine:

Q: How does the Industrial Murukku Making Machine function automatically?

A: The machine utilizes advanced controls and automated mechanisms to mix, extrude, and shape murukku efficiently. This automation minimizes manual intervention, improving productivity and consistency across batches.Q: What is the production capacity of the murukku making machine?

A: The machine is capable of producing between 40 and 45 kilograms of murukku per hour, making it an excellent choice for businesses aiming for moderate to large-scale snack manufacturing.Q: When should I consider using this machine for my production needs?

A: You should consider the Industrial Murukku Making Machine when seeking to scale up production, improve output quality, and lower energy costs. Its reliable automated processes are ideal for meeting increased demand during peak seasons.Q: Where can this machine be integrated within a snack production facility?

A: Designed with a compact structure, the murukku making machine can be accommodated in both small and large-scale manufacturing units. Its versatility allows for easy installation in various industrial settings across India.Q: What benefits do the eco-friendly and low-noise features offer businesses?

A: These features enhance workplace comfort by reducing emissions and noise pollution, while also lowering energy bills. Adopting such machinery can support sustainability goals and improve employee satisfaction.Q: How is the process of making murukku optimized by this machine?

A: Automated mechanisms ensure uniform mixing, shaping, and output, resulting in consistent product quality and efficient use of raw materials. This reduces waste and ensures reliable results for every batch.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Snacks Making Machine Category

Industrial Popcorn Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 0.5 to 1 Horsepower (HP)

Voltage : 110440 Volt (v)

Control System : Manual

Popcorn Popper

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 0.5 to 1 Horsepower (HP)

Voltage : 110440 Volt (v)

Control System : Manual

Fryums Making Machine

Price Range 900000.00 - 1500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 15 TO 30 Horsepower (HP)

Voltage : 110440 Volt (v)

Control System : PLC Control

Corn Snacks Machine

Price Range 400000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 15 TO 30 Volt (v)

Voltage : 110440 Volt (v)

Control System : PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free