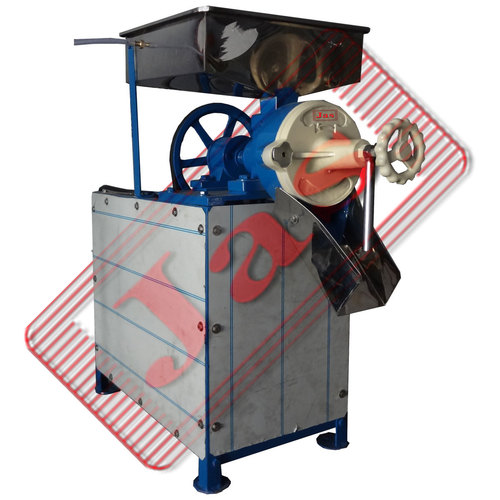

Kitchen Equipment Idly Plant

Price 11000 INR/ Unit

Kitchen Equipment Idly Plant Specification

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Kitchen Equipment Idly Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Kitchen Equipment Idly Plant

-

Soaking and Grinding: Rice and urad dal are soaked separately, then ground into a smooth batter. Some plants use industrial grinders for this step to ensure consistency and efficiency.

-

Fermentation: The batter is left to ferment, which is crucial for the idlis to rise and develop their characteristic texture. In a commercial plant, this might involve controlled temperature fermentation tanks.

-

Steaming: The fermented batter is poured into idly molds and steamed. Large-scale idly plants use industrial steaming equipment to handle high volumes of batter.

-

Cooling and Packaging: Once steamed, the idlis are cooled and then packaged for distribution. Some plants also produce idli batter for customers to cook at home.

These plants streamline the production process to meet the high demand for idlis, especially in areas where this dish is a staple food. If youre looking to start or understand more about an idly plant, focusing on efficiency in grinding, fermentation control, and steaming will be key.

Eco-Friendly Efficiency

This Idly Plant combines high efficiency with eco-friendly operation, reducing energy wastage and minimizing environmental impact. Its automatic features streamline the cooking process, making it ideal for kitchens aiming for sustainability and productivity. The low noise level delivers a quieter workspace, enhancing overall user comfort without sacrificing performance.

Compact and Versatile Design

Engineered with a compact structure, the Idly Plant fits easily into commercial kitchens with space constraints. Despite its small footprint, it boasts robust construction and reliable performance. The automatic controls simplify operation, and the system is adaptable for use by various scales of food service providers across India.

FAQs of Kitchen Equipment Idly Plant:

Q: How does the Kitchen Equipment Idly Plant support eco-friendly cooking?

A: This idly plant integrates materials and operations that minimize resource consumption, producing less waste and operating with lower energy requirements. Its design focuses on reducing environmental impact while maintaining efficient output.Q: What are the advantages of its compact structure in commercial kitchens?

A: The compact design enables easy installation, even in kitchens where space is limited. It helps maximize workspace utilization without compromising on performance or capacity, making it ideal for busy commercial environments.Q: When should the Idly Plant be used for optimal efficiency?

A: It is best employed during peak kitchen hours or large-scale meal preparation, as its high efficiency and automatic operation help streamline production and save time, especially valuable in high-demand situations.Q: Where can I purchase the Kitchen Equipment Idly Plant in India?

A: This product is available through a broad network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India, ensuring accessible procurement for businesses nationwide.Q: What is the process for using this automatic Idly Plant?

A: Simply load the idly batter into the trays, set the automatic controls, and the machine will handle the cooking process with minimal supervision, guaranteeing consistent results and reducing manual effort.Q: How does the lower energy consumption benefit users?

A: Lower energy consumption significantly reduces operating costs over time, making the plant economical for commercial kitchens. It also contributes to environmentally responsible operation, aligning with sustainability goals.Q: What features make this machine suitable for export and large-scale distribution?

A: Its durable construction, automatic controls, and compatibility with both 230 and 440 volt power supplies, coupled with standardized manufacturing processes, make it ideal for export and broad distribution through various channels in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Idli Dosa Batter Machine Category

Steam Dhokla and Idli Machine

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Computerized : No

Idli Dosa Batter Machine

Price 26000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 420 Volt (v)

Feature : Low Noice, ECO Friendly, High Efficiency

Automatic : Yes

Computerized : No

Edli Machine

Price 10000 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 220/440 Volt (v)

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Hotel Dosa Plate

Price 6100 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS