Mini Pulverizers

Mini Pulverizers Specification

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic

- Yes

- Installation Type

- Free Stand

- Warranty

- One year against manufacturing defects at our site, except all wear and tear parts.

Mini Pulverizers Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Month

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, All India, South India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Delhi, Gujarat, Karnataka, North India, Kerala, Central India, Odisha, West India, Chhattisgarh, Uttar Pradesh

- Certifications

- ISO 9001

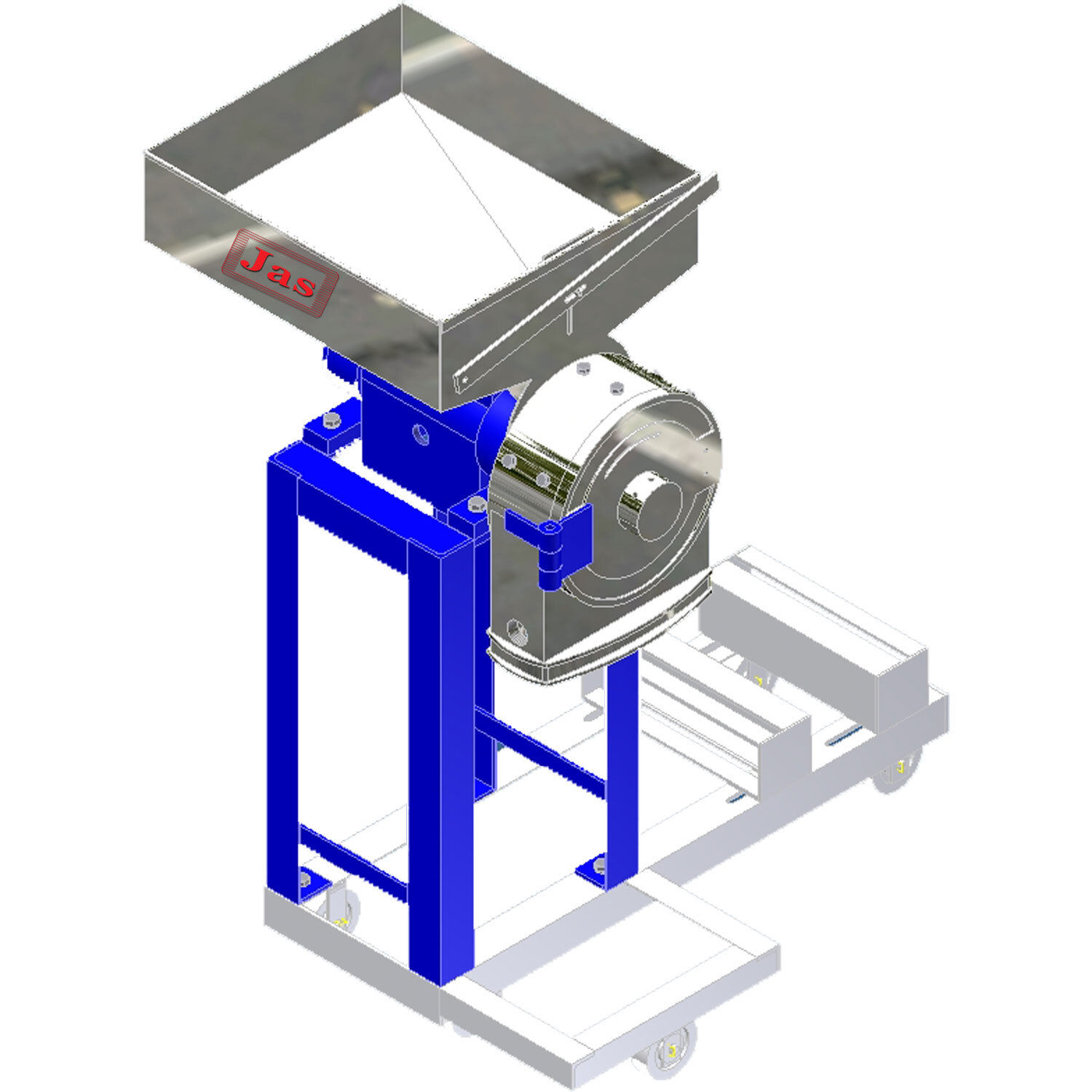

About Mini Pulverizers

Avail from us, a wide array of mini pulverizers that is designed to offer effective and continuous grinding. The Jas wings mini pulverizer comprises of a heavy duty cast iron or stainless steel body, which comprises of a feeding hopper, with a feed regulator slide. The mini pulverizer body is inlaid with a delivery trough attached at the bottom, with a delivery trough attached at the discharged end. The rotor & beater are mounted on shaft, running in ball bearing housing at a speed of 4500-5000 R.P.M. The whole unit is mounted on a heavy duty mild steel fabricated stand.

Key Features of mini pulverizers:

Unique and Reliable Design

- The Miniseries Pulverizers are highly effective as well as nonstop continuous pulverizing process.

- Compact size

- Dust free operation

- Ideal for dry crushing

- Increased production leading to faster return on the investments

- Hardened & fully machined beaters thus less wear & Terre.

- Single pieces grinding chamber no separate joints of fabrication for out late.

- Capacity: 2 - 100 Mesh

- Brand: Jas

- Grade: Automatic, Semi-Automatic

Advanced Stainless Steel Construction

The mini pulverizers are built from high-grade stainless steel, ensuring optimal hygiene and long-lasting durability. Their robust construction makes them ideal for handling demanding grinding tasks across various industries while maintaining product integrity and safety.

Efficient Computerized Automation

Equipped with computerized features, these pulverizers simplify operations and enhance productivity. The automatic functions reduce manual intervention, deliver consistent results, and improve process accuracy, allowing for smoother and faster workflows.

Flexible Standing Installation

Designed for easy integration, the pulverizers adopt a free-standing installation type. This flexibility allows for simple setup and relocation, making them ideal for businesses seeking adaptable equipment for dynamic production environments.

FAQs of Mini Pulverizers:

Q: How does the automated and computerized feature of the Mini Pulverizer improve its operation?

A: The computerized and automatic system allows users to achieve consistent grinding results with minimal supervision. It streamlines the process, reduces errors, and increases overall productivity by automating key functions.Q: What materials can be processed using the stainless steel Mini Pulverizer?

A: The Mini Pulverizer is suitable for grinding a wide range of dry and semi-dry materials, making it ideal for applications in food processing, pharmaceuticals, chemicals, and other industrial sectors.Q: When can I expect warranty coverage for my Mini Pulverizer purchase?

A: A one-year warranty covers manufacturing defects from the date of purchase at our site. Please note, wear and tear parts are not covered under this warranty.Q: Where can the Mini Pulverizer be installed within my facility?

A: Thanks to its free-standing design, the pulverizer can be installed wherever there is sufficient floor space and access to power supply, providing flexibility in dynamic production settings.Q: What is the process for installation and setup of this machine?

A: Installation is straightforward. Place the free-standing unit at the desired location, ensure it is level, and connect it to a power source following the user manual. No complex assembly is required.Q: How can different types of businesses in India benefit from using this pulverizer?

A: Whether you are a distributor, exporter, manufacturer, retailer, supplier, trader, or wholesaler, the efficiency and reliability of the Mini Pulverizer can improve your production processes, deliver uniform product quality, and support business growth.Q: What regular maintenance is required to ensure optimal usage of the Mini Pulverizer?

A: Routine cleaning of grinding components and periodic inspection for wear items is recommended. As wear and tear parts are not covered under the warranty, timely replacement ensures uninterrupted performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Pulverizers Category

Jacketed Mini Pulverizers

Price Range 25000.00 - 55000.00 INR / Unit

Minimum Order Quantity : 1 Ohm

Material : Stainless Steel

Control System : Manual

Automatic : Yes

Installation Type : Free Stand

Semi Automatic Stainless Steel 2 In 1 Pulverizer Machine

Price Range 15000.00 - 40000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Control System : Manual

Automatic : Yes

Installation Type : Free Stand

Instant Wet Rice Grinder Machine

Price Range 15000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Control System : Manual

Automatic : Yes

Installation Type : Free Stand

Rice Flour Grinding Machine

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Control System : PLC Control

Automatic : Yes

Installation Type : Free Stand

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free