Moringa Leaves Powder Processing Plant

Price 550000 INR/ Piece

Moringa Leaves Powder Processing Plant Specification

- Phase

- Single Phase / Three Phase

- Automation Grade

- Semi Automatic

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 30-2500 Kg/hr

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Moringa Leaves Powder Processing Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 5-10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Moringa Leaves Powder Processing Plant

A Moringa Leaves Powder Processing Plant is a specialized industrial facility dedicated to the systematic and hygienic processing of fresh Moringa oleifera leaves into a fine, nutrient-rich powder. Moringa, often referred to as the "miracle tree," is highly valued for its exceptional nutritional and medicinal propertiesEfficient Moringa Leaf Processing

Our Moringa Leaves Powder Processing Plant streamlines the conversion of raw moringa leaves into fine, ready-to-use powder. Its stainless steel construction ensures hygiene and longevity, while semi-automatic controls deliver consistent results with minimal labor. The plant's eco-friendly and energy-efficient design fits modern sustainability goals without compromising on productivity or quality.

Versatile Operation and Capacity

The system accommodates a wide range of business needs, from small-scale operations processing 30 kg/hr to large factories handling up to 2500 kg/hr. The plant operates reliably on single or three-phase power supplies, making it adaptable to various industrial setups across India's regions.

FAQ's of Moringa Leaves Powder Processing Plant:

Q: How does the semi-automatic control system operate the Moringa Leaves Powder Processing Plant?

A: The plant features a manual control system, allowing operators to manage the processing stages efficiently. Without computerized or fully automatic controls, it ensures reliability and ease of maintenance while still delivering high output and consistent powder quality.Q: What is the process for converting moringa leaves into powder in this plant?

A: The plant involves cleaning, drying, pulverizing, and sieving moringa leaves. Each stage is precisely handled to preserve nutritional content and achieve a uniform, high-quality powder suitable for various industries.Q: When should maintenance be performed on the plant equipment?

A: Routine maintenance is recommended according to the manufacturer's guidelines, typically after set intervals of operating hours, to ensure optimal performance. The stainless steel build simplifies cleaning and reduces overall maintenance frequency.Q: Where is this plant most commonly used?

A: The processing plant is ideally suited for use in industrial facilities throughout India, serving distributors, exporters, manufacturers, suppliers, and retailers engaged in moringa powder production and supply.Q: What are the benefits of using this Moringa Leaves Powder Processing Plant?

A: Key advantages include eco-friendly operation, low noise levels, energy efficiency, compact structure, and a warranty against manufacturing defects. The plant enables consistent powder quality at various production scales.Q: How does the plant accommodate different voltage and phase requirements?

A: Designed for flexibility, the plant can operate with either 230V or 440V power supplies and supports both single and three-phase electrical setups, ensuring compatibility with varied electrical infrastructures.Q: What usage scenarios does the capacity range of 30-2500 kg/hr address?

A: With its broad capacity range, the plant is suitable for small-scale startups, medium enterprises, and large-scale industrial processors, ensuring scalable production that meets evolving business needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Idli Steamer Gas

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 24120 Idlis per batch (varies with model)

Feature : Other, Rust Proof, Durable Construction, Energy Efficient

Automatic : Yes

Industrial Mixer Grinder

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 220 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Automatic : Yes

Kaju Musta Making Machine

Price 40000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 1015 kg per batch Kg/hr

Automatic : Yes

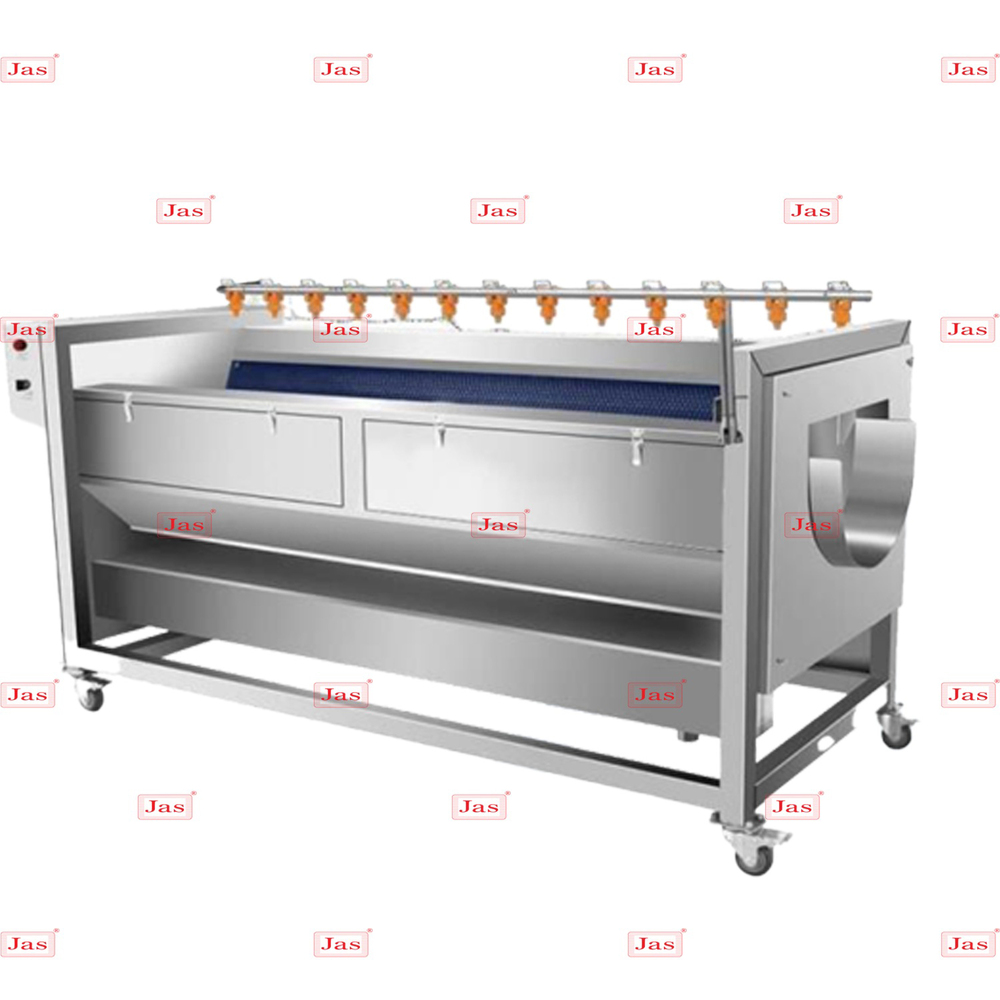

Onion Processing Machine

Price 550000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 302500 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS