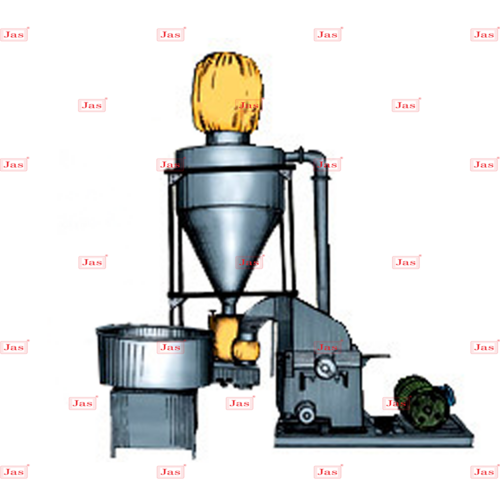

Multipurpose Dry and Wet Pulverizer

Price 25000 INR/ Unit

MOQ : 1 Piece

Multipurpose Dry and Wet Pulverizer Specification

- Material

- Stainless Steel

- Weight (kg)

- 65 Kilograms (kg)

- Automatic

- Yes

- Power

- 1500 Watt (w)

- Voltage

- 110 to 415 Volt (v)

- Dimension (L*W*H)

- 62 X 32 X 77 Centimeter (cm)

Multipurpose Dry and Wet Pulverizer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- Week

About Multipurpose Dry and Wet Pulverizer

Taken quality as a prime concern, we are involved in manufacturing and exporting tough built Multipurpose Pulverizer. To meet the international quality standards, this pulverizer is manufactured using high grade stainless steel that is procured from certified vendors of the market. Our offered pulverizer is thoroughly examined on various factors like superior finish and high strength. This Multipurpose Pulverizer is widely used for grinding various types of spices, sugar, betel nuts, poultry feeds and for allied food production.Striking characteristics:

- Simple installation

- Seamless finish

- Longer service life

- Rugged construction

Other details:

Key features of dry and wet pulverizer

- Unique and reliable design

- The multipurpose dry and wet pulverizers are highly effective as well as nonstop continuous pulverizing process.

- All contacting parts are aluminum and stainless steel no corrosion hazards.

- Multipurpose dry and wet pulverizers is not required any v belts thus less friction losses.

- Increased production leading to faster return on the investments

- All rotating parts are dynamical balanced for less vibration and higher performances.

- Low temperature grinding Jaslogy thus the original ingredient cannot destroy.

Application of dry and wet pulverizer

Multipurpose dry and wet pulverizers are exclusively meant for the grinding of wheat, maize, oat, pulses, other grains, chili, coriander, dry ginger, black pepper, turmeric and curry powders, tomato, wet rice, pulses, etc.. on a small scale basis.

Construction of dry and wet pulverizer

Multipurpose dry and wet pulverizers made from heavy duty mild steel fabricated body covered with stainless steel sheet. Aluminum grinding chamber lined with serrated wear steel plates, which protects the body from wear and tear. Grinding is done by a set of fixed better on a balanced rotor. A screen classifier forms the lower half of the grinding chamber.

Efficient Grinding for Multiple Applications

This pulverizer is engineered to handle both dry and wet grinding, enabling users to process hard spices, grains, wet pastes, and more with minimal effort. Its powerful motor and stainless steel body ensure consistent results in busy kitchens and industrial settings.

Automatic Operation and User-Friendly Design

The automatic functionality simplifies the grinding process, reducing manual effort and time spent. Its convenient dimensions and ergonomic construction increase operational efficiency, making it an asset for establishments seeking reliable and convenient food processing solutions.

FAQs of Multipurpose Dry and Wet Pulverizer:

Q: How does the multipurpose dry and wet pulverizer operate automatically?

A: This machine is equipped with an automatic system that manages the grinding process, allowing users to load ingredients and achieve consistent results without manual intervention. Its controls are user-friendly and designed for straightforward operation.Q: What types of materials can be processed using this pulverizer?

A: The pulverizer can efficiently handle both dry items like grains, spices, and seeds, as well as wet materials including pastes, fruits, and vegetables, making it suitable for a variety of culinary and industrial applications.Q: When is the best time to use the multipurpose pulverizer in a commercial setting?

A: Optimal use of the pulverizer is during food preparation or production periods that require quick processing of large quantities, such as restaurant peak hours or bulk operations in factories.Q: Where can this stainless steel pulverizer be sourced or purchased in India?

A: It is readily available through distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India, making it accessible for a wide range of customers and industries.Q: What is the process for cleaning and maintaining the pulverizer?

A: After use, the stainless steel components should be cleaned with mild detergent and water. Regular maintenance includes inspecting moving parts, ensuring proper lubrication, and checking electrical connections for safe and efficient operation.Q: How can the pulverizer be used to improve productivity in food processing?

A: The units high power and large processing capacity significantly reduce time and labor involved in grinding tasks, leading to smoother workflows and higher output in food-related businesses.Q: What are the key benefits of using a 1500-watt, stainless steel pulverizer?

A: Key advantages include durability, reliability, and versatility in handling various ingredients. Its high wattage ensures rapid grinding, while stainless steel construction offers hygienic processing and long-term use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Grinding, crushing and Pulverizing Machine Category

auto suction pulverizer

Price 197500 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Capacity : 50 to 1000 kg/hr

Color : Blue

Bottom Discharge Hammer Mill

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Capacity : 3035 Kg/hr

Color : Blue

Wood Hammer Mill

Price 239000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Color : Other, Sliver

Maize Grinding Hammer Mill

Price 15000.00-650000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Capacity : 20 to 2200 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free