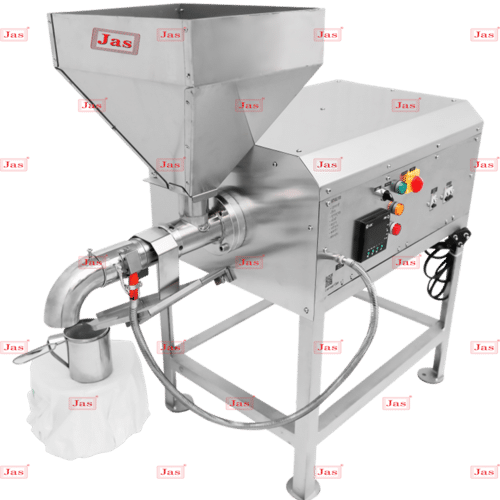

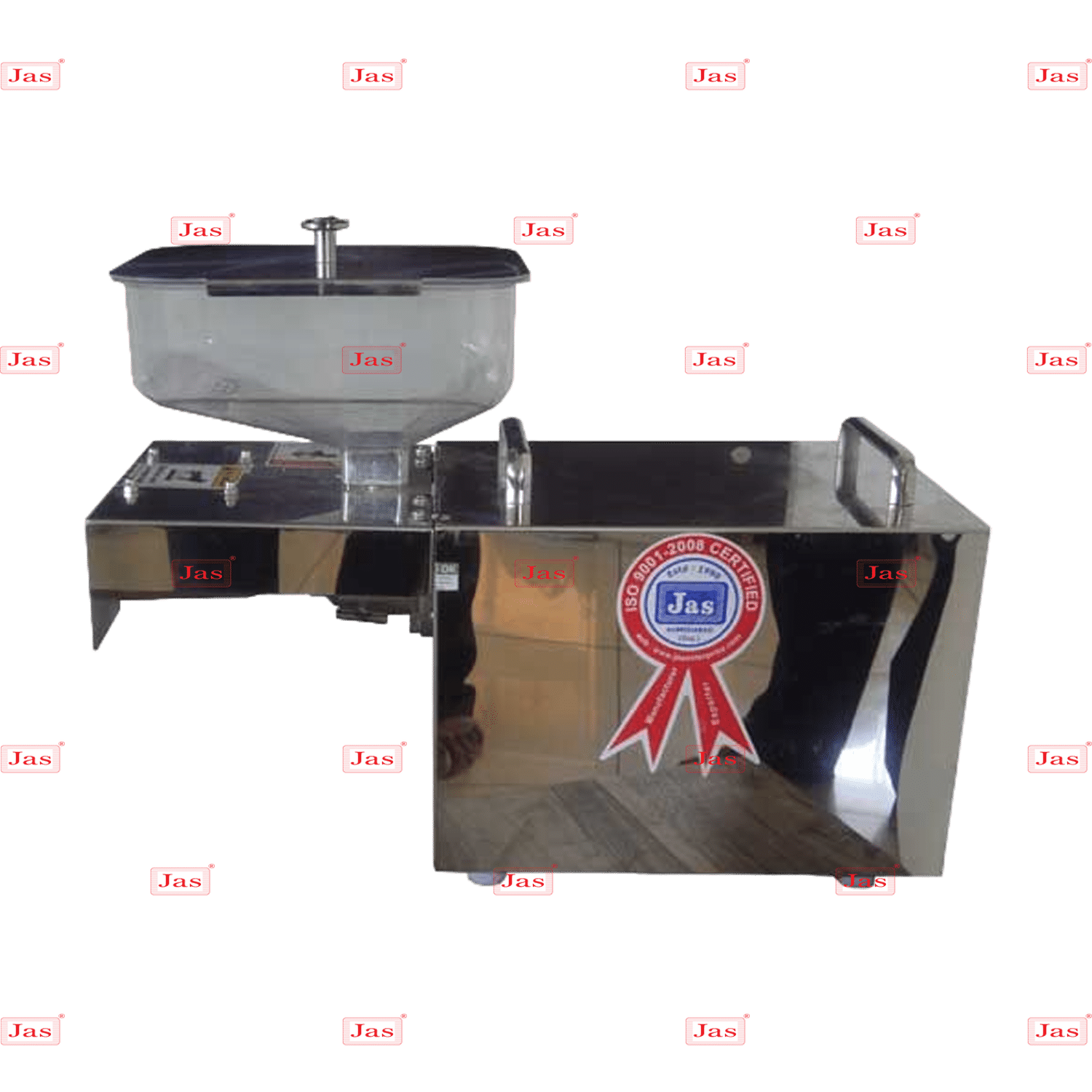

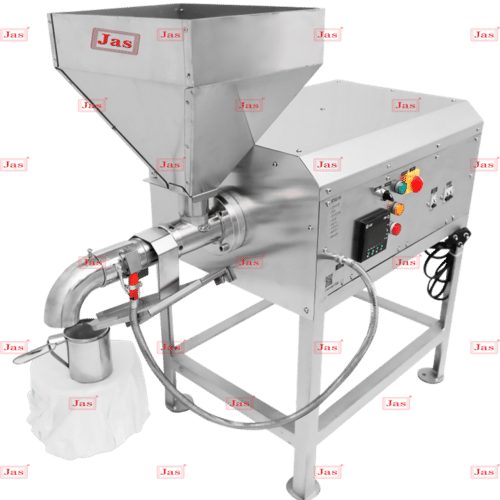

Oil Processing Machinery

Price 16000 INR/ Unit

MOQ : 1 Unit

Oil Processing Machinery Specification

- Power Source

- Electric

- Automation Grade

- Automatic

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 2-25 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Color

- Other

- Warranty

- 1 Year

Oil Processing Machinery Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Oil Processing Machinery

1 Seed Cleaning and Preparation Equipment- Seed Cleaners Remove impurities and foreign materials from seeds

- DehuskersHuskers Remove the outer husk or shell of seeds or nuts

- Crushers Break down seeds to facilitate oil extraction

2 Oil Extraction Machinery

- Expeller Press Uses mechanical pressure to extract oil from seeds or nuts Its a common method for many types of seeds and is often used in coldpressing

- Hydraulic Press Employs hydraulic pressure to extract oil typically used for highquality oils and smallerscale production

- Solvent Extractor Uses chemical solvents like hexane to extract oil from seeds This method is efficient for extracting oil from oilseeds that have a lower oil content

3 Oil Refining Equipment

- Degumming Unit Removes phosphatides and other gums from crude oil

- Neutralizer Neutralizes free fatty acids to improve oil quality and shelf life

- Bleaching Unit Removes pigments and impurities to improve the color and clarity of the oil

- Deodorizer Eliminates unwanted odors and flavors from the oil typically using steam distillation

4 Oil Filtering and Storage

Filtration Systems Remove any remaining particulates or impurities from the oil

Storage Tanks Store the refined oil before it is packaged or further processed

5 Other Related Equipment

- Heat Exchangers Regulate temperatures during various processing stages

- Centrifuges Separate solids from liquids and can be used in both extraction and refining processes

- Vacuum Pumps Used in processes like deodorization to maintain low pressure and prevent oil degradation

Efficient Industrial Oil Processing

Experience streamlined oil extraction with our automatic processing machinery, designed to optimize industrial output while prioritizing eco-friendliness and minimal energy consumption. Equipped with a PLC control system for precision, this machine ensures consistent results with reduced operational noise, making it suitable for various manufacturing environments across India.

Advanced Features for Reliable Performance

Our stainless steel oil processing machine combines high efficiency with a compact structure, making it an ideal fit for limited spaces. It delivers low noise output and consumes less energy without compromising on production quality. Every unit ships with a comprehensive 1-year warranty, guaranteeing dependable performance and customer confidence.

FAQs of Oil Processing Machinery:

Q: How does the automatic oil processing machinery operate?

A: The machinery utilizes a PLC-controlled system for seamless automation, requiring minimal manual input. Users simply load the raw material, set the desired process parameters, and the machine manages the extraction efficiently with consistent results.Q: What types of industries commonly use this oil processing machine?

A: This machinery is commonly used in industrial sectors involving food processing, pharmaceutical manufacturing, and other applications where oil extraction from seeds or nuts is required.Q: When should I consider routine maintenance for the equipment?

A: It is advisable to perform routine maintenance checks every three to six months, depending on usage intensity. Regular inspection helps maintain operational efficiency and prolongs machine lifespan.Q: Where is the oil processing machinery available for purchase in India?

A: You can procure this machinery from authorized distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. Reach out to our network partners for sales and support.Q: What is the step-by-step process of oil extraction with this machine?

A: The process involves loading the input material into the machine, selecting the process settings through the PLC control, and initiating the extraction. The system efficiently separates and collects oil, while ensuring minimal waste and noise.Q: How is the machine designed to benefit users?

A: Users benefit from high efficiency, lower energy consumption, eco-friendly operation, and reduced noise. The compact structure also saves floor space and installation is straightforward, making it suitable for diverse industrial setups.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Oil Mill, Oil Extraction Machinery & Equipment Category

Mini Screw Press Oil Extraction Machine

Price Range 20000.00 - 130000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 2 to 20 Kg/hr

Automatic : Yes

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Soybean Oil Mill Machine

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 20 Ton/day

Automatic : Yes

Warranty : One year against manufacturing defects at our site

Herbal Oil Extraction Machine

Price 16000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 225 Kg/hr

Automatic : Yes

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free