Onion Dryer Machine

Price 390000 INR/ Unit

MOQ : 1 Unit

Onion Dryer Machine Specification

- Capacity

- 30-2500 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Onion Dryer Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Onion Dryer Machine

How It Works

- Preparation: Onions are first peeled and often cut into smaller pieces to ensure even drying.

- Loading: The prepared onion pieces are loaded into the dryer machine.

- Drying Process: The machine uses methods such as hot air, infrared, or other forms of heat to remove moisture from the onions. This can be done in various stages, depending on the machine's design.

- Cooling and Packaging: Once dried, the onions are cooled and then packaged to prevent moisture absorption.

Types of Onion Dryer Machines

- Hot Air Dryers: Use heated air to dry onions. They are commonly used due to their efficiency and ease of use.

- Drum Dryers: Employ rotating drums to expose onions to heat, often resulting in a more uniform drying process.

- Freeze Dryers: Use a process of freezing the onions and then removing the moisture through sublimation. This method preserves more flavor and nutrients but is more expensive.

- Tunnel Dryers: These are large-scale systems where onions pass through a heated tunnel on conveyor belts, suitable for high-volume processing.

Advanced Drying Technology

Utilizing cutting-edge mechanisms, the Onion Dryer Machine ensures quick and uniform drying of onions. Its automatic function streamlines the process, reducing manual intervention and optimizing throughput for businesses with varying production scales.

Optimal Efficiency and Energy Savings

Designed with energy conservation in mind, this machine minimizes electricity usage while maintaining high output. Its compact structure allows for easy installation within limited spaces, making it an attractive option for both small-scale and larger operations.

FAQs of Onion Dryer Machine:

Q: How does the Onion Dryer Machine operate automatically?

A: The machine leverages integrated sensors and programmed controls to automate the entire drying process. This reduces manual intervention, ensures precise drying parameters, and increases overall production efficiency.Q: What voltage options are available for the Onion Dryer Machine?

A: The Onion Dryer Machine is compatible with both 230 Volt and 440 Volt electrical supplies, offering flexibility for installation in different industrial and commercial settings across India.Q: When should I use a high-capacity Onion Dryer Machine?

A: A high-capacity model, suitable for 302,500 kg/hr, should be used when consistently large volumes of onions need to be processed, such as in industrial food production facilities, commercial kitchens, or large agricultural operations.Q: Where can I purchase or source the Onion Dryer Machine in India?

A: The Onion Dryer Machine is available from a wide range of suppliers including distributors, exporters, manufacturers, retailers, traders, and wholesalers throughout India. You may contact them directly for quotations and detailed product information.Q: What is the process for drying onions using this machine?

A: Onions are loaded into the machine, which automatically handles the drying using controlled heat and airflow. The process ensures uniform moisture removal, producing dehydrated onions suitable for direct use or further processing.Q: What are the main benefits of using this machine for onion drying?

A: Key benefits include ECO-friendly operation, low noise levels, minimized energy consumption, compact structure for easy placement, and high efficiencyresulting in reduced operational costs and consistent product quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Food Processing Machinery Category

Popcorn Making Machine With Tilting Kettle

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : Yes

Voltage : 220V

Material : Stainless Steel

Installation Type : Other, Freestanding

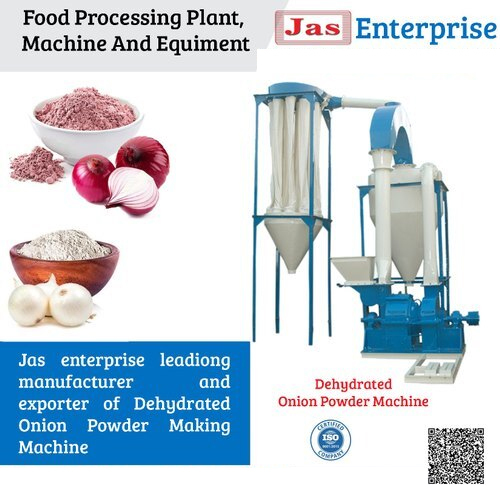

Dehydrate Onion Powder Manufacturing Plant

Price 170000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Material : Stainless Steel

Installation Type : Free Stand

Screw Type Juice Extractor

Price 9000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Material : Stainless Steel

Installation Type : Free Stand

Cheese Grater

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 110 to 440 Volt (v)

Material : Stainless Steel

Installation Type : Free Stand

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS