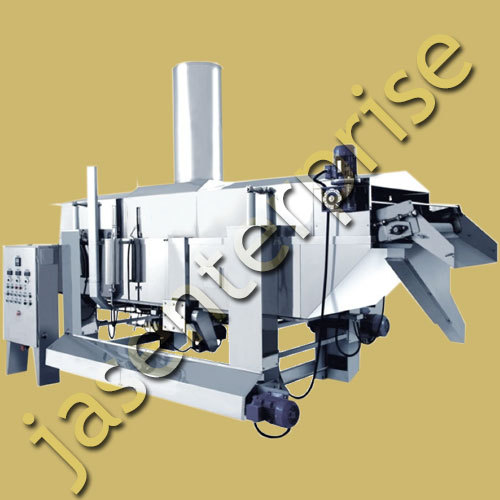

Potato Chips Making Automatic Machine

Price 25500 INR/ Piece

Potato Chips Making Automatic Machine Specification

- Phase

- Single Phase

- Frequency

- 50-60 Hertz (HZ)

- Automation Grade

- Semi Automatic

- Capacity

- 200-1000 Kg/hr

- Voltage

- 230 Volt (v)

- Power

- 0.5-2

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Potato Chips Making Automatic Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Potato Chips Making Automatic Machine

Streamlined Semi-Automatic Potato Chips Production

Unlock high efficiency in snack production with this user-friendly, semi-automatic potato chips making machine. Its robust construction and cutting-edge features facilitate consistent output from 200 to 1000 kg per hour, meeting the demands of businesses large and small. The compact structure and low-noise operation allow for seamless integration into various production environments, maximizing productivity while minimizing environmental impact.

Economical and Eco-Friendly Operation

Experience significant energy savings and reduced noise levels thanks to the machine's innovative design. Rated for lower energy consumption, it supports sustainable production without compromising on output quality. Its eco-friendly technology aligns with modern food processing standards, providing a responsible solution for businesses seeking to lower operational costs and environmental footprint.

FAQ's of Potato Chips Making Automatic Machine:

Q: How does the semi-automatic potato chips making machine operate?

A: The machine is designed to automate key stages of potato chips production, such as slicing and frying, while requiring manual input for certain processes like loading and unloading. It operates on a single-phase, 230V power supply and is user-friendly for quick setup and efficient daily operation.Q: What is the production capacity of this potato chips machine?

A: The machine can process between 200 and 1000 kilograms of potatoes per hour, making it suitable for small-scale to mid-size food businesses. Capacity may vary depending on the size of the batch and the specific operational settings used.Q: When is the warranty applicable, and what does it cover?

A: The product comes with a one-year warranty against manufacturing defects on our side. This warranty ensures repair or replacement of faulty components within the specified period, beginning from the date of purchase.Q: Where can this potato chips making machine be purchased?

A: The machine is available through a wide distribution network that includes distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. Interested buyers can contact these channels for purchasing and after-sales support.Q: What is the process for making potato chips using this machine?

A: The process typically involves washing, peeling, slicing, and frying potatoes using the machine's semi-automatic modules. Operators load potatoes into the machine, monitor settings, and collect the finished chips from designated output areas.Q: How can this machine benefit my food production business?

A: The machine offers several benefits, including high efficiency, lower noise levels, compact structure, reduced energy consumption, and consistent chip quality. These features collectively contribute to increased productivity, reduced operational costs, and a smaller environmental footprint.Q: Is this potato chips making machine suitable for different production environments?

A: Yes, the compact and eco-friendly design allows this machine to fit into various scales of production, from small snack shops to larger commercial units, without requiring extensive modifications to existing facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Potato Chips Making Machines Category

Continuous Potato Chips Fryer

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : Other, High Efficiency, Continuous Operation, Low Oil Consumption

Voltage : 380V / 415V

Material : Stainless Steel

Potato Chips Making Machines

Price 23000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : High Efficiency, ECO Friendly, Low Noice

Voltage : 420 Volt (v)

Material : Stainless Steel

Fully Automatic Potato Chips Plant

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

Voltage : 110440 Volt (v)

Material : Stainless Steel

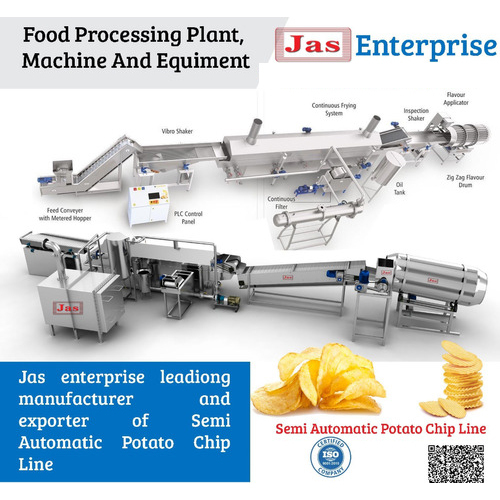

Semi-Automatic Potato Chip Line

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : Lower Energy Consumption, ECO Friendly, Compact Structure, High Efficiency, Low Noice

Voltage : 110 to 440 Volt (v)

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS