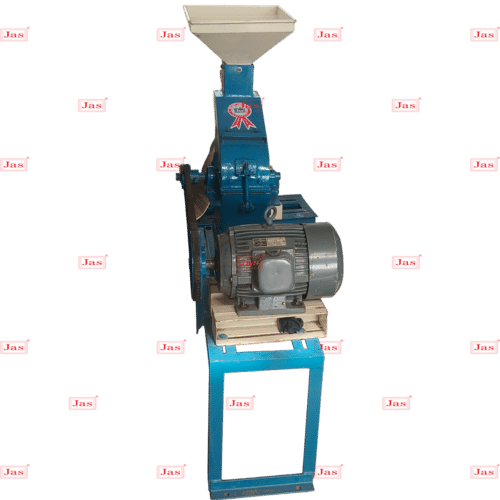

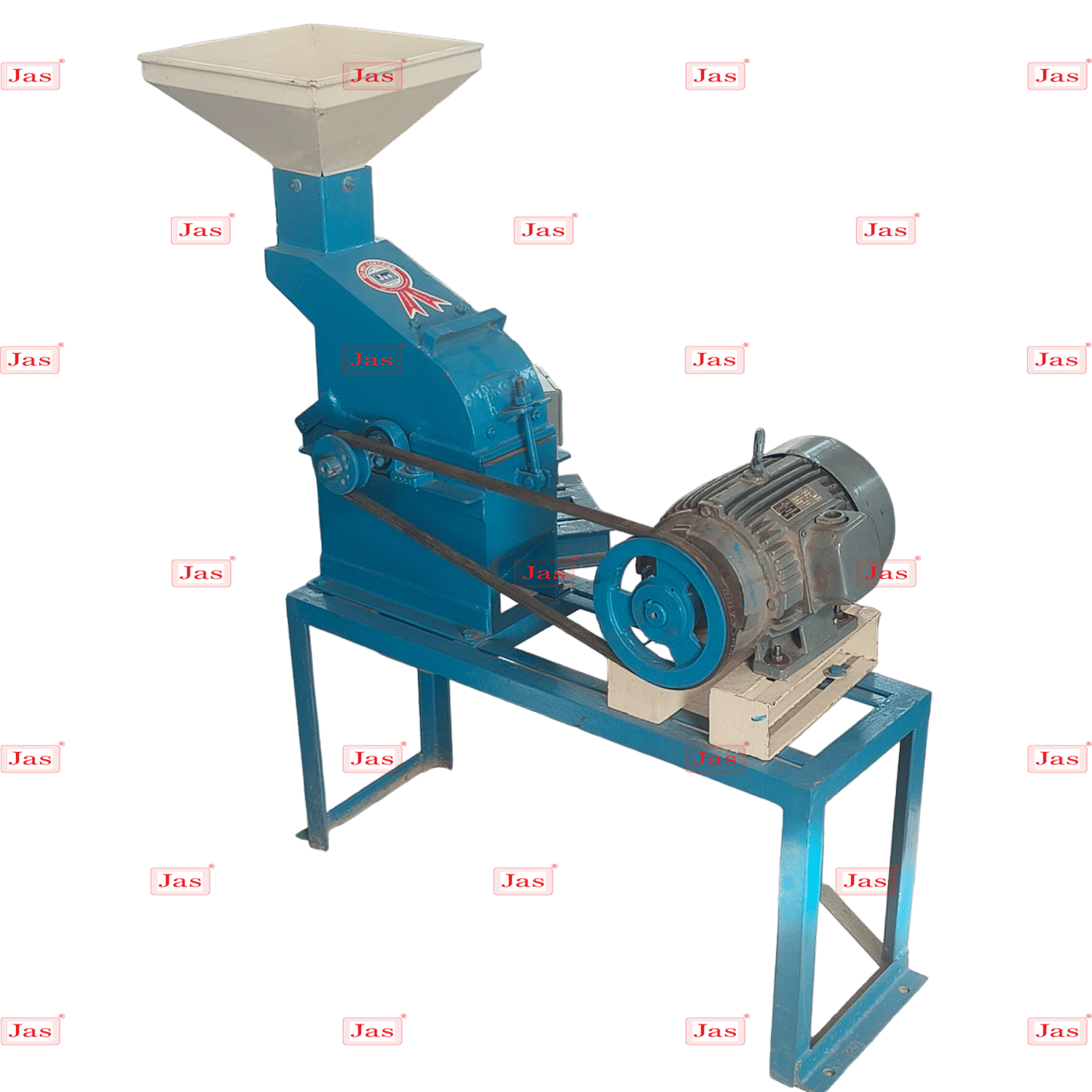

Pulverizer For Mineral Grinding

Price 18000 INR/ Unit

Pulverizer For Mineral Grinding Specification

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 20-2200 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 230/440 Volt (v)

- Feature

- High Performance, ECO Friendly, Low Noise, Lower Energy Consumption, High Efficiency

Pulverizer For Mineral Grinding Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Pulverizer For Mineral Grinding

-

Ball Mills: These are cylindrical devices filled with grinding media (usually steel or ceramic balls) and the material to be ground. The rotation of the cylinder causes the balls to fall and crush the material.

-

Rod Mills: Similar to ball mills but use long rods as grinding media. They are used for coarser grinding than ball mills.

-

Hammer Mills: These use high-speed rotating hammers to crush and grind materials. They are useful for materials that are brittle or less dense.

-

Vertical Roller Mills (VRM): These mills use a combination of compressive and shear forces to grind materials between a rotating table and stationary rollers. They are efficient for grinding very fine materials and have a smaller footprint compared to ball mills.

-

Impact Mills: These include pulverizers that use high-speed impact to break down materials. Examples include jet mills and impact crushers.

-

Attrition Mills: These mills use friction to grind materials. They are often used for very fine grinding and can be used with dry or wet materials.

-

Bead Mills: These use grinding beads suspended in a liquid to grind materials. They are commonly used for very fine and ultra-fine grinding.

Reliable Industrial Mineral Grinding

Our Pulverizer for Mineral Grinding stands out for its ability to deliver consistent, high-quality pulverizing for a wide range of mineral types. Its stainless steel body ensures durability while the automated PLC control system allows for effortless operation. The machine offers flexibility for small-scale to large-scale needs, catering to diverse industrial demands.

Efficient and Eco-Friendly Operation

Equipped with cutting-edge energy-saving features, the pulverizer is designed to operate efficiently with lower power consumption, helping industries reduce operational costs and environmental impact. Its low-noise mechanism further enhances workplace comfort, making it a preferred choice for modern, sustainable factories.

FAQs of Pulverizer For Mineral Grinding:

Q: How does the pulverizer for mineral grinding operate?

A: The pulverizer operates using a PLC-controlled automatic system to grind minerals into fine powder. Its powerful motor runs on either 230 or 440 volts, enabling it to handle material capacities from 20 to 2200 Kg/hr with minimal manual intervention.Q: What materials can this pulverizer process?

A: This machine is specifically engineered for grinding a variety of minerals, utilizing its stainless steel design to manage abrasive materials effectively and ensure contamination-free output.Q: When is it ideal to use this pulverizer in industrial applications?

A: The pulverizer is optimal for use in production environments that require consistent, high-capacity mineral grinding, such as cement plants, chemical processing, and mineral extraction industries.Q: Where can I purchase or source the pulverizer for mineral grinding in India?

A: You can acquire this equipment from authorized distributors, manufacturers, exporters, suppliers, retailers, traders, and wholesalers across India, catering to both domestic and international industrial needs.Q: What benefits does this pulverizer offer compared to conventional models?

A: This model provides significant advantages, including enhanced energy efficiency, reduced operational noise, automatic control, and eco-friendly performance, all of which contribute to improved productivity and lower maintenance costs.Q: How is maintenance carried out on this machine?

A: Maintenance is straightforward due to the machines robust stainless steel construction and automated controls, requiring only periodic routine checks and cleaning to ensure sustained high performance and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Stainless Steel Wet Grinder

Price 18000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 15450 Kg/hr

Voltage : 230/440 Volt (v)

Wheat Grinding Machine

Price Range 18500.00 - 88000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Hammer Mills

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 6065 Kg/hr

Voltage : 110 to 415 Volt (v)

Sugar Grinding Machine

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 3035 Kg/hr

Voltage : 110 to 415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free