Semi Automatic Chips Making Machine

Price 25000 INR/ Unit

Semi Automatic Chips Making Machine Specification

- Product Type

- Chips Making Machine

- General Use

- Food Processing

- Material

- Stainless Steel

- Type

- Food Processors

- Capacity

- 300-1000 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Semi Automatic Chips Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Semi Automatic Chips Making Machine

Key Components and Features

-

Feeding System: This part of the machine handles the raw potatoes or other vegetables. It often includes a hopper where the vegetables are loaded and an automatic feeder that transports them to the cutting section.

-

Cutting Mechanism: The machine usually features a slicer or dicer that cuts the vegetables into thin slices or desired shapes for chips. This part is often adjustable to produce different sizes or thicknesses.

-

Blanching Unit: Some machines have a built-in blanching section that briefly cooks the chips in hot water or steam to remove excess starch and improve texture.

-

Frying System: Semi-automatic machines may come with an integrated fryer or a system to transfer the sliced potatoes to an external fryer. The frying process can be monitored and adjusted manually.

-

Seasoning Application: After frying, chips often need to be seasoned. A semi-automatic machine might have a mechanism for applying seasoning or salt, but operators usually need to adjust and manage this process.

-

Cooling and Packaging: After frying and seasoning, chips need to be cooled before packaging. The machine might include a cooling conveyor and a system for packing the finished chips into bags or containers.

-

Control Panel: A semi-automatic machine will have a control panel where operators can adjust settings such as temperature, cutting thickness, and frying time.

-

Safety Features: To ensure safe operation, these machines are equipped with various safety features, including emergency stops and guards to protect operators from moving parts.

Advantages

- Cost-Effective: Semi-automatic machines are generally more affordable than fully automatic systems, making them suitable for small to medium-sized businesses.

- Flexibility: They offer flexibility in production, allowing for manual adjustments to accommodate different types of chips or recipe changes.

- Efficiency: They improve efficiency compared to purely manual methods, reducing labor costs and production time.

High Efficiency, Low Energy Consumption

This semi-automatic chips making machine is engineered to deliver high output while keeping energy usage at a minimum. Its innovative design allows manufacturers to optimize their production efficiency, helping to reduce operational costs. With a processing capacity ranging from 300 to 1000 kg per hour, businesses can scale up production as needed while saving on electricity expenses, making it ideal for growing food processing ventures.

Eco-Friendly and Quiet Operation

The machine operates with low noise and reduced environmental impact, thanks to its eco-friendly features. Built from premium stainless steel, it not only meets food safety standards but also supports sustainable manufacturing practices. Its compact structure ensures that it fits seamlessly into various industrial settings, making it a sound investment for responsible food producers in India.

FAQs of Semi Automatic Chips Making Machine:

Q: How does the semi-automatic chips making machine operate?

A: The machine functions by processing raw materials through cutting, rinsing, and frying stages with minimal manual intervention. Operators simply load the ingredients, and the machine handles multiple steps efficiently, ensuring high output and consistent chip quality.Q: What are the main advantages of using this stainless steel chips making machine?

A: Key benefits include high efficiency, eco-friendly operation, low noise, reduced energy consumption, and easy maintenance due to its durable stainless steel construction. Its compact structure also saves valuable floor space in production facilities.Q: Where can this chips making machine be installed and used?

A: The machine is suitable for a variety of food processing environments, including factories, commercial kitchens, and food production units. Its adaptable design allows it to be integrated into diverse processing lines across India.Q: What is the chips production capacity, and can it be adjusted?

A: This model offers a production capacity of 300 to 1000 kg of chips per hour, supporting both small and large-scale operations. Output can be regulated by adjusting the input and machine settings to match production requirements.Q: When should routine maintenance be carried out for optimal performance?

A: Routine maintenance is recommended at regular intervals, depending on usage intensity. Typically, basic cleaning and inspection after each production cycle, along with scheduled technical servicing, ensure smooth operation and longevity.Q: What energy requirements does the chips making machine have?

A: The machine operates on a 230/440-volt power supply, which is standard in food processing industries. This dual voltage option makes it compatible with different facility setups across India.Q: How does using this machine benefit food processing businesses?

A: Adopting this chips making machine boosts productivity, reduces manual labor, lowers energy costs, and enhances food safety. Its rapid and consistent processing helps businesses meet market demands while maintaining product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Potato Chips Making Machines Category

Rectangular Batch Fryer

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 V

Feature : Other, High Efficiency, Portable

Capacity : 50200 Kg/hr

Automatic : Yes

Circular Batch Fryer

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 V

Feature : Other, Easy to Use, Low Maintenance, High Efficiency

Capacity : 40120 kg/hr (varies by model)

Automatic : Yes

Fully Automatic Potato Chips Plant

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Feature : Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

Capacity : 200 TO 500 Kg/hr

Automatic : Yes

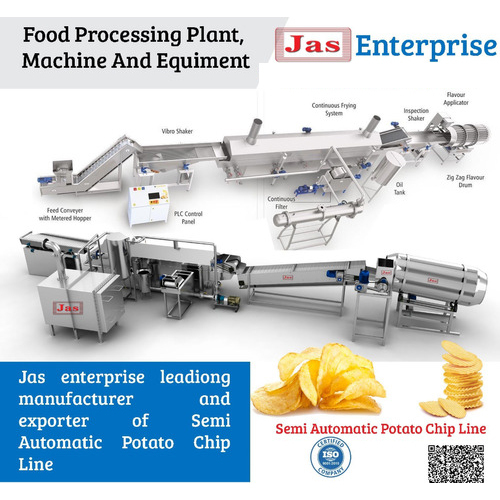

Semi-Automatic Potato Chip Line

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Feature : Lower Energy Consumption, ECO Friendly, Compact Structure, High Efficiency, Low Noice

Capacity : 200 Kg/day

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free