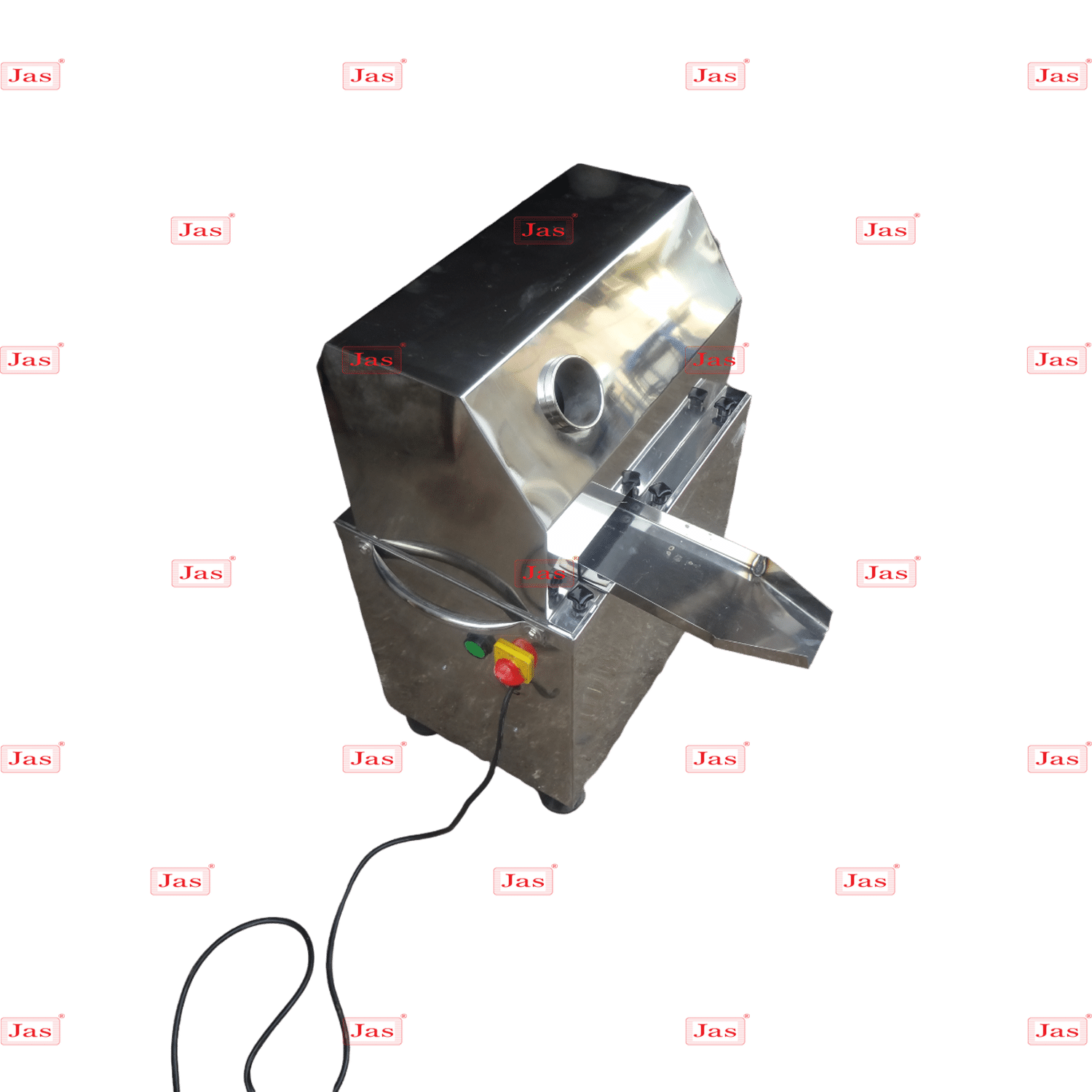

Semi Automatic Sugarcane Juice Machine

Price 35000 INR/ Unit

Semi Automatic Sugarcane Juice Machine Specification

- Power Source

- Electric

- Automation Grade

- Automatic

- General Use

- Industrial

- Material

- Stainless Steel

- Computerized

- No

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Color

- Sliver

- Warranty

- 1 Year

Semi Automatic Sugarcane Juice Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Semi Automatic Sugarcane Juice Machine

-

Feed Mechanism: Usually involves manually feeding sugarcane stalks into the machine.

-

Crushing Mechanism: Automated rollers or gears crush the sugarcane to extract the juice efficiently.

-

Juice Extraction: The machine separates the juice from the crushed cane fibers automatically.

-

Filtration: Some machines include a filtration system to remove any pulp or solids from the extracted juice.

-

Output Collection: Juice is collected in a container or can be dispensed directly into glasses.

-

Cleaning and Maintenance: Typically designed for easy cleaning and maintenance to ensure hygiene and longevity.

-

Power Source: Can be electrically powered, often designed for efficiency and energy conservation.

Advanced Industrial Performance

Engineered for industrial environments, this semi automatic sugarcane juice machine ensures consistent, high-volume output. Its automated system minimizes manual effort while maximizing juice extraction and efficiency, making it an essential addition for businesses seeking reliable and profitable operation.

Built to Last with Stainless Steel

Crafted from high-grade stainless steel, the machine offers resistance to corrosion and wear, ensuring long-term durability. The robust construction, combined with a modern silver finish, promises both hygienic juice production and a professional appearance for your facility.

Eco-Friendly and Energy Efficient

This sugarcane juice machine is designed to conserve energy and operate quietly, fulfilling modern ecological standards. Its compact structure also saves space, making it suitable for various industrial settings where minimizing environmental impact and energy bills is a priority.

FAQs of Semi Automatic Sugarcane Juice Machine:

Q: How does the semi automatic sugarcane juice machine operate?

A: The machine uses automatic pressing and extraction mechanisms powered by electricity. Operators simply load the sugarcane and activate the machine, which automatically crushes and extracts the juice without needing constant manual intervention.Q: What is the recommended usage for this sugarcane juice machine?

A: It is intended for industrial and commercial juice production, ideal for juice factories, processing plants, and large-scale food establishments seeking efficient, high-volume juice extraction.Q: When should maintenance be performed on this machine?

A: Regular cleaning after daily operation and periodic inspection of mechanical parts are advised. The stainless steel design simplifies routine maintenance, and the included 1-year warranty covers manufacturer-related issues.Q: Where is the machine available for purchase in India?

A: The machine is distributed across India, accessible through multiple channels, including distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers.Q: What benefits does this sugarcane juice machine offer for businesses?

A: Users benefit from its eco-friendly features, low energy consumption, minimal noise, high output efficiency, and space-saving compact design, all contributing to cost-effectiveness and operational sustainability.Q: What is the process for installing and setting up the machine?

A: Installation is straightforward: place the machine on a stable surface, connect it to either 230V or 440V power, and follow the provided manual for setup. It is recommended to have a qualified technician assist during installation for optimal operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Beverage Processing Machines Category

Vegetable and Fruit Pulper

Price 5000.00 INR / Unit

Minimum Order Quantity : 01 Unit

Computerized : No

Power : 2 HP

Automatic : Yes

Voltage : 220240 V

Mango Pulper

Minimum Order Quantity : 01 Unit

Computerized : No

Power : 3 HP

Automatic : Yes

Voltage : 220240 V

Apple Juice Plant

Price 44500 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Power : 120 kW

Automatic : Yes

Voltage : 380 V

Sugarcane Juice Extraction Machine

Price 40000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Power : 1 Horsepower (HP)

Automatic : Yes

Voltage : 110415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free