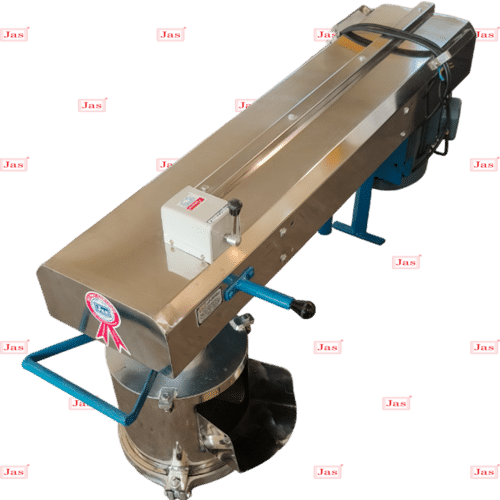

Snacks Processing Machine

Price 25000 INR/ Unit

Snacks Processing Machine Specification

- Capacity

- 25-200 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Snacks Processing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Snacks Processing Machine

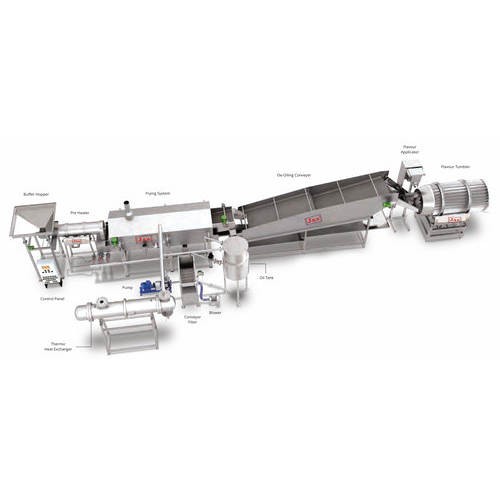

Heres a general overview of how a typical snacks processing machine might work:

-

Ingredient Mixing: Some machines can mix different ingredients according to specific recipes. This might include seasoning, flavorings, and other additives.

-

Cooking or Baking: Depending on the type of snack, the machine might cook or bake the ingredients. For example, for potato chips, the machine might fry the sliced potatoes in oil.

-

Drying: For snacks that require drying, such as dried fruit or beef jerky, machines can provide controlled heat and airflow to remove moisture.

-

Flavoring: After cooking, snacks often need to be coated with flavorings or seasonings. Machines equipped with tumblers or sprayers can evenly apply these coatings.

-

Cooling: Some machines include a cooling section to bring down the temperature of hot snacks to make them crisp and ready for packaging.

-

Packaging: Finally, the processed snacks are usually packaged automatically. This might involve filling bags, sealing them, and labeling them.

The specific features and capabilities of snacks processing machines can vary widely depending on the type of snack being produced and the scale of production. For example, a machine for large-scale industrial use will differ from one designed for small-batch artisanal production.

Eco-Friendly and Sustainable Performance

This snacks processing machine promotes sustainable operations by minimizing energy usage and reducing noise pollution. Its eco-friendly design helps manufacturers and suppliers meet regulatory standards while supporting environmental conservation efforts throughout the product lifecycle.

Compact Yet Powerful Structure

Despite its compact structure, the machine delivers high-efficiency processing suitable for various snack types. The space-saving design allows easy installation in limited areas without compromising output or performance, making it an ideal choice for businesses with restricted floor space.

FAQs of Snacks Processing Machine:

Q: How does the Snacks Processing Machine contribute to eco-friendly manufacturing?

A: The machine uses advanced engineering to lower energy consumption and minimize noise, aligning with eco-friendly manufacturing practices. Its design helps reduce environmental impact while maintaining high efficiency in snack production.Q: What is the processing capacity of this machine and can it be adjusted for different needs?

A: The Snacks Processing Machine offers a flexible capacity range from 25 to 200 kg/hr, suitable for both small and large operations. The capacity can be tailored to specific production requirements, enhancing versatility for various businesses.Q: When should I consider upgrading to an automatic snacks processing machine?

A: You should upgrade to an automatic model when seeking higher productivity, consistent quality, and reduced manual labor. Automation streamlines the production process and improves efficiency, especially for medium to large-scale snack manufacturing.Q: Where is the machine available for purchase in India?

A: The machine can be sourced across India through a wide network of distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers, ensuring accessibility wherever your business is located.Q: What process does the machine follow during snack production?

A: The machine handles all stages automaticallyfrom mixing and shaping to cooking and final packagingensuring uniformity and quality while reducing the need for constant supervision.Q: How does the compact structure benefit business operations?

A: Its compact structure allows for efficient use of workspace, easy installation, and seamless integration into existing production lines, which is particularly advantageous for businesses with limited area.Q: What advantages does lower energy consumption offer snack manufacturers?

A: Lower energy consumption reduces operational costs and helps manufacturers adhere to sustainability goals. It also enhances long-term cost efficiency and environmental responsibility in snack production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Snacks Making Machine Category

Corn Snacks Machine

Price Range 400000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Automatic : Yes

Capacity : 60 TO 550 Kg/hr

Fried Beans, Lentils & Pulses Snacks Production Line

Price Range 375000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Automatic : Yes

Capacity : 500 TO 1000 Kg/hr

Masala Mixing Drum

Price Range 65000.00 - 270000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Electromagnetic (emu)

Automatic : Yes

Capacity : 5 to 160 Kg/Batch Kg/day

Snacks Frying Equipment

Price Range 350000.00 - 700000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Automatic : Yes

Capacity : 50 to 500 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS