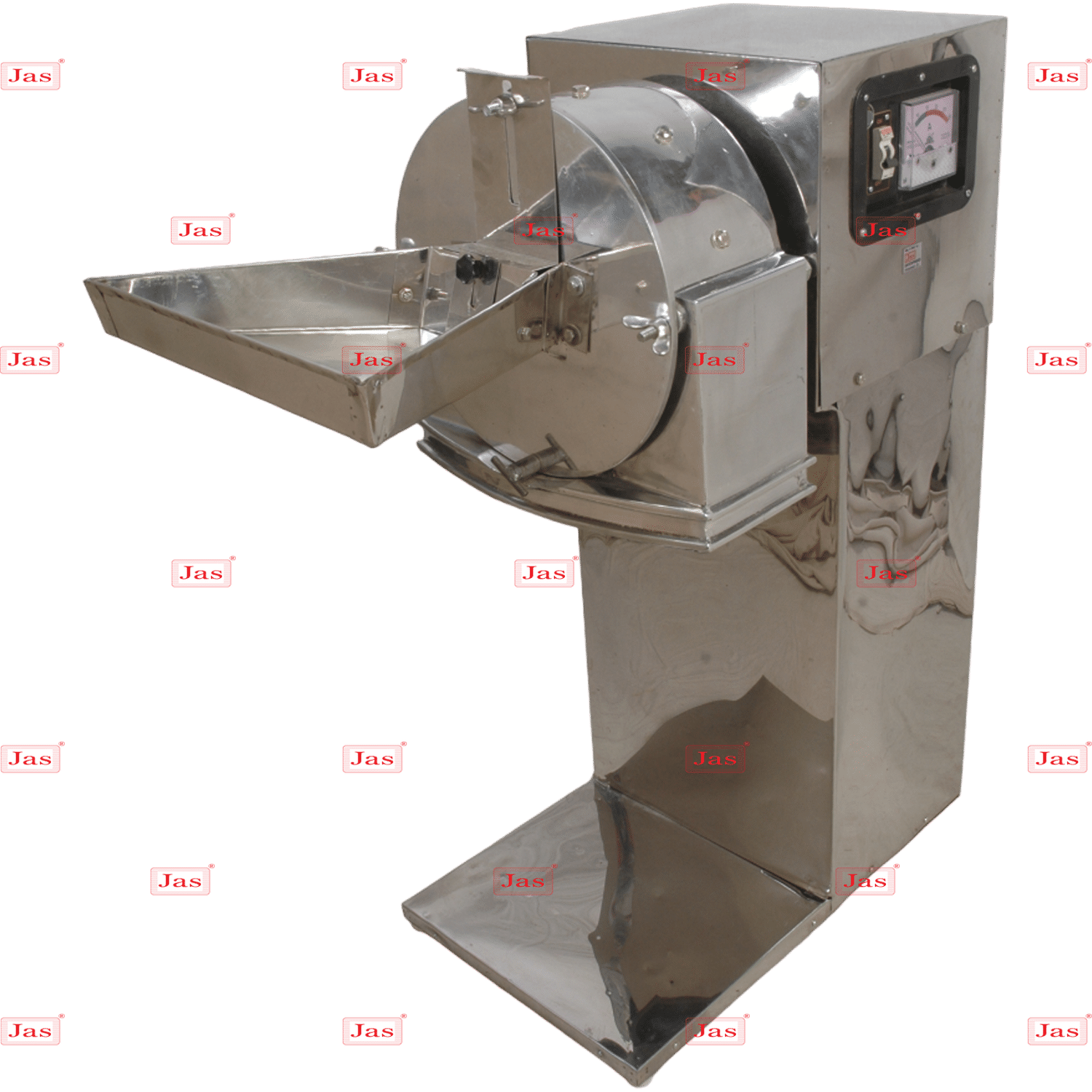

Spice Pulverizer

Price 56000 INR/ Unit

Spice Pulverizer Specification

- Automation Grade

- Automatic

- Power Source

- Electric

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 30-160 Kg/hr

- Automatic

- Yes

- Installation Type

- Free Stand

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Spice Pulverizer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli

- Certifications

- ISO

About Spice Pulverizer

-

Function: Pulverizers use various mechanisms such as blades, hammers, or grinding plates to crush and grind spices. The choice of mechanism can depend on the type of spice and desired fineness.

-

Types:

- Hammer Mills: These use rotating hammers to shred spices into a fine powder. They re versatile and can handle a variety of spice types.

- Blade Grinders: Equipped with sharp blades, these are good for smaller quantities and finer grinding.

- Ball Mills: Utilized for very fine grinding, these use balls to crush spices in a rotating drum.

- Impact Mills: These use high-speed impact to break down spices and are useful for hard or fibrous spices.

-

Capacity: Pulverizers come in various sizes, from small, home-use models to large, industrial machines. Capacity is usually measured in kilograms per hour.

-

Material: The grinding components are often made from stainless steel or other durable materials to handle the abrasive nature of spices and ensure longevity.

-

Cleaning and Maintenance: Regular cleaning is crucial to prevent cross-contamination of flavors and ensure the machine longevity. Some models are designed for easy disassembly and cleaning.

-

Safety: Modern pulverizers come with safety features such as overload protection and safety interlocks to prevent accidents during operation.

Exceptional Performance and Efficiency

Engineered for continuous, automatic operation, this spice pulverizer enhances productivity with its high-capacity range and efficient electric power usage. The robust stainless steel body ensures longevity, while its compact design makes it suitable for space-conscious industrial setups.

Eco-Friendly and User-Focused Design

Designed with the environment and user in mind, the pulverizer maintains low noise levels and consumes less energy, supporting sustainable operations. Its stand-alone installation enables flexible placement across diverse industrial environments, providing seamless integration into existing production lines.

FAQs of Spice Pulverizer:

Q: How does the automatic function of the Spice Pulverizer benefit industrial users?

A: The automatic feature allows for continuous, hands-free operation, increasing efficiency and reducing the need for constant supervision. This leads to consistent processing and improved productivity in industrial settings.Q: What is the recommended installation process for the free-standing Spice Pulverizer?

A: Installation is straightforward; simply position the pulverizer on a level surface and connect it to the 230/440V power supply. No permanent mounting is necessary, making relocation or integration into existing workflows simple.Q: When should you choose this pulverizer over manual or semi-automatic alternatives?

A: This fully automatic machine is ideal when high efficiency, reduced labor, and consistent spice output are top priorities, particularly in medium to large-scale industrial operations demanding reliability and speed.Q: Where can the Spice Pulverizer be used most effectively?

A: Its best suited for industrial environments such as spice manufacturing units, food processing plants, and large-scale kitchens. Its compact, free-standing design accommodates both new and existing production spaces.Q: What capacity range does the pulverizer offer, and how does that impact usage?

A: With a capacity of 30160 kg/hr, it accommodates both smaller batches and substantial spice loads, making it versatile for various production scales without compromising speed or quality.Q: How does the pulverizers eco-friendly design contribute to operational efficiency?

A: Its low energy consumption helps reduce operational costs and environmental impact, while the minimal noise feature creates a safer, more comfortable workplace for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spice Processing Machine Category

Industrial Spice Blender

Price 56000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Warranty : 1 Year

Automatic : Yes

Rice Flour Mill

Price Range 18000.00 - 55000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Warranty : 1 Year Against Manufacturing Defect At Our Site

Automatic : Yes

Haldi Grinding Machine

Price Range - 2000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Warranty : 1 Year Against Manufacturing Defect At Our Site

Automatic : Yes

Red Chilli Grinding Machine

Price 16500.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Warranty : 1 Year Against Manufacturing Defect At Our Site

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free