Spice Roaster Machine

Price 65000 INR/ Piece

Spice Roaster Machine Specification

- Material

- Stainless Steel

- Capacity

- 5 to 160 Kg/hr

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Voltage

- 110-440 Volt (v)

- Power

- 0.5 to 10 Horsepower (HP)

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Spice Roaster Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Pieces Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Himachal Pradesh, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Haryana, Delhi, Gujarat, South India, Madhya Pradesh, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

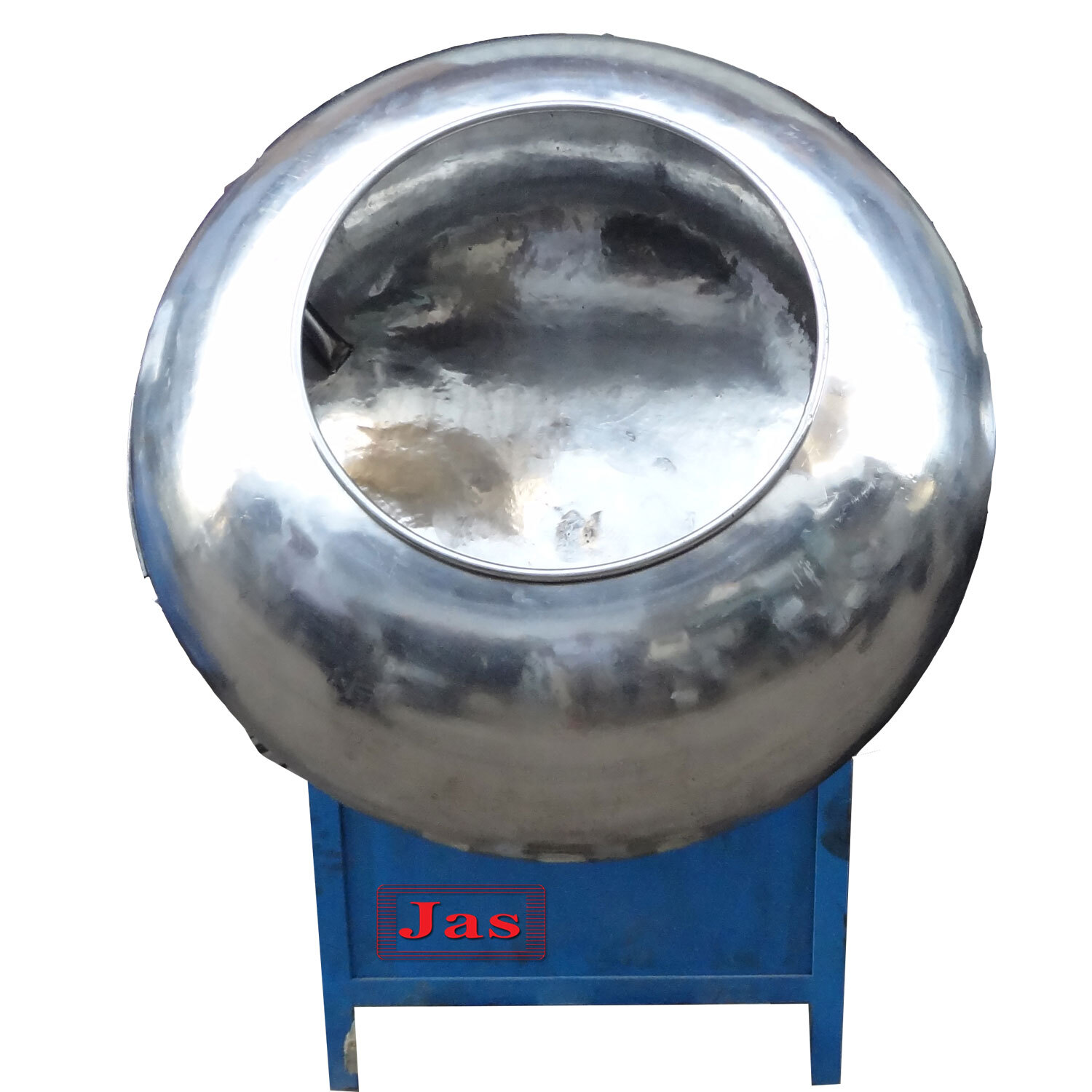

About Spice Roaster Machine

Spice Roaster Machine

Spice Roaster Machine can be used for roasting various types of Spices products like Coriander, Fenugreek seeds, Fennel (Saunf), Bay leaf/Cinnamon leaf (Tej Patta), Cumin (Jeera), Sesame etc. for removing moisture contents from the product and increasing shelflife of Products.

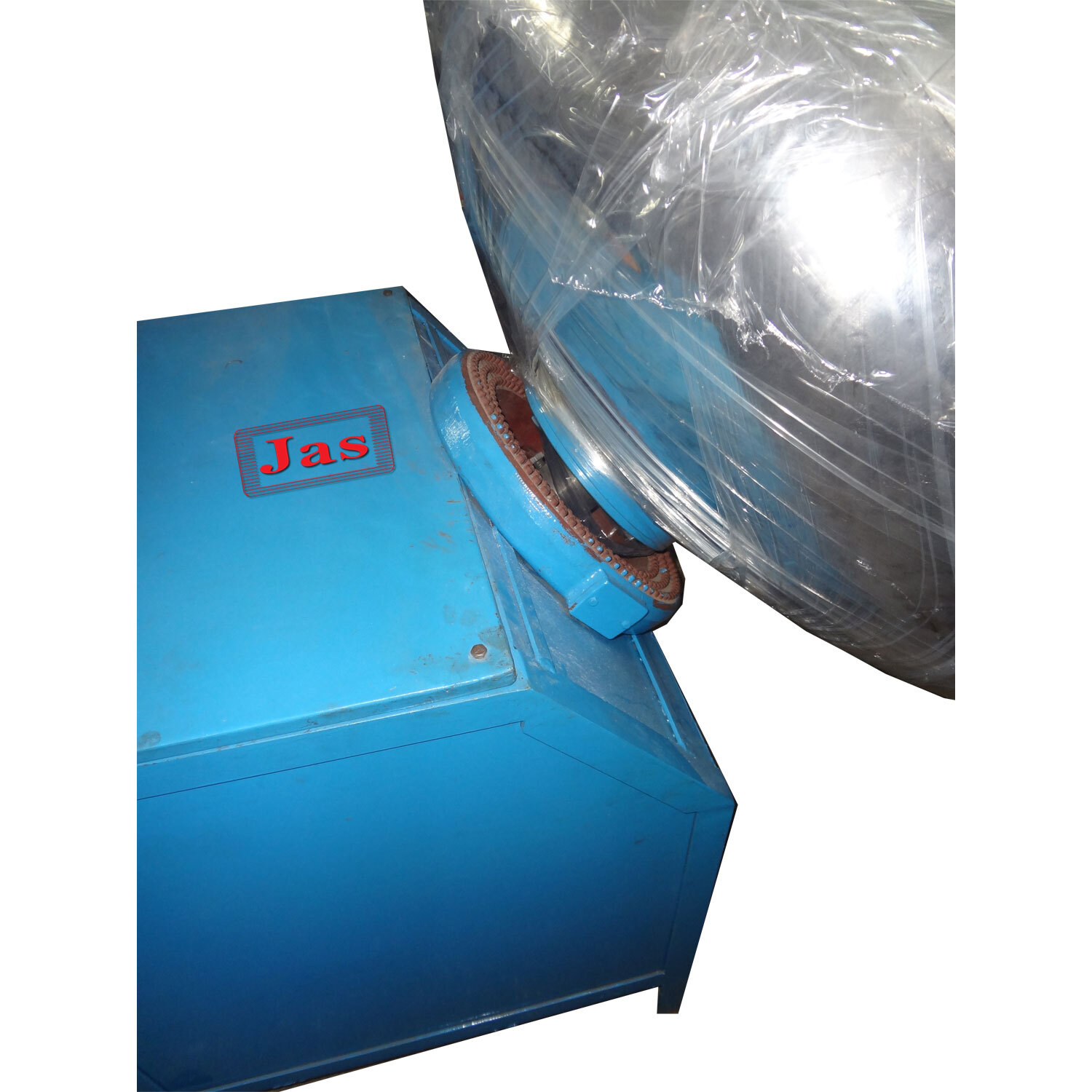

The Heating can be achieved by using LPG or CNG gas. The heating temperature is controlled through Digital Temperature controller.

The heating temperature is controlled through digital temperature controller which can be achieved up to 250 Deg. C.

The Spice Roasters are batch type machines and are supplied as a complete package consisting of process chamber, heating system, Drive unit, pre wired control panel. The Spice Roaster machines are available in sizes ranging from 22 Ltrs. To 5000 Ltrs. Our specially designed spiral ribbons gives the best Roasting results due to Three dimensional action. Thus every particle comes equally in contact with the heating zone and being roasted equally.

Versatile Capacity and Power Range

The Spice Roaster Machine accommodates different production demands, thanks to its adjustable capacity between 5 and 160 kg per hour. It also offers a wide power spectrum from 0.5 to 10 HP, making it suitable for both small and large-scale requirements. Its flexibility ensures smooth adaptation in any commercial setting.

Durable Stainless Steel Construction

Crafted from high-quality stainless steel, this roaster is corrosion-resistant and robust, ensuring long-term performance in rigorous environments. The solid build enhances hygiene, which is essential for food processing, and simplifies cleaning and maintenance processes.

Manual Control for Reliable Operation

The machine features manual control, allowing operators hands-on precision throughout the roasting process. This provides flexibility to fine-tune parameters according to the spice type and production volume, ensuring optimal roasting results without the need for computerized systems.

FAQs of Spice Roaster Machine:

Q: How does the manual control system work on the Spice Roaster Machine?

A: The manual control system allows operators to adjust roasting parameters, such as temperature and drum rotation, using physical knobs or levers. This provides direct hands-on management of the process, enabling precise control tailored to the specific spice and batch size.Q: What are the major benefits of using a stainless steel spice roaster?

A: Stainless steel offers outstanding durability and resistance to corrosion, which is crucial for food safety. Additionally, it is easy to clean and maintain, promoting hygienic processing and long machine life.Q: When is the 1-year warranty applicable, and what does it cover?

A: The machine includes a 1-year warranty against manufacturing defects, applicable from the date of purchase. This warranty covers any material or workmanship issues that arise during normal use, provided the machine is operated at our site according to recommended guidelines.Q: Where can this Spice Roaster Machine be supplied or exported from in India?

A: As a manufacturer, distributor, exporter, supplier, trader, wholesaler, and retailer, we offer the Spice Roaster Machine throughout India. We also handle export orders for international clients from our Indian manufacturing base.Q: What is the roasting process on this machine, and how is it managed?

A: The process involves loading the machine, adjusting controls manually, and allowing the spices to roast through consistent heat and drum movement. Operators monitor and adjust settings as needed to achieve the desired roast, then unload the finished product once complete.Q: How does the capacity range benefit different user groups?

A: With a capacity ranging from 5 to 160 kg/hr, the roaster caters to small-scale producers as well as large commercial operations. Businesses can select the ideal capacity to match their batch sizes, enhancing efficiency and scalability.Q: What types of power supply is this Spice Roaster compatible with?

A: The Spice Roaster Machine is designed to operate within a voltage range of 110 to 440 Volts and power settings from 0.5 to 10 HP, ensuring compatibility with various industrial power sources and allowing flexibility for different operational setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spice Processing Machine Category

Masala Roasting Machine

Price 70000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 110440 Volt (v)

Power : 0.5 to 10 Horsepower (HP)

Warranty : 1 Year Against Manufacturing Defect At Our Site

Rice Flour Mill

Price Range 18000.00 - 55000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Power : 1.5 to 2 Horsepower (HP)

Warranty : 1 Year Against Manufacturing Defect At Our Site

Haldi Grinding Machine

Price Range - 2000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Power : 2 to 200 Horsepower (HP)

Warranty : 1 Year Against Manufacturing Defect At Our Site

Hammer Mill Pulverizer

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110440 Volt (v)

Power : 20100 Horsepower (HP)

Warranty : 1 Year Against Manufacturing Defect At Our Site

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free