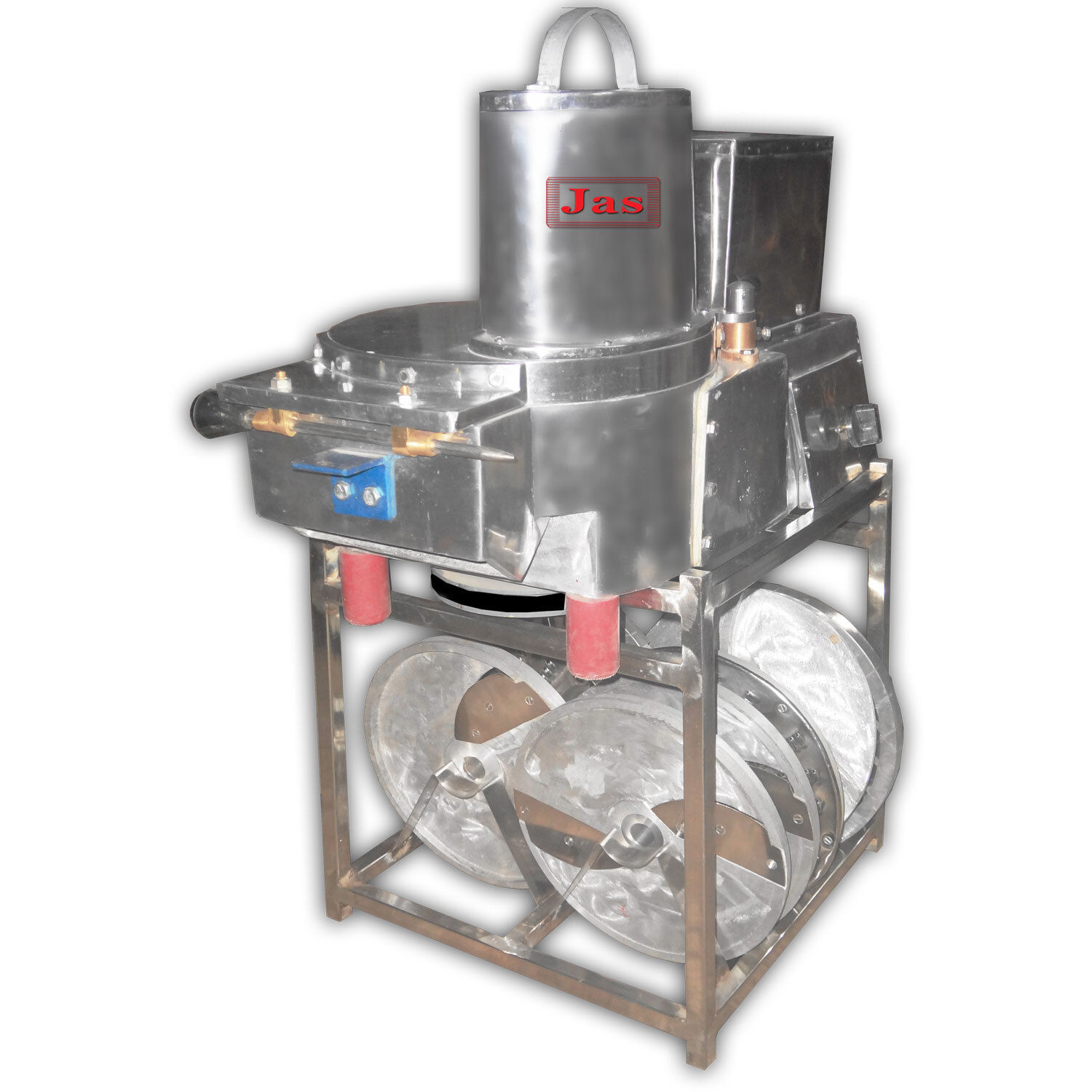

Vegetable Cutter

Price 10000 INR/ Unit

MOQ : 1 Unit

Vegetable Cutter Specification

- Application

- Commercial Kitchen, Restaurants, Hotels

- Material Grade

- 304 Food Grade Stainless Steel

- Control System

- Manual Operation

- Power Source

- Hand Operated

- Installation Type

- Table Top

- Features

- Durable, Corrosion Resistant, Easy to Clean

- Processing Technology

- Cutting/Chopping

- Material

- Stainless Steel

- Automatic Grade

- Manual

- Capacity

- 100 to 125 Kg/hr

- Temperature Range

- Ambient

- Shape

- Rectangular

- Usage

- Vegetable Slicing/Chopping

- Size

- Standard

- Dimension (L*W*H)

- 510 X 305 X 435 Millimeter (mm)

- Weight

- Approx. 20 Kg

- Color

- Silver

- Noise Level

- Silent Operation

- Portability

- Portable Design

- Safety Features

- Anti-Slip Base, Safety Handle

- Equipment Type

- Vegetable Cutter

- Finishing

- Polished

- Maintenance

- Low Maintenance

- Cutting Blades

- Interchangeable Stainless Steel Blades

Vegetable Cutter Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Sikkim, Meghalaya, , Lakshadweep, Gujarat, South India, North India, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Chandigarh, Daman and Diu, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Tamil Nadu, Telangana, Tripura, Uttarakhand, West Bengal, Delhi, Uttar Pradesh, Bihar, Central India, West India, Chhattisgarh, All India

About Vegetable Cutter

Utilizing the knowledge and experience, we have been committed to manufacture and export robustly built Vegetable Cutter. This cutter is manufactured using high grade stainless steel that is obtained from certified vendors of the market. Our offered cutter is made available in different models and specifications that clients can avail as per their needs. This cutter is suitable for cutting of various kinds of vegetables, cheese and fruits. We are offering this Vegetable Cutter at market leading prices.

Various characteristics:

- Easy to clean

- Rust proof

- Easy usage

- Longer service life

Other details:

Vegetable Cutter can cuts various leafy and salad vegetables, fruits, flowers and flower buds, pod vegetables (legumes), bulb and stem vegetables, root and tuberous vegetables, sea vegetables like green onion, garlic sprout, leek, celery, cabbage, apples, bananas, beetroot, cabbage, carrot, celery, cucumbers, fennel, kiwis, kohlrabi, leek, mushroom, onions, parsley, peer, pepper, pickled cucumbers, potatoes, radish, tomatoes, zucchini and many more. Various roots vegetables: carrot, potato, sweet potato, bamboo shoot, onion, eggplant, cucumber. Commercial vegetable slicer is suitable to cut all vegetables, fruits in different shapes like slices, dices, grates, julienne slicer, granulates, and sheared quickly and accurately by interchangeable blades of Vegetable Cutters without altering the natural qualities of the fruits, vegetables or any food products.Engineered for Durability and Hygiene

Manufactured from high-quality 304 food-grade stainless steel, this vegetable cutter guarantees robust durability and resistance to corrosion. The polished surface not only enhances its aesthetic appeal but also simplifies cleaning, ensuring hygiene standards are consistently maintained in demanding commercial environments.

Flexible and Efficient Cutting Solutions

Equipped with interchangeable stainless steel blades, this cutter offers versatile chopping and slicing options. Its manual, hand-operated mechanism enables precise control while remaining silent, making it suitable for noise-sensitive areas. With an output of 100 to 125 kg/hr, it effortlessly meets the high-volume demands of restaurants and hotels.

Safety and Convenience First

Designed with an anti-slip base and safety handle, this cutter prioritizes operator safety during intensive use. Its portable, table-top configuration allows for easy positioning and storage in various kitchen layouts. The low-maintenance design means less downtime and maximized productivity for busy culinary settings.

FAQs of Vegetable Cutter:

Q: How does the interchangeable blade system work on this vegetable cutter?

A: The vegetable cutter features a set of stainless steel blades that can be quickly swapped out, allowing you to easily alternate between different cutting and chopping styles based on your kitchens requirements.Q: What safety features are included to protect users during operation?

A: This cutter includes an anti-slip base to prevent movement during use and a dedicated safety handle for secure hand placement, reducing the risk of accidental contact with the blades.Q: When is this vegetable cutter most beneficial for commercial use?

A: It is particularly advantageous during peak food preparation times in commercial kitchens, restaurants, and hotels, enabling rapid processing of large volumes of vegetables without generating noise or requiring electrical power.Q: Where can the vegetable cutter be installed or used within a professional kitchen?

A: Designed as a portable table-top unit, this cutter can be positioned on any flat, sturdy surface, making it adaptable to a variety of kitchen spaces and even suitable for off-site catering events.Q: What is the maintenance process for this manual vegetable cutter?

A: Thanks to its polished stainless steel construction and simple manual design, cleaning and maintaining the cutter involves rinsing the blades and main unit with water, ensuring both hygiene and long-term performance with minimal effort.Q: How does the manual operation benefit users compared to powered alternatives?

A: Manual operation offers silent performance, energy savings, and precise control over the cutting process, making it ideal for noise-sensitive areas and locations without reliable electricity.Q: What are the main advantages of using this cutter in a commercial environment?

A: Key benefits include high cutting capacity, durable construction, corrosion resistance, easy cleaning, enhanced safety features, and exceptional portability, all tailored to streamline vegetable preparation for busy culinary teams.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Commercial Kitchen Equipments Category

Food Steamer

Price Range 5000.00 - 20000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic Grade : Other, Automatic

Power : Other, 2.6 kW

Maida Mixer Machine

Price 8000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Automatic Grade : Other, Automatic

Power : Other, 2 HP

Finger Chips Machine

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Automatic Grade : Manual

Power : Electric

Electric Idli Steamer

Price Range 12000.00 - 85000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic Grade : Semi Automatic

Power : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS