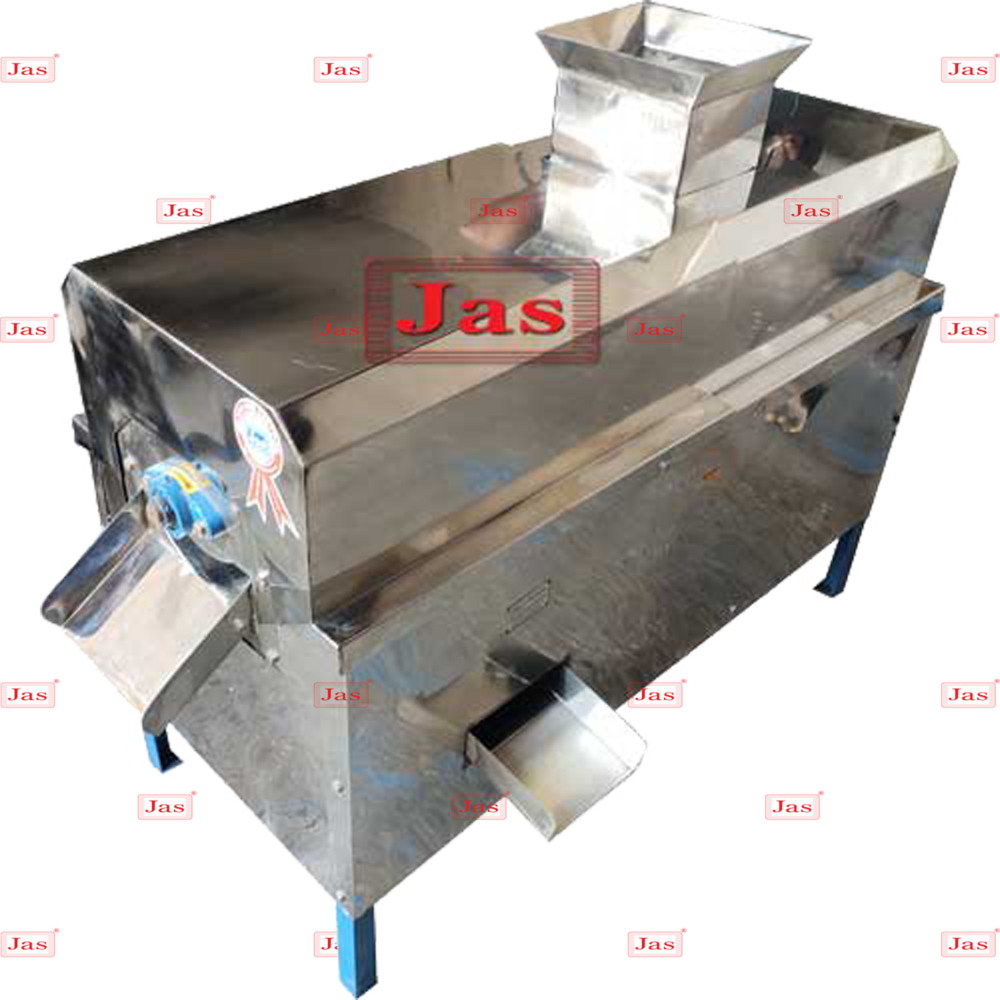

Amla Processing Machine

Price 44500 INR/ Unit

Amla Processing Machine Specification

- Type

- Amla Processing Machine

- Material

- Stainless Steel

- Capacity

- 200-500 kg/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Voltage

- 230-440 Volt (v)

- Frequency (MHz)

- 50-60 Hertz (HZ)

- Preheating Plate Size

- 450 x 200 mm

- Cutting Thickness

- 1-10 mm (Adjustable)

- Belt Diameter

- 300 mm

- Size

- Standard / Custom

- Width

- 650 mm

- Weight

- 120 kg

- Dimension (L*W*H)

- 1500 x 650 x 1200 mm

- Body Finish

- Matt / Mirror Polish

- Production Efficiency

- High Output, Minimal Wastage

- Motor Type

- Induction Motor

- Safety Features

- Emergency Stop Switch, Covered Blades

- Suitable For

- Commercial Food Processing Units, Small Scale Industries

- Power Requirement

- 2 HP

- Noise Level

- Low

- Maintenance

- Easy to Clean & Maintain

- Drive Type

- Belt & Gear

- Application

- Amla Cutting, Seed Removal, Pulp Extraction

Amla Processing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO 9001

About Amla Processing Machine

Amla processing machines are specialized equipment designed to handle the various stages of processing Indian gooseberries (amla) into different products. These machines are used in industries like food processing, herbal medicine, and cosmetics. Heres a detailed description of the different types of amla processing machines:

1. Amla Washing Machine- Function: Cleans amla by removing dirt, dust, and other impurities.

- Features:

- Made of stainless steel for durability and hygiene.

- Equipped with a water spray system and brushes for thorough cleaning.

- Conveyor system for continuous operation.

- Function: Cuts amla into halves or desired sizes for further processing.

- Features:

- Stainless steel construction.

- High-speed rotating blades for efficient cutting.

- Adjustable settings for different cut sizes.

- Function: Removes seeds from amla pulp.

- Features:

- Stainless steel body.

- Precision engineering to ensure minimal wastage.

- Easy to clean and maintain.

- Function: Extracts pulp from amla for making juices, jams, and other products.

- Features:

- High extraction efficiency.

- Continuous pulping mechanism.

- Stainless steel construction for hygiene.

- Function: Dries amla to make powder or preserve it.

- Features:

- Temperature control for uniform drying.

- Multiple trays or conveyor belts for large batch processing.

- Energy-efficient design.

- Function: Converts dried amla into fine powder.

- Features:

- Stainless steel body.

- High-speed grinding mechanism.

- Dust-free operation.

- Function: Extracts juice from amla pulp.

- Features:

- Stainless steel construction.

- High yield extraction.

- Easy to clean and maintain.

Efficient Amla Processing for Enhanced Productivity

This machine streamlines the labor-intensive processes of amla cutting, seed removal, and pulp extraction. With a production capacity of 200500 kg/hr and adjustable cutting thickness, it delivers consistent, high-quality output. Its semi-automatic operation reduces manual effort and increases throughput, making it an invaluable asset for food processing professionals seeking productivity gains and minimal ingredient wastage.

Durable Design with Safety and Hygiene in Mind

Constructed with food-grade stainless steel and available in both matt and mirror finishes, this equipment ensures hygiene and corrosion resistance. Safety is prioritized through features such as an emergency stop switch and fully covered blades, minimizing operational risks. Its easy-to-clean components simplify maintenance, helping businesses maintain high sanitation standards effortlessly.

Versatile Application Tailored for Diverse Setups

Whether for commercial food processing plants or small-scale industries, the Amla Processing Machine offers flexibility with standard and custom dimensions, accommodating varied production needs. Operating at 230440 volts and 5060 Hz, its adaptable power requirements make it suitable for different electrical environments. Its low-noise performance further supports seamless integration in any facility.

FAQs of Amla Processing Machine:

Q: How does the Amla Processing Machine improve production efficiency?

A: The machine combines amla cutting, seed removal, and pulp extraction into one streamlined process, achieving a high output rate of 200500 kg/hr with minimal wastage. Its semi-automatic operation ensures consistent performance while reducing manual intervention.Q: What safety features are included in this Amla Processing Machine?

A: Safety is enhanced through an emergency stop switch and covered blades, which protect operators during use. These features ensure compliance with industrial safety standards and minimize the risk of accidents during operation.Q: When is maintenance required, and how easy is it to clean?

A: The machine is designed for easy, regular cleaning, with smooth stainless steel surfaces that facilitate quick sanitation. Routine cleaning after each use is recommended to maintain optimal performance and hygiene.Q: Where can this machine be used effectively?

A: It is suitable for commercial food processing units, small-scale industries, and other businesses handling significant volumes of amla. Its adaptability in size and power requirements makes it fit for a variety of industrial settings in India and beyond.Q: What benefits does the adjustable cutting thickness offer?

A: The adjustable cutting thickness (110 mm) allows users to customize the processing according to product specifications or consumer preferences, making the machine versatile for different amla-based applications.Q: How do I operate the machine safely and efficiently?

A: To operate safely, always ensure the safety covers are secured and engage the emergency stop switch in case of any irregularity. Regularly inspect the belt and gear drive, and follow manufacturer guidelines for operating the induction motor within specified voltage and frequency ranges.Q: What is the material used for construction and why is it important?

A: The machine is built from high-grade stainless steel, providing excellent resistance to corrosion and ensuring food safety. This material choice also makes the device durable and suitable for long-term use in rigorous processing environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fruit Pulping Machine Category

Tamarind Seed Removing Machine

Price 33000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 5060 Hertz (HZ)

Voltage : 220/440 Volt (v)

Warranty : One year against manufacturing defect at our side

Automatic Grade : SemiAutomatic

Amla Seed Remover

Price 33000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 5060 Hertz (HZ)

Voltage : 230/440 Volt (v)

Warranty : One year against manufacturing defect at our side

Automatic Grade : SemiAutomatic

Date Seeds Removing Machine

Price 33000 INR / Unit

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 5060 Hertz (HZ)

Voltage : 230/440 Volt (v)

Warranty : One year against manufacturing defect at our side

Automatic Grade : SemiAutomatic

Kharak seed removal machine

Price 33000 INR / Piece

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 5060 Hertz (HZ)

Voltage : 230/440 Volt (v)

Warranty : One year against manufacturing defect at our side

Automatic Grade : SemiAutomatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS