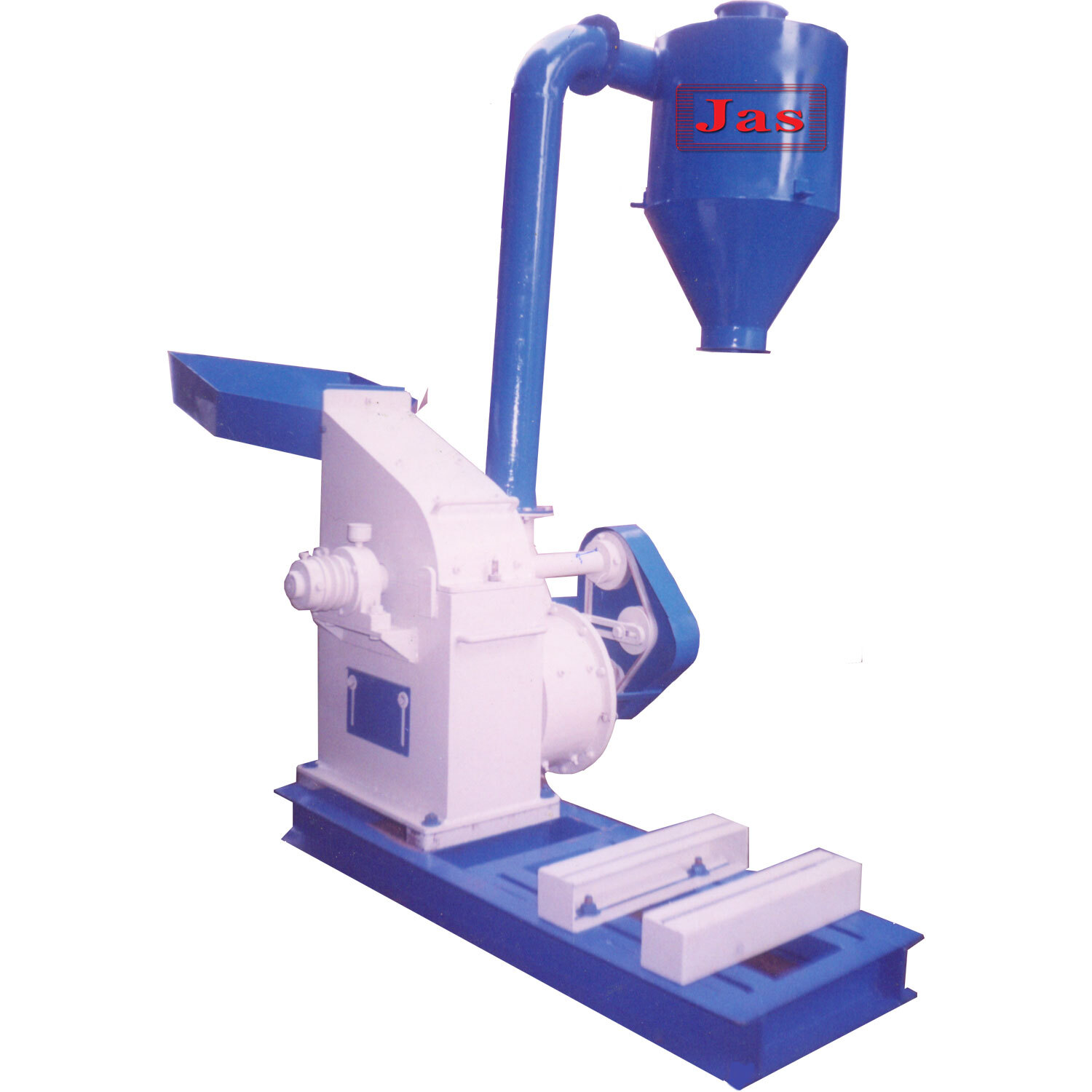

Auto Suction Hammer Mill

Auto Suction Hammer Mill Specification

- Material

- Stainless Steel

- Weight (kg)

- 65 Kilograms (kg)

- Automatic

- Yes

- Power

- 3000 to 7000 Watt (w)

- Voltage

- 110 to 415 Volt (v)

- Color

- Blue

Auto Suction Hammer Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- Week

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

About Auto Suction Hammer Mill

- High tensile strength

- Superior finish

- Easy installation

- Low maintenance cost

- Less operating cost due to automatic rotary tank feeding.

- Easy to operate and collect ground material without air pressure, due to specialized cyclone and dust collector.

- Due to availability of beater carbides in automatic suction hammer mills, it is not necessary to change beater frequently, which also ensures that production is not affected.

- Separate motor for hammer mill, blower, and rotary feeder, thus RPM of blower or hammer mill and ampere of motors does not fluctuate, hence increasing the working capacity of machine.

Product details

|

Country of Origin |

Made in India |

|

Automation Grade |

Automatic |

|

Phase |

Three Phase |

|

Material |

Steel |

|

Brand |

Jas |

|

Speed |

3500 rpm |

|

Capacity |

280 kg per hr |

|

Power |

7.5 HP |

High-Efficiency Grinding

Engineered for optimum performance, the Auto Suction Hammer Mill delivers quick and consistent particle size reduction. Its automatic operation and high-powered motor minimize manual involvement while boosting overall productivity. The stainless steel construction ensures long-lasting durability, even with heavy-duty use.

Versatile Applications

This hammer mill caters to a wide range of industries including agriculture, food processing, and pharmaceuticals. Its versatile voltage compatibility and robust power output make it adaptable for various operational environments, providing seamless integration with other machinery.

Reliable Distribution Network

Supplied, exported, and retailed by established distributors across India, the Auto Suction Hammer Mill is readily available to meet the demands of both large-scale industries and small businesses. Comprehensive support and after-sales services are offered by trusted partners nationwide.

FAQs of Auto Suction Hammer Mill:

Q: How does the Auto Suction Hammer Mill work?

A: The Auto Suction Hammer Mill automatically feeds raw materials into a grinding chamber where rotating hammers pulverize them into fine particles. The suction system efficiently transfers processed material for easy collection and further use.Q: What materials can be processed with this hammer mill?

A: This stainless steel hammer mill is suitable for grinding grains, spices, herbs, and other agricultural products, as well as materials used in food processing and pharmaceutical industries.Q: When should routine maintenance be performed on the hammer mill?

A: Routine maintenance should be conducted after every operating cycle or as recommended in the user manual. Regular checks ensure optimal performance, prevent downtime, and extend the lifespan of the machine.Q: Where is the Auto Suction Hammer Mill available in India?

A: The hammer mill can be purchased from authorized distributors, suppliers, exporters, manufacturers, and retailers throughout India. Availability ensures timely delivery and support for various business needs.Q: What is the usage process for this machine?

A: Place the material in the feed hopper, set the required parameters, and start the machine. It will automatically grind the input and collect the finished product in a designated container, thanks to the integrated suction system.Q: What are the main benefits of using this hammer mill?

A: Key benefits include automatic operation, consistent particle size, robust stainless steel construction, compatibility with a wide voltage range, and reliable availability from multiple sources across India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding, crushing and Pulverizing Machine Category

Maize Grinding Hammer Mill

Price 15000.00-650000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 20 to 2200 Kg/hr

Corn Grinding Machine

Price 18000.00 INR / Piece

Minimum Order Quantity : 1000 Units

Voltage : 230/440 Volt (v)

Capacity : 202200 Kg/hr

Power : 2125 Horsepower (HP)

Double Stage Pulverizer

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 415 Volt (v)

Capacity : 3035 Kg/hr

Power : 3000 to 7000 Watt (w)

Flour Mill Machinery and Accessories

Price Range 18500.00 - 125000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 Volt (v)

Capacity : 3035 Kg/hr

Power : 1500 Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free