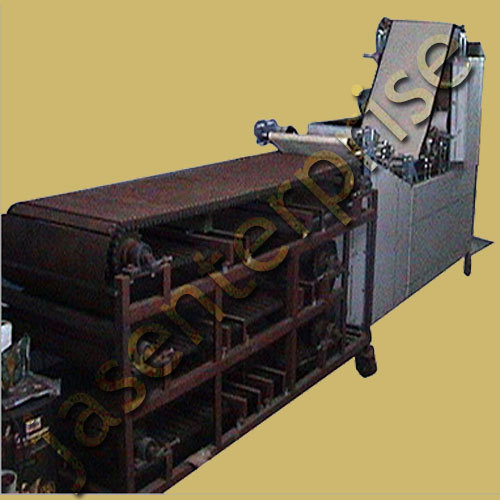

Automatic Chapati Making Machines

Price 5000 INR/ Unit

MOQ : 1 Unit

Automatic Chapati Making Machines Specification

- Material

- Stainless Steel, Aluminum

- Type

- Roti Making Machine

- Capacity

- 3000.0 Kg/hr

- Product Thickness

- 2.5, 2, 1, 1.5 Millimeter (mm)

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

Automatic Chapati Making Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Months

About Automatic Chapati Making Machines

Our company has designed & developed a very simple, compact and Fully Automatic Chapati Making Machine. This machine is capable to meet the demand and quality. We guarantee one of the most hygienic way of making home like chapatis. These machines are electrically operated and are very simple to operateEngineered for High-Volume Chapati Production

Designed with both efficiency and scalability in mind, this chapati making machine offers an unmatched capacity of 3000 kg/hr, streamlining processes for high-demand environments. Stainless steel and aluminum components ensure longevity even with extensive daily use.

Varied Thickness for Culinary Flexibility

The machines adjustable thickness settings, ranging from 1 mm up to 2.5 mm, allow users to craft chapatis suited to diverse preferences and applications from soft, thin rotis to thicker, more robust variants.

Automatic Operation for Labor Savings

Automation is at the heart of this system, enabling users to produce consistent rectangular chapatis at a rapid pace without manual effort. Its user-friendly operation is particularly beneficial for commercial kitchens, reducing dependency on skilled labor.

FAQs of Automatic Chapati Making Machines:

Q: How does the automatic chapati making machine simplify the chapati-making process?

A: The machine automates dough pressing and shaping, minimizing manual labor and ensuring consistent thickness and shape. As a result, it speeds up production and delivers uniform chapatis for large-scale food service operations.Q: What types of facilities most benefit from this machines high capacity?

A: Large commercial kitchens, catering services, canteens, hotels, and food manufacturing units in India benefit most, as the 3000 kg/hr capacity meets the requirements for mass production efficiently.Q: When is the ideal time to invest in an automatic roti making machine for your business?

A: Businesses experiencing increased demand or aiming to expand production capabilities should consider investing in this machine to enhance productivity and reduce reliance on manual labor.Q: Where is the machine typically installed for optimal efficiency?

A: Installation is best in spacious, well-ventilated commercial kitchens, food processing units, or centralized production facilities where operational flow can be maintained seamlessly.Q: What is the process for adjusting the chapati thickness on the machine?

A: Users can easily select desired thickness between 1 mm and 2.5 mm using the machines built-in adjustment settings, allowing seamless customization according to specific menu requirements.Q: How is this chapati maker advantageous in terms of hygiene and durability?

A: Made from stainless steel and aluminum, the machine resists corrosion and is easy to clean, supporting stringent hygiene standards required in food manufacturing and commercial services.Q: What shapes of chapati does the machine produce, and can it be customized?

A: Currently, the machine is designed to produce rectangular chapatis. While standard models focus on this shape, some manufacturers may offer customized solutions based on specific client needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Chapati Making Machines Category

Roti Chapati Machines

Price 50000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 215 Volt (v)

Capacity : >900 Kg/hr

Material : Stainless Steel, Aluminum

Automatic : Yes

Phulka Roti Making Machine

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 440 Volt (v)

Capacity : 600 to 3000 Roti/Hr Pcs/min

Automatic : Yes

Roti Maker Machines

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 440 Volt (v)

Capacity : 600 to 3000 Roti/Hr Pcs/min

Material : Stainless Steel

Automatic : Yes

Stainless Steel Chapati Puffer

Minimum Order Quantity : 1 Unit

Voltage : 110 440 Volt (v)

Capacity : 600 to 2000 chapati/Hr Pcs/min

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free