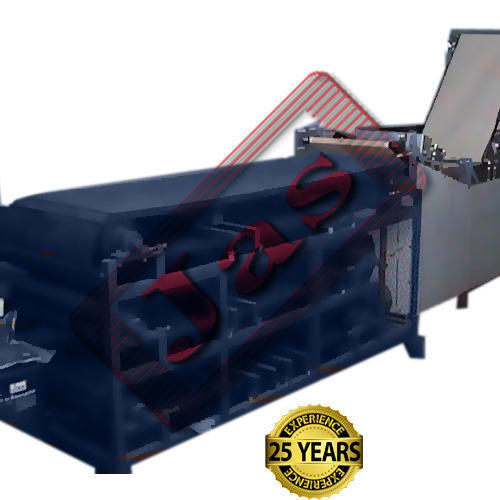

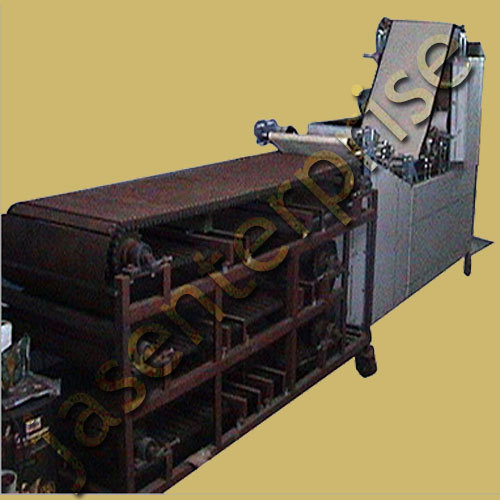

Phulka Roti Making Machine

Price 10000.00 INR/ Unit

Phulka Roti Making Machine Specification

- Type

- Roti Making Machine

- Capacity

- 600 to 3000 Roti/Hr Pcs/min

- Computerized

- Yes

- Automatic

- Yes

- Voltage

- 110 - 440 Volt (v)

- Feature

- High Quality, Non Stick Coating, Environment Friendly, Low Noise, High Efficiency, Multi Functional

Phulka Roti Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Eastern Europe, Middle East, South America, Western Europe, Central America, North America, Australia, Africa

- Main Domestic Market

- Dadra and Nagar Haveli, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Nagaland, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Delhi, Gujarat, Telangana, Central India, Odisha, Jharkhand, West India, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Phulka Roti Making Machine

Phulka Roti Making Machine

In the series of our range of products, we are engaged in manufacturing, supplying, and exporting an extensive range of Automatic Phulka Roti Making Machine in Ahmedabad, Gujarat, India. The Automatic Phulka Roti Making Machine is manufactured from the finest grade of raw materials provide them at very nominal prices.

Advanced Automation and Computerized Control

With this roti making machine, advanced computerized controls manage the roti preparation process. Its automatic features allow operators to produce consistent results with minimal supervision, enhancing productivity and ensuring uniform roti quality across batches.

Environmentally Conscious and Quiet Operation

The Phulka Roti Making Machine incorporates technology that reduces noise and utilizes eco-friendly practices. This ensures your kitchen remains comfortable and sustainable, supporting both culinary goals and environmental responsibility.

FAQs of Phulka Roti Making Machine:

Q: How does the Phulka Roti Making Machine ensure high-quality rotis?

A: The machine utilizes computerized controls and a non-stick coating that ensures consistent thickness, texture, and even cooking, resulting in high-quality rotis every time.Q: What is the capacity range of this roti making machine?

A: Depending on your requirements, the machine can produce between 600 to 3000 rotis per hour, making it suitable for small eateries and large commercial kitchens alike.Q: When should I consider using this machine in my business?

A: If you need to scale up production, reduce manual labor, or maintain consistency in rotis, this machine is ideal for food businesses, hotels, caterers, and institutions.Q: Where is the Phulka Roti Making Machine available for purchase in India?

A: You can purchase the machine from distributors, exporters, manufacturers, retailers, suppliers, traders, or wholesalers across India.Q: What is the process for operating the roti making machine?

A: Simply feed the prepared dough into the machine, set the desired parameters on the computerized panel, and the machine automatically handles pressing, cooking, and ejecting the finished rotis.Q: How does the non-stick coating benefit usage and maintenance?

A: The non-stick coating prevents dough from adhering to the machines surface, making cleaning simpler and ensuring rotis do not tear or stick during production.Q: What are the primary benefits of investing in this roti making machine?

A: Benefits include high efficiency, multi-functional capabilities, reduced operational noise, energy savings, consistent quality, and eco-friendly performance, helping businesses streamline processes and lower labor costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chapati Making Machines Category

Dough Kneader

Price 6000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 5 to 50 Kg/hr

Automatic : Yes

Material : Stainless Steel

Computerized : No

Fully Automatic Chapati Making Machine

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 600 to 3000 Chapati/Hr Pcs/min

Automatic : Yes

Material : Stainless Steel

Computerized : Yes

Chapati Making Machine

Minimum Order Quantity : 1 Unit

Capacity : 800 3000 chapati/hr T/hr

Automatic : Yes

Material : Stainless Steel

Computerized : Yes

Automatic Chapati Making Machines

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 3000.0 Kg/hr

Automatic : Yes

Material : Stainless Steel, Aluminum

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free