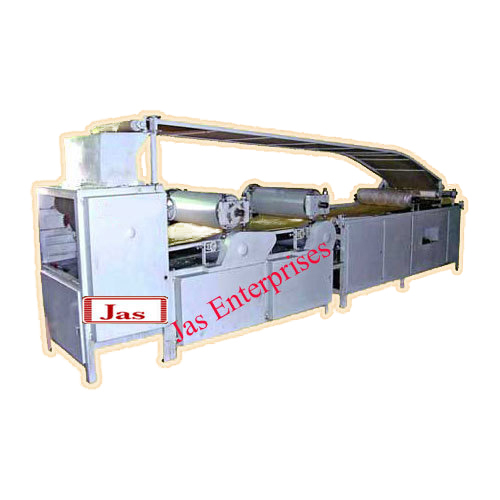

Automatic Papad Making Machine

Price 150000.00 INR/ Unit

MOQ : 1 Unit

Automatic Papad Making Machine Specification

- Material

- Stainless Steel

- Type

- Snacks Extruder

- Capacity

- 5 to 15 Kg/hr

- Computerized

- No

- Automatic

- Yes

- Voltage

- 221 Volt (v)

Automatic Papad Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 15 Days

About Automatic Papad Making Machine

Our company is among the top most organization involved in manufacturing and exporting quality assured Automatic Papad Making Machine. Our offered machine is manufactured using high grade stainless steel and other components that are procured from certified vendors of the market. In order to suit the demands of clients, this machine is made available in different models and specifications. This Automatic Papad Making Machine is stringently checked on various parameters like superior finish and high material strength.

Various characteristics:

- Longer service life

- Sturdy construction

- Perfect finish

- High performance

Other details:

Papad Making Machine

A dough sheeter consisting of a heavy- duty frame with gauging rollers driven by a motor with gearbox arrangement would be provided. The hopper would be of stainless steel with proper taper. The dough is smoothly formed from the hopper in the form of a sheet and fed to the gauging rollers. The distance between the gauging rollers would be adjustable and this would depend on the desired thickness of the papad, mathiya, cholafali. The rollers would be PVC coated (food-grade material). There would be an intermediate endless food grade conveyor to feed the dough sheet to the cutting plant. The conveyor belt would be of food-grade material. A rotary cutting unit would be fitted on a roller for smooth and accurate cutting of Papad as per the desired sizes.

Efficient Papad Production

Experience seamless papad making with our automatic machine, designed to streamline your snack production process. The machines 5 to 15 kg/hr capacity gives small to medium-sized businesses a competitive edge, saving both time and labor. Built with premium stainless steel, it assures hygiene and easy maintenance. The automated functioning guarantees consistently high-quality papad without the need for manual input, making the production process truly effortless.

Unmatched Quality and Durability

Crafted from food-grade stainless steel, this automatic papad maker emphasizes hygiene and longevity. Its sturdy construction withstands rigorous daily usage without compromising performance. As a trusted choice for Indian distributors, manufacturers, and exporters, the machine comes equipped with a reliable snacks extruder mechanism, ensuring every batch meets expected quality standards. Its user-friendly design caters to all levels of operators, enabling quick and safe operation.

FAQs of Automatic Papad Making Machine:

Q: How does the Automatic Papad Making Machine operate?

A: The machine uses a snacks extruder mechanism to automate the entire papad making process, from forming to shaping. Simply feed the dough into the machine, and it automatically creates uniform papads at a consistent rate, with minimal manual intervention required.Q: What are the benefits of using an automatic papad making machine?

A: Using this machine significantly increases production efficiency, ensures product uniformity, minimizes manual labor, and maintains hygiene due to its stainless steel construction. It is ideal for boosting productivity in snack manufacturing businesses.Q: When should I consider upgrading to this automatic machine?

A: If your current production volume ranges from 5 to 15 kg/hr or if you require faster, more consistent papad output with reduced labor, this automatic machine is an excellent choice. Its particularly beneficial for businesses looking to expand or optimize operations.Q: Where is this papad making machine manufactured and supplied?

A: The machine is manufactured in India and is widely distributed throughout the country. It is available through multiple channels including exporters, retailers, suppliers, and wholesalers, meeting diverse business requirements.Q: What is the process of making papads with this machine?

A: The process involves inserting prepared dough into the machine. The snacks extruder then automates shaping and pressing, producing uniformly sized papads ready for drying or roasting, thus streamlining the traditional manual method.Q: How do I maintain and clean the machine?

A: Thanks to its stainless steel material, maintenance is straightforward. Regularly clean all food-contact surfaces with appropriate sanitizers and check for any dough buildup to ensure smooth operation and product safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Papad Making Machines Category

Dough Kneader With Extruder

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 2 HP

Voltage : 220240 V

Capacity : 10 to 25 Kg/hr

Appalam Machines

Price Range 80000.00 - 280000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 1 TO 10 Horsepower (HP)

Voltage : 110440 Volt (v)

Capacity : 5 to 500 Kg/hr

Semi Automatic Cholafali Machine

Price Range 140000.00 - 1400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 1 TO 10 Horsepower (HP)

Voltage : 110440 Volt (v)

Capacity : 15 TO 500 Kg/hr

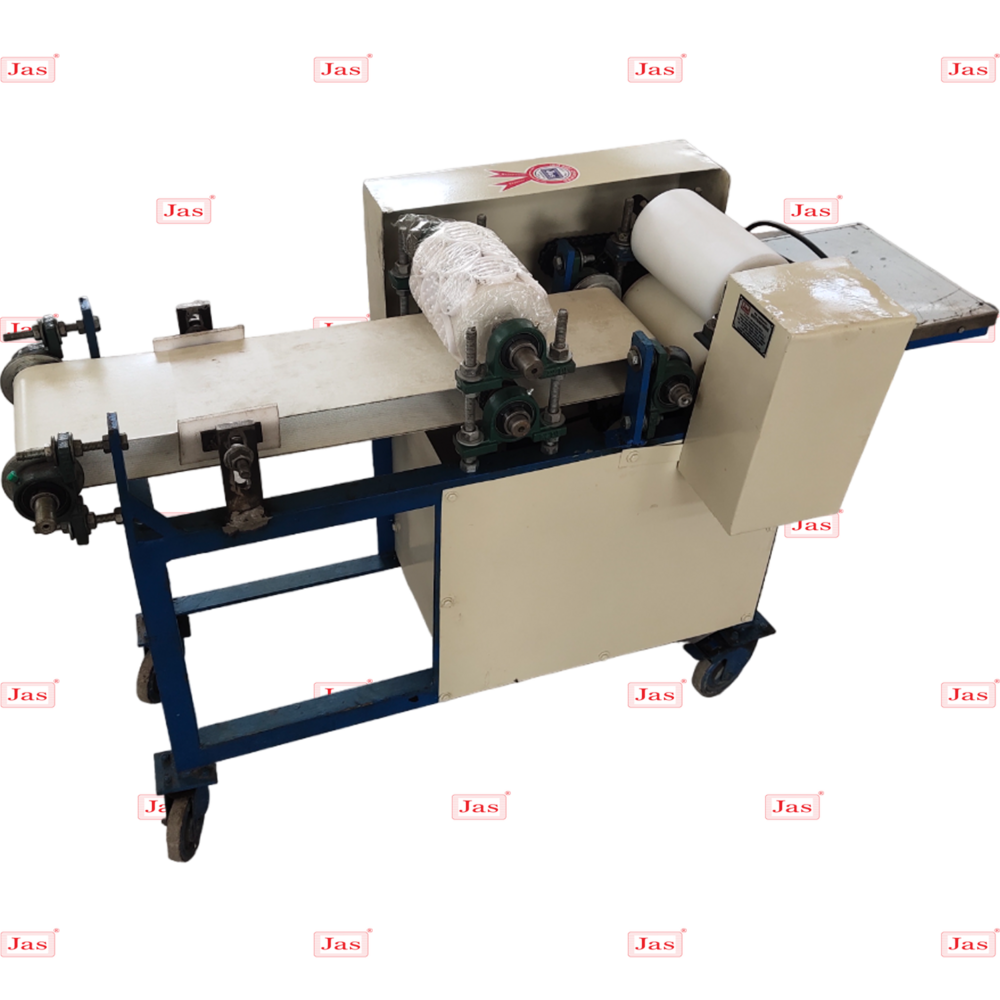

Papad Cutting Machine

Price 40000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Power : 0.51.5 Horsepower (HP)

Voltage : 230 Volt (v)

Capacity : 20018000 Pcs/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS