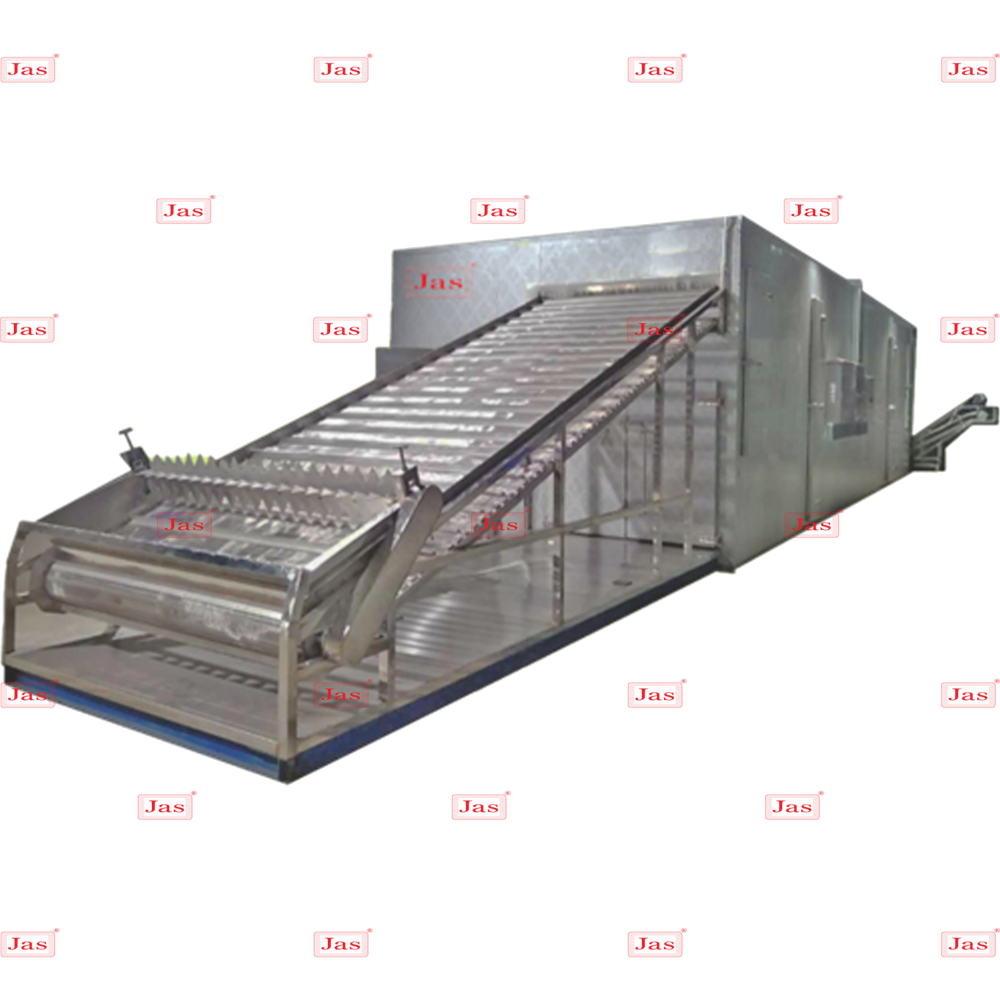

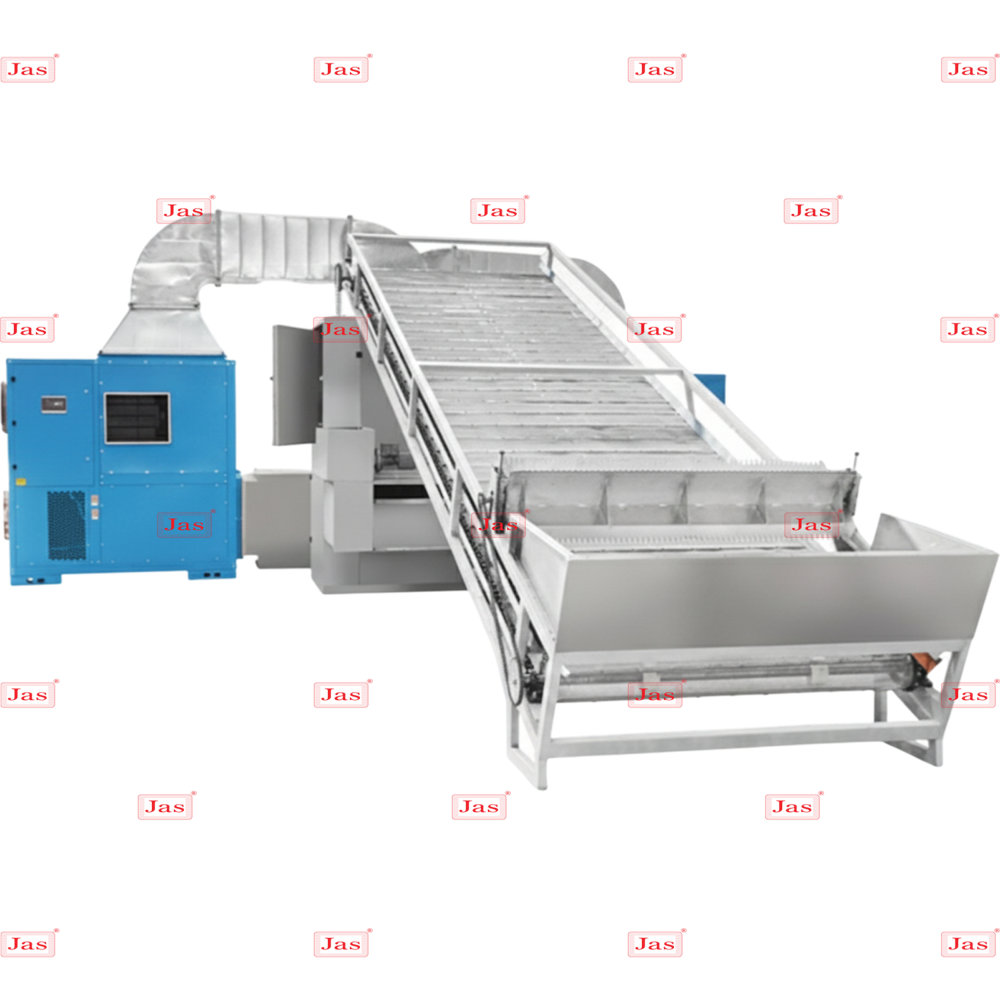

Continuous Belt Dryer

Price 8100000.0 INR/ Number

Continuous Belt Dryer Specification

- Automation Grade

- Continuous Automatic

- Noise Level

- 75 db

- Heating Method

- Heat Pump

- Frequency

- 50 Hertz (HZ)

- Phase

- 3

- Operating Temperature

- 75 Celsius (oC)

- Speed Mode

- Programmable

- Type

- Food Dryer

- Capacity

- 5-6 Ton/day

- Weight (kg)

- 7 Tonne

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 380 Volt (v)

- Power

- 90000 Watt (w)

- Dimension (L*W*H)

- 2.2 x 2 x 1.8 Meter (m)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Continuous Belt Dryer Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 4 Week

About Continuous Belt Dryer

The JAS Belt Dryer with Heat Pump is a high-efficiency, renewable-energy-based continuous drying solution designed for uniform, hygienic, and energy-saving dehydration of food and agricultural products. Engineered with advanced heat pump technology and multi-layer mesh belt system, this dryer ensures precise temperature control, consistent moisture removal, and superior product quality with minimal operating cost.This system is ideal for vegetables, fruits, spices, herbs, grains, pulses and other heat-sensitive products, making it suitable for industrial food processing units, export-oriented plants, and dehydration projects.

Key Features & Advantages-

Energy-Efficient Heat Pump Technology

Utilizes eco-friendly refrigerant and renewable energy principles to significantly reduce power consumption compared to conventional hot air dryers. -

Continuous Mesh Belt Drying System

Multi-layer belt configuration ensures uniform airflow, consistent drying, and high throughput for continuous industrial operation. -

Controlled Low-Temperature Drying (Up to 75C)

Preserves natural color, aroma, taste, nutrients, and texture of the product. -

Closed-Loop Air Circulation

Bottom exhaust with top return air system improves heat recovery, drying efficiency, and operational stability. -

Scalable Industrial Capacity

Available in multiple models to suit small, medium, and large-scale dehydration requirements. -

Hygienic & Robust Construction

Food-grade materials, precision engineering, and compliance with industrial safety and protection standards. -

Low Noise & Safe Operation

Designed with IPx4 protection and Grade-I electrical safety, ensuring reliable and operator-friendly performance.

-

Dehydrated vegetables & fruits

-

Spices, herbs & medicinal plants

-

Grains, pulses & seeds

-

Ready-to-eat food ingredients

-

Agro & food processing industries

-

Lower operating cost & high energy savings

-

Continuous, automated production

-

Uniform drying with minimal product loss

-

Export-quality dehydration results

-

Backed by JAS Enterprises decades of manufacturing expertise

JAS Belt Dryer with Heat Pump is the perfect combination of technology, sustainability, and performance, delivering reliable dehydration solutions for modern food processing industries.

Efficient and ECO-Friendly Food Drying

Experience superior drying performance with our Continuous Belt Dryer, engineered for optimal energy use and environmental sustainability. Featuring a heat pump heating method and programmable automation controlled by a PLC system, this device minimizes energy waste and noise while maximizing output. Compact and robust, it caters to high-volume industrial usage.

Smart Control and Programmable Speed

Take advantage of advanced computerized controls that allow you to precisely program and monitor your drying processes. The intuitive PLC control system ensures stable, automated operation, reducing manual intervention and enabling consistent product quality.

FAQ's of Continuous Belt Dryer:

Q: How does the Automatic Continuous Belt Dryer ensure energy efficiency and low noise operations?

A: This dryer utilizes a heat pump technology and a PLC-controlled system to optimize energy usage, resulting in lower power consumption. Its ECO-friendly design and advanced insulation help keep operational noise levels under 75 dB, making it suitable for noise-sensitive environments.Q: What types of food products can be processed using this belt dryer?

A: The machine is designed for diverse food products that require uniform drying, such as fruits, vegetables, grains, and herbs, ensuring optimal moisture removal with minimal manual intervention.Q: When should I use the programmable speed mode feature?

A: Programmable speed mode should be utilized when different drying durations or product types demand variable belt speeds. This customization ensures efficient drying for batches with unique moisture or density characteristics.Q: Where is the Continuous Belt Dryer typically installed and used?

A: It is primarily installed in industrial food processing plants, manufacturing facilities, and commercial food drying operations across India, serving as a critical component for companies distributing, exporting, or wholesaling dried food products.Q: What is the drying process for this machine and how does the PLC control system benefit operations?

A: Food material is transported on a continuous belt through a controlled chamber where hot air from the heat pump circulates evenly. The built-in PLC system automates speed, temperature, and humidity adjustments, ensuring precise and consistent drying cycles.Q: How can users benefit from the computerized and automated features of this dryer?

A: Users enjoy reduced labor input, better consistency in drying results, lower operational costs, and effortless process monitoring and adjustment, all thanks to the system's computerized automation and PLC-based control interface.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dehydrator - Dryer Machine Category

Five-Stage Continuous Conveying Belt Dryer for Vegetable Dehydration

Price 390000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Operating Temperature : 4080 Celsius (oC)

Color : Blue

Noise Level : 80 db

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS