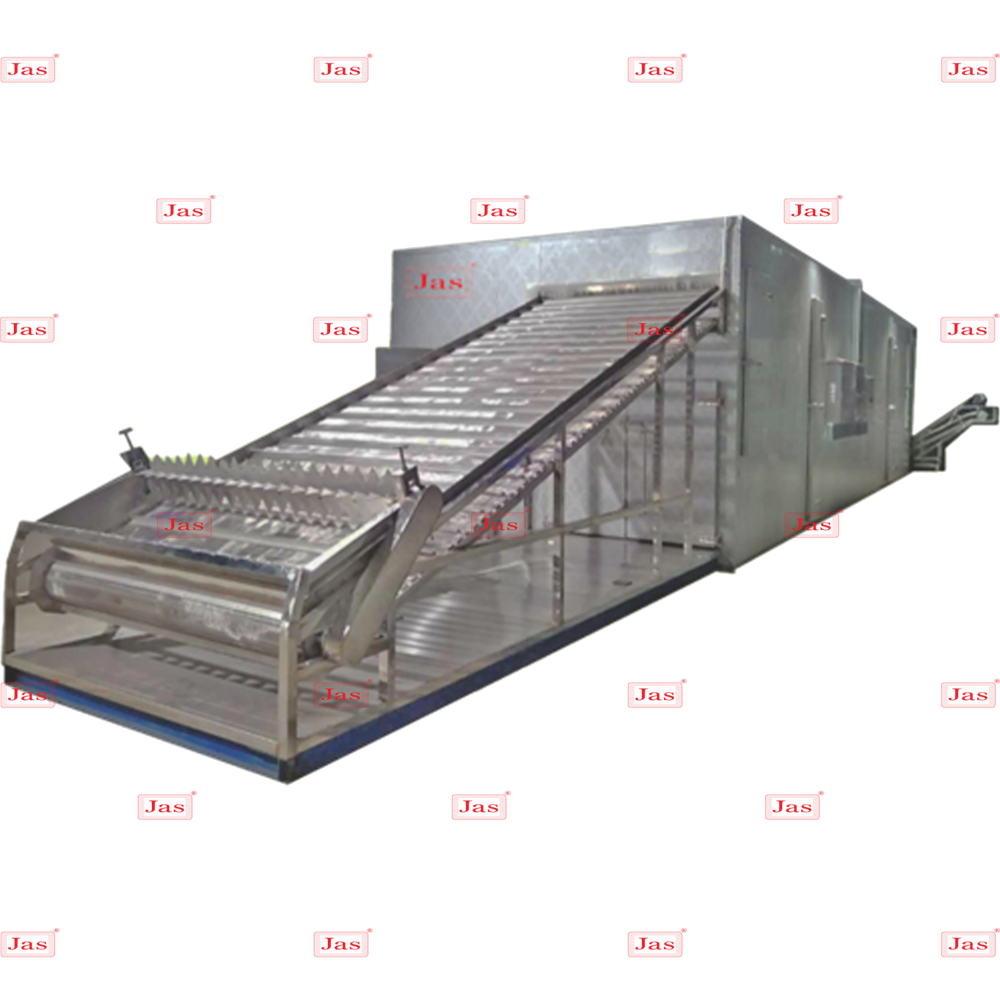

Five-Stage Continuous Conveying Belt Dryer for Vegetable Dehydration

Price 390000.0 INR/ Unit

Five-Stage Continuous Conveying Belt Dryer for Vegetable Dehydration Specification

- Noise Level

- 80 db

- Heating Method

- Heat Pump

- Frequency

- 50/60 Hertz (HZ)

- Phase

- 3 Phase

- Operating Temperature

- 40-80 Celsius (oC)

- Material

- Stainless Steel

- Capacity

- 200 to 2000 Kg/hr

- Feature

- Lower Energy Consumption, Compact Structure, High Efficiency, ECO Friendly, Low Noice

- Color

- Blue

- Warranty

- 1 Year against manufacturing defect

Five-Stage Continuous Conveying Belt Dryer for Vegetable Dehydration Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 1 Week

About Five-Stage Continuous Conveying Belt Dryer for Vegetable Dehydration

Our 5-Stage Continuous Conveying Dryer is a high-performance, industrial-grade solution designed for the continuous dehydration of various vegetables and spices. This versatile equipment is engineered to handle large-scale processing of onion, garlic, turmeric, ginger, carrot, cabbage, and chilies with precision and efficiency.

By utilizing a vertical 5-tier belt system, this dryer ensures maximum moisture removal while maintaining the color, aroma, and nutritional value of the produce.

Technical Specifications

-

Dryer Type: Continuous Multi-Stage Belt Dehydrator

-

Number of Stages: 5 Vertical Conveying Belts

-

Heating System: Steam/Electric/Thermic Fluid Heating Coils

-

Material of Construction: Food-grade Stainless Steel (SS304/SS316)

-

Drive System: Individual Variable Speed Drives for each belt

-

Airflow Logic: Induced Draft via High-Efficiency Exhauster Fans

-

Temperature Control: Automated Digital Temperature Controllers

Key Features & Functional Advantages

-

Advanced Cascade Design: The material is fed onto the top belt and automatically transfers to subsequent lower belts. This "dropping" action flips the product, ensuring uniform drying and preventing clumping.

-

Precise Thermal Management: Equipped with high-quality heating coils that allow for zoned temperature control. This prevents scorching of sensitive products like cabbage and garlic.

-

Efficient Airflow Dynamics: The dryer utilizes a permeable bed drying technique where hot air passes through the material. Moist air is effectively extracted by top-mounted exhaust fans, preventing re-hydration.

-

Customizable Residence Time: With individual drives for each belt, operators can precisely control how long the product stays at each stage, optimizing the drying curve for different moisture contents.

-

Hygienic & Robust: Built to meet international food safety standards, featuring easy-to-clean surfaces and heat-resistant conveying belts.

Applications

This plant is ideal for food processing units specializing in:

-

Dehydrated Flakes: Cabbage, Onion, Garlic.

-

Root Vegetables: Carrots, Ginger, Turmeric slices.

-

Spices: Whole Red Chilies and Leafy Herbs.

Why Choose Our Continuous Dryer?

Compared to traditional tray dryers, our 5-stage system offers lower labor costs, reduced floor space requirements, and significantly higher thermal efficiency. It is the perfect investment for businesses looking to scale their production of high-quality dehydrated exports.

Engineered for High-Volume Vegetable Drying

With its advanced five-stage belt system, this dryer streamlines the dehydration process, ensuring rapid, uniform moisture removal while preserving the quality, color, and nutrients of vegetables. The spacious, stainless steel construction not only guarantees durability but also meets stringent hygienic requirements suitable for the food-processing sector.

Superior Energy Efficiency and Quiet Operation

Employing a heat pump heating method, the dryer achieves lower energy consumption compared to conventional drying methods. Its eco-friendly design and noise level of just 80 db contribute to a safer, more comfortable working environment, making it ideal for facilities focused on sustainability and user well-being.

FAQ's of Five-Stage Continuous Conveying Belt Dryer for Vegetable Dehydration:

Q: How does the five-stage continuous conveying belt dryer operate for vegetable dehydration?

A: This dryer utilizes five sequential belt sections to consistently move vegetables through controlled zones of heated air (40-80C). The process ensures even dehydration as the products travel across each stage, optimizing drying efficiency and preserving vegetable quality.Q: What are the main benefits of using this dryer for vegetable processing?

A: The main advantages include high efficiency, reduced energy consumption, eco-friendly operation, uniform drying, minimized nutrient loss, and low noise, making it ideal for large-scale vegetable dehydration.Q: When is it suitable to use this five-stage belt dryer?

A: This dryer is most suitable for processing large volumes of vegetables (200 to 2000 kg/hr) in commercial or industrial settings where uniform drying, energy savings, and product quality consistency are essential.Q: Where can this dryer be installed and used?

A: It is designed for industrial kitchens, food processing factories, and vegetable dehydration plants, particularly those located in India and supplied by distributors, exporters, manufacturers, and wholesalers.Q: What is the drying process within the machine?

A: Vegetables are loaded onto the first belt, and as they progress through each stage, hot air from the heat pump circulates to extract moisture. The sequential design allows for gradual dehydration, ensuring every piece dries uniformly before collection at the end.Q: How does the low energy feature impact operational costs?

A: The dryer's heat pump heating method requires less energy than traditional systems, directly reducing electricity expenses and contributing to a lower environmental footprint for ongoing operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dehydrator - Dryer Machine Category

Continuous Belt Dryer

Price 8100000.0 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 2.2 x 2 x 1.8 Meter (m)

Speed Mode : Programmable

Frequency : 50 Hertz (HZ)

Weight (kg) : 7 Tonne

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS