Automatic Potato Chips Making Machine

Price 29500 INR/ Unit

Automatic Potato Chips Making Machine Specification

- Capacity

- 300 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Automatic Potato Chips Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO 9001

About Automatic Potato Chips Making Machine

An automatic potato chips making machine is a sophisticated food processing device designed to streamline the production of potato chips on a commercial scale. Typically, such machines feature:

-

Automatic Feeding System: Efficiently feeds raw potatoes into the machine for slicing.

-

Slicing Mechanism: Uniformly slices potatoes into thin, even slices, crucial for consistent chip quality.

-

Frying Chamber: Cooks the potato slices in hot oil to achieve the desired crispiness and texture.

-

Oil Filtering System: Filters and recycles oil, optimizing usage and maintaining cleanliness.

-

Seasoning Application: Coats chips evenly with seasoning, either automatically or via manual adjustment.

-

Control Panel: Allows operators to adjust parameters such as slicing thickness, frying time, and seasoning levels.

These machines are essential for large-scale production due to their efficiency, consistency, and ability to reduce manual labor. They ensure uniform quality in every batch of potato chips produced, meeting the demands of the market effectively.

Exceptional Efficiency and Capacity

With a robust capacity of 300 kg per hour and high efficiency, this automatic machine streamlines potato chips production for businesses of all sizes. Its smart design minimizes manual intervention and maximizes output without compromising on product quality. The compact structure enables easy integration into existing processing lines.

Sustainable and Cost-Effective Operation

Engineered with eco-friendly principles, this machine reduces its carbon footprint and operating costs. The low noise levels provide a serene working environment, while its lower energy consumption translates to significant savings in utility bills, making it an attractive solution for eco-conscious and cost-focused enterprises.

FAQs of Automatic Potato Chips Making Machine:

Q: How does the automatic potato chips making machine contribute to eco-friendly production?

A: The machine is engineered to minimize energy consumption and environmental impact. Its efficient operating system uses less electricity, and its low-noise function reduces noise pollution, ensuring a greener and more sustainable production process.Q: What is the process flow for making potato chips with this automatic machine?

A: The potato chips making machine automates peeling, slicing, frying, and seasoning. Simply load fresh potatoes, and the machine handles the rest, delivering crispy chips consistently at a rate of up to 300 kg per hour.Q: When is maintenance recommended for optimal operation?

A: Routine maintenance should be conducted according to the manufacturers guidelines, typically after every production cycle or as specified in the user manual, ensuring consistent performance and longevity of the equipment.Q: Where can the machine be installed for best performance?

A: Thanks to its compact design, the machine suits varied settingsfrom industrial food processing plants to large commercial kitchens and mid-sized snack production facilities. It requires a stable 230/440 Volt power supply and adequate space for safe, efficient operation.Q: What are the major benefits of using this potato chips machine for businesses?

A: Businesses benefit from high output, reduced labor costs due to automation, energy efficiency, and a quieter workplace. Additionally, its eco-friendly attributes and reliable technology make it ideal for both small and large-scale food producers.Q: How user-friendly is the automatic potato chips making machine?

A: The machine is designed for ease of use. Operators can manage it with minimal training, thanks to intuitive controls and automated processing, reducing the need for specialized skills and streamlining the production process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Potato Chips Making Machines Category

Chips Making Machine

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 100200 kg/hr

Voltage : 220 Volt (v)

Computerized : No

Circular Batch Fryer

Price 5000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 40120 kg/hr (varies by model)

Voltage : 220440 V

Computerized : No

Fully Automatic Potato Chips Plant

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 200 TO 500 Kg/hr

Voltage : 110440 Volt (v)

Computerized : Yes

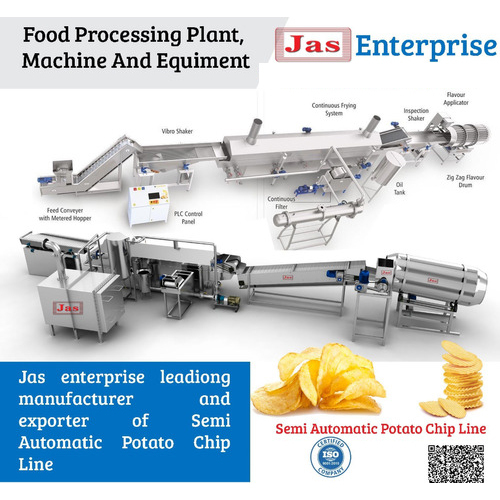

Semi-Automatic Potato Chip Line

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Capacity : 200 Kg/day

Voltage : 110 to 440 Volt (v)

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS