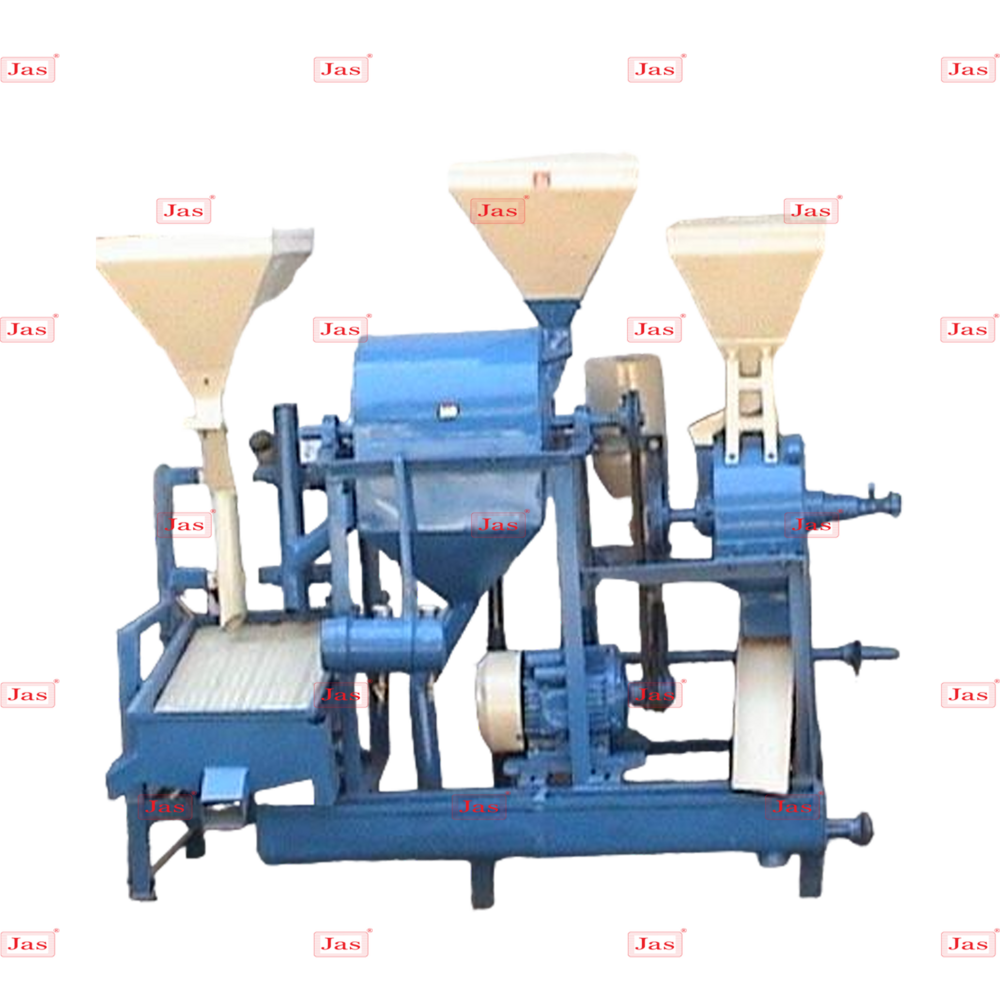

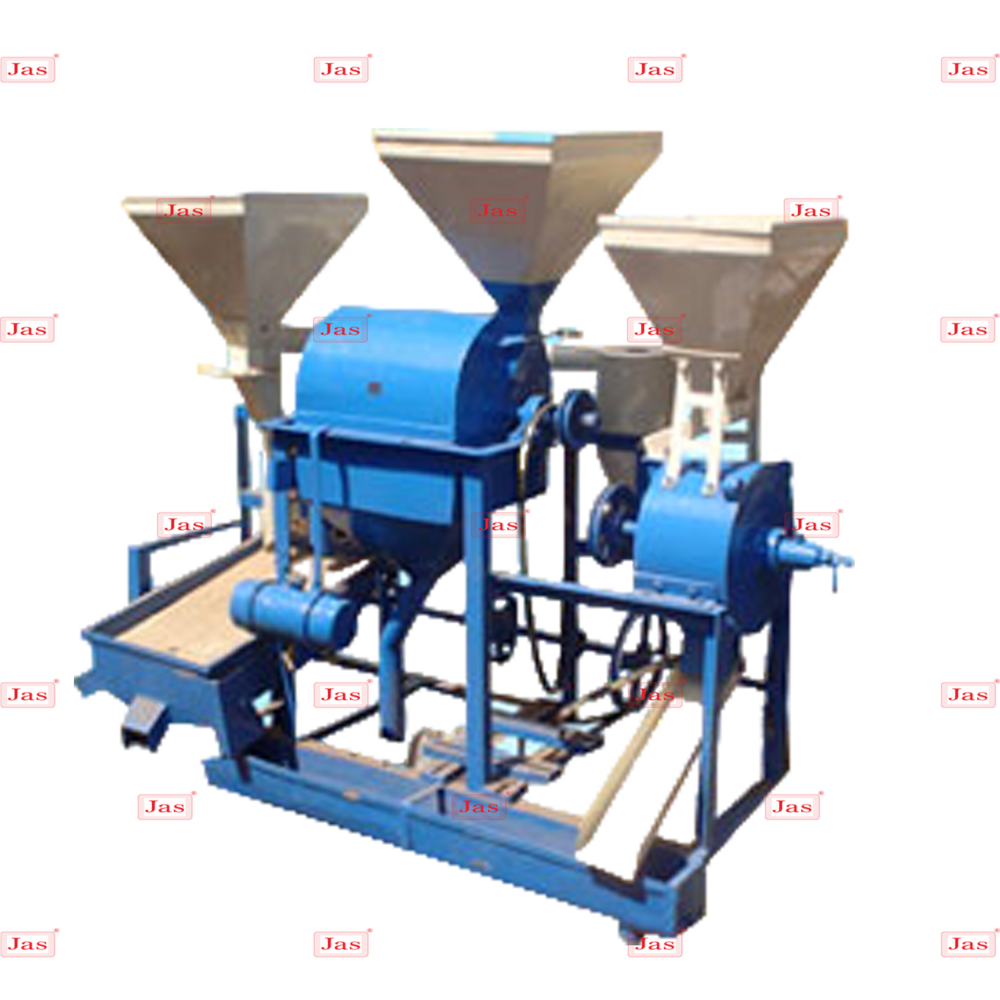

Black Gram Skin Removing Machine

Price 170500 INR/ Unit

Black Gram Skin Removing Machine Specification

- Frequency

- 50-60 Hertz (HZ)

- Automation Grade

- Semi Automatic

- Phase

- Single Phase / Three Phase

- Features

- Easy Operation, Durable Build, Low Maintenance

- Capacity

- 60-200 Kg/hr

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Voltage

- 230/440 Volt (v)

- Power

- 2-5 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Black Gram Skin Removing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Delivery Time

- 5-10 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Black Gram Skin Removing Machine

The Black Gram Skin Removing Machine is a highly efficient and durable agricultural processing unit specifically engineered to remove the outer skin (husk) of black gram, also known as urad dal. Widely used in food processing industries, dal mills, and small-scale production units, this machine plays a crucial role in preparing black gram for further processing, such as polishing or splitting.

Constructed with high-quality materials, the machine utilizes abrasive or frictional techniques to gently remove the tough outer layer of the black gram without damaging the inner seed. This ensures minimal wastage and maximum yield. Its robust design allows for continuous operation, while its user-friendly interface makes it easy to operate and maintain.

Efficient Black Gram De-Hulling

Specially engineered for removing skins from black gram, this machine boasts a robust and durable build, offering high efficiency and reliability. Its semi-automatic operation enables easy handling, while the compact design ensures smooth integration into small or large processing units. With a production capacity of 60-200 kg/hr, it suits varied commercial demands.

User-Friendly Operation and Low Maintenance

Operated with a manual control system, this machine is straightforward to use and requires minimal maintenance. The clear design makes it accessible for staff with basic technical skills. Its eco-friendly operations ensure low energy consumption and low noise output, addressing sustainability and workplace comfort.

Versatile Power and Warranty

Compatible with both single and three-phase electrical systems, this machine supports 230/440V, making installation flexible and convenient. Its power requirements range from 2 to 5 HP, adapting to available resources. Every purchase is backed by a one-year warranty against manufacturing defects, assuring buyers of its manufacturing quality.

FAQ's of Black Gram Skin Removing Machine:

Q: How does the Black Gram Skin Removing Machine operate?

A: The machine functions via a semi-automatic, manual control system. Operators load black gram into the hopper, and the de-hulling process proceeds smoothly with minimal intervention, ensuring high efficiency and consistent output.Q: What types of power supply are compatible with this machine?

A: This machine operates on either single-phase or three-phase electrical connections, supporting voltages of 230 or 440 volts. This makes it adaptable to most power setups in processing facilities across India.Q: Where can the Black Gram Skin Removing Machine be installed?

A: Owing to its compact structure, the machine can be installed in any small to medium-scale processing unit, warehouse, or commercial food processing setup. Its versatile design suits distributors, exporters, manufacturers, retailers, and wholesalers.Q: What are the key benefits of using this de-hulling machine?

A: Key advantages include easy operation, low maintenance needs, durable construction, high energy efficiency, and low noise levels. Its eco-friendly design further promotes sustainability in processing operations.Q: What is the average production capacity and is it suitable for large operations?

A: The machine can handle between 60 to 200 kilograms of black gram per hour, making it suitable for small to medium processing demands. For larger scale operations, multiple units can be used for increased throughput.Q: How often does the machine require servicing or maintenance?

A: Thanks to its low maintenance design, the machine typically only requires periodic checks and basic upkeep, such as cleaning and inspection for wear, ensuring trouble-free long-term operation.Q: What warranty is provided with this machine?

A: The machine comes with a one-year warranty covering manufacturing defects, providing buyers with peace of mind regarding the product's quality and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Grains Processing Machines Category

Grains Pulses Dal Emery Scourer

Price Range 135000.00 - 285000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 6 months against any manufacturing defects.

Material : Stainless Steel

Vegetable Dehydration Plant

Price 390000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : Yes

Material : Other, Steel

Besan Sattu Making Machine

Price 30000 INR / Piece

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defect at our side

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Pulse Lentils Polishers

Price Range 50000.00 - 95000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Material : Stainless Steel

Feature : Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free