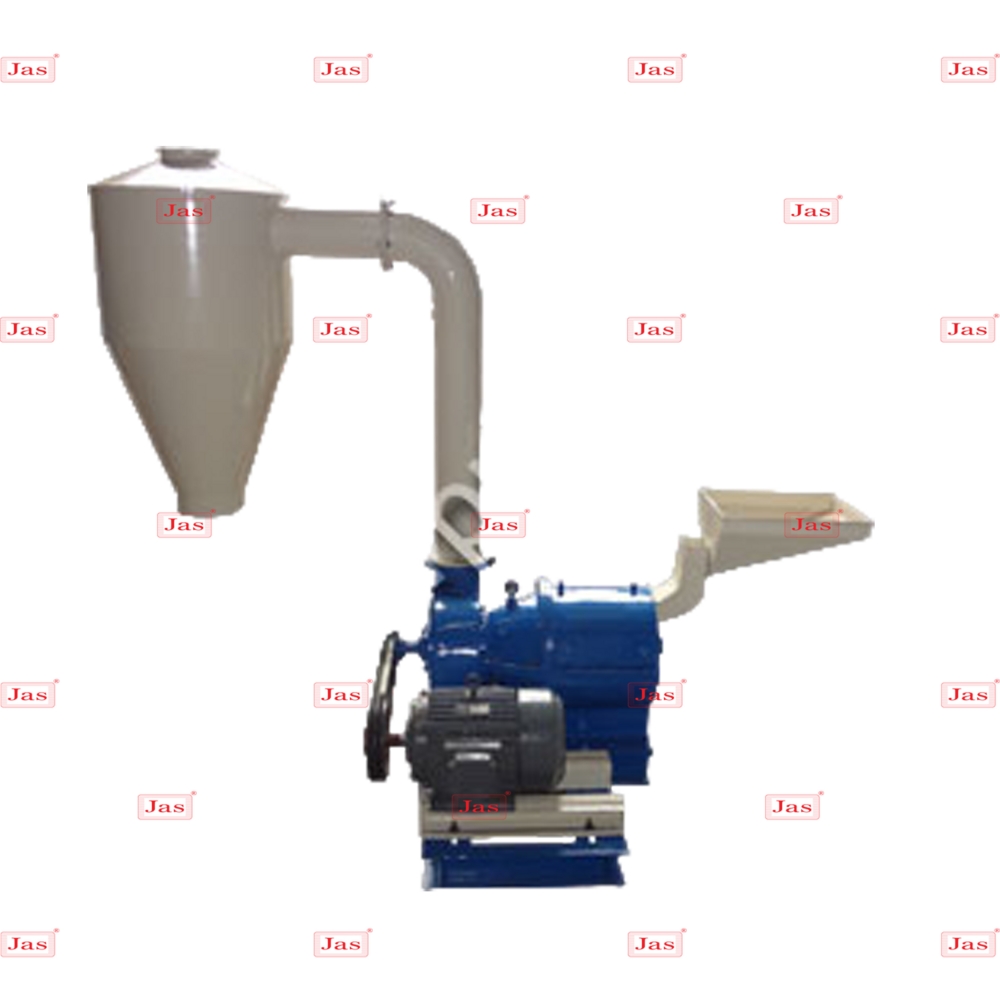

Besan Sattu Making Machine

Price 30000 INR/ Piece

Besan Sattu Making Machine Specification

- Automation Grade

- Semi Automatic

- Phase

- Single Phase / Three Phase

- Frequency

- 50-60 Hertz (HZ)

- Capacity

- 30-2000 Kg/hr

- Voltage

- 230/440 Volt (v)

- Power

- 2-200 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Warranty

- One year against manufacturing defect at our side

Besan Sattu Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Besan Sattu Making Machine

Besan Sattu Making Machine is an advanced food processing equipment designed specifically for grinding roasted pulses, primarily chickpeas (gram), into fine flour known as besan or sattu. This machine plays a vital role in the production of besan, which is widely used in Indian cuisine for making snacks, sweets, and various traditional dishes, as well as sattu, a nutritious flour used in beverages and health foods.

The machine is engineered to deliver high efficiency, uniform grinding, and consistent particle size to ensure superior product quality. It typically features robust grinding chambers fitted with high-grade grinding stones or stainless steel blades, which can be adjusted to achieve the desired flour texture from coarse to ultra-fine powder. The roasting and grinding processes are optimized to retain the nutritional value and flavor of the pulses.

Innovative Semi-Automatic Flour Processing

Utilizing modern engineering, the Besan Sattu Making Machine streamlines the production of besan and sattu with minimal manual effort. Its semi-automatic operation allows for efficient workflow, increasing productivity while maintaining consistent product quality at varying scales of output.

Eco-Friendly and Energy-Saving Operation

Designed with sustainability in mind, the machine produces low noise and consumes less energy, making it a greener choice for businesses. Its ECO-friendly attributes combine with robust construction, ensuring durability and a reduced carbon footprint throughout its operational life.

FAQs of Besan Sattu Making Machine:

Q: How does the Besan Sattu Making Machine contribute to eco-friendly production?

A: The machine is designed with low energy consumption and minimal noise emissions, reducing environmental impact. Its efficient motor and compact structure further optimize resource usage, making it a sustainable choice for flour production.Q: What is the capacity range of the Besan Sattu Making Machine and how does it suit different businesses?

A: The machine processes between 30 and 2000 kilograms per hour, making it suitable for small-scale retailers as well as high-volume distributors, exporters, and manufacturers. This wide capacity range supports diverse operational needs.Q: When should I consider using a semi-automatic besan sattu machine rather than a manual one?

A: Businesses seeking higher efficiency, consistent output, and lower labor involvement should opt for the semi-automatic model. It offers improved speed, reliability, and product quality compared to manual alternatives.Q: Where can the Besan Sattu Making Machine be installed and what are the power requirements?

A: The machine can be set up in flour mills, processing units, and food manufacturing facilities across India. It is compatible with both 230 and 440 Volt supplies, operating on single or three-phase electricity at 50-60 Hertz.Q: What is the process for operating the Besan Sattu Making Machine?

A: To operate, feed raw grains into the hopper, set the required parameters, and start the machine. The semi-automatic design allows for streamlined processing with minimal supervision until the final product is collected.Q: What are the key benefits of using this machine for besan sattu production?

A: Key benefits include high efficiency, reduced energy costs, low noise levels, and compact design. The one-year warranty ensures peace of mind against manufacturing defects, supporting business continuity for suppliers and end-users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Grains Processing Machines Category

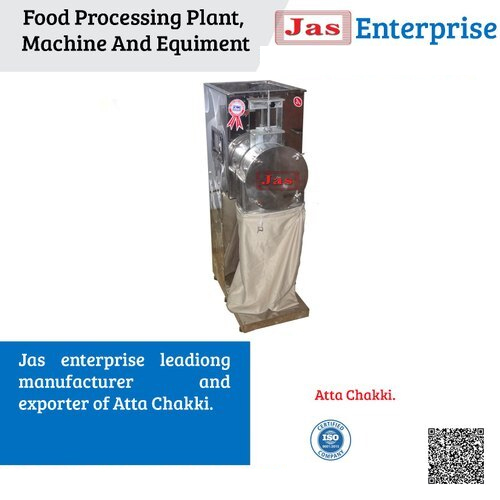

Automatic Atta Chakki Machine

Price 28000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : Other, Automatic Feeding, Consistent Output

Capacity : 30 to 170 Kg/hr Kg/hr

Voltage : 220440 V

Atta Chakki Machine

Price 16500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : Other, High Efficiency, Easy to Operate, Robust Construction

Capacity : 2030 kg/hr

Voltage : 220240 Volt (v)

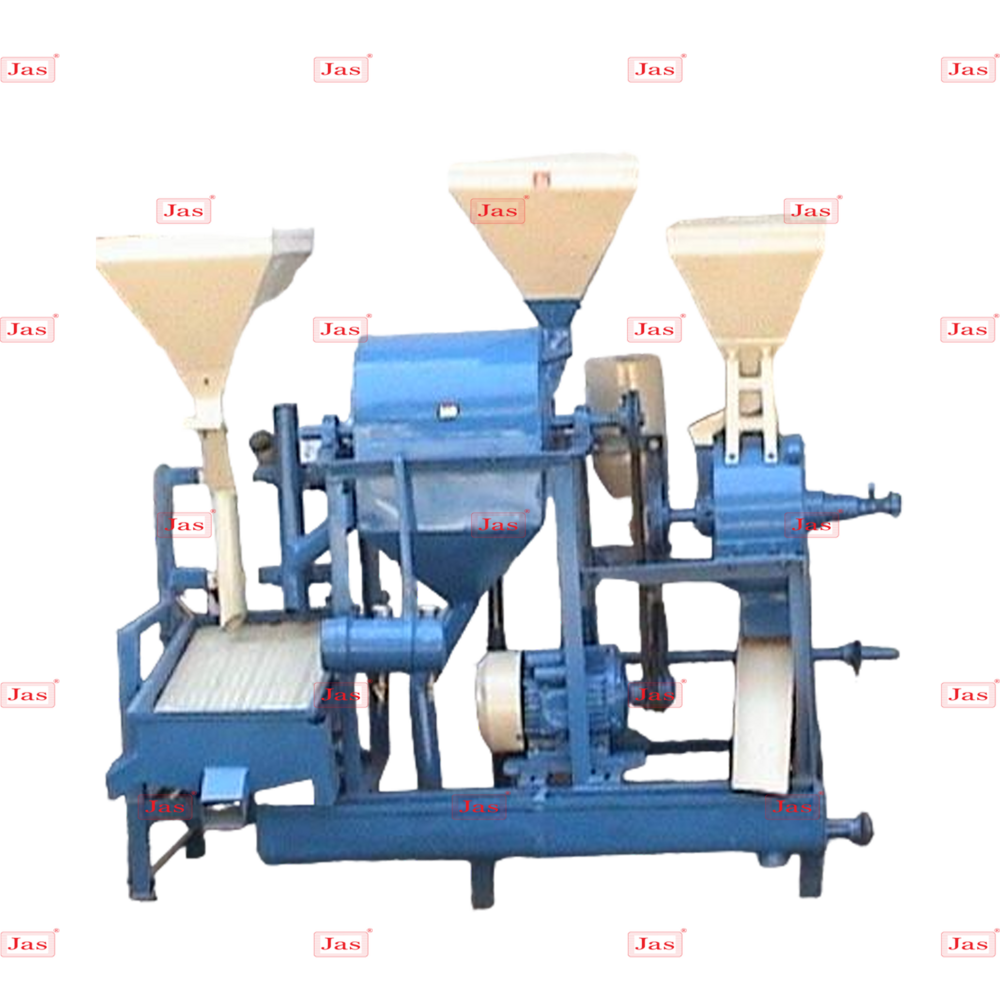

Mini Dal Mill Machine

Price 170000 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic : Yes

Feature : ECO Friendly, Compact Structure, Lower Energy Consumption, High Efficiency

Capacity : 60210 Kg/hr

Voltage : 230/440 Volt (v)

Black Gram Skin Removing Machine

Price 170500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Capacity : 60200 Kg/hr

Voltage : 230/440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS