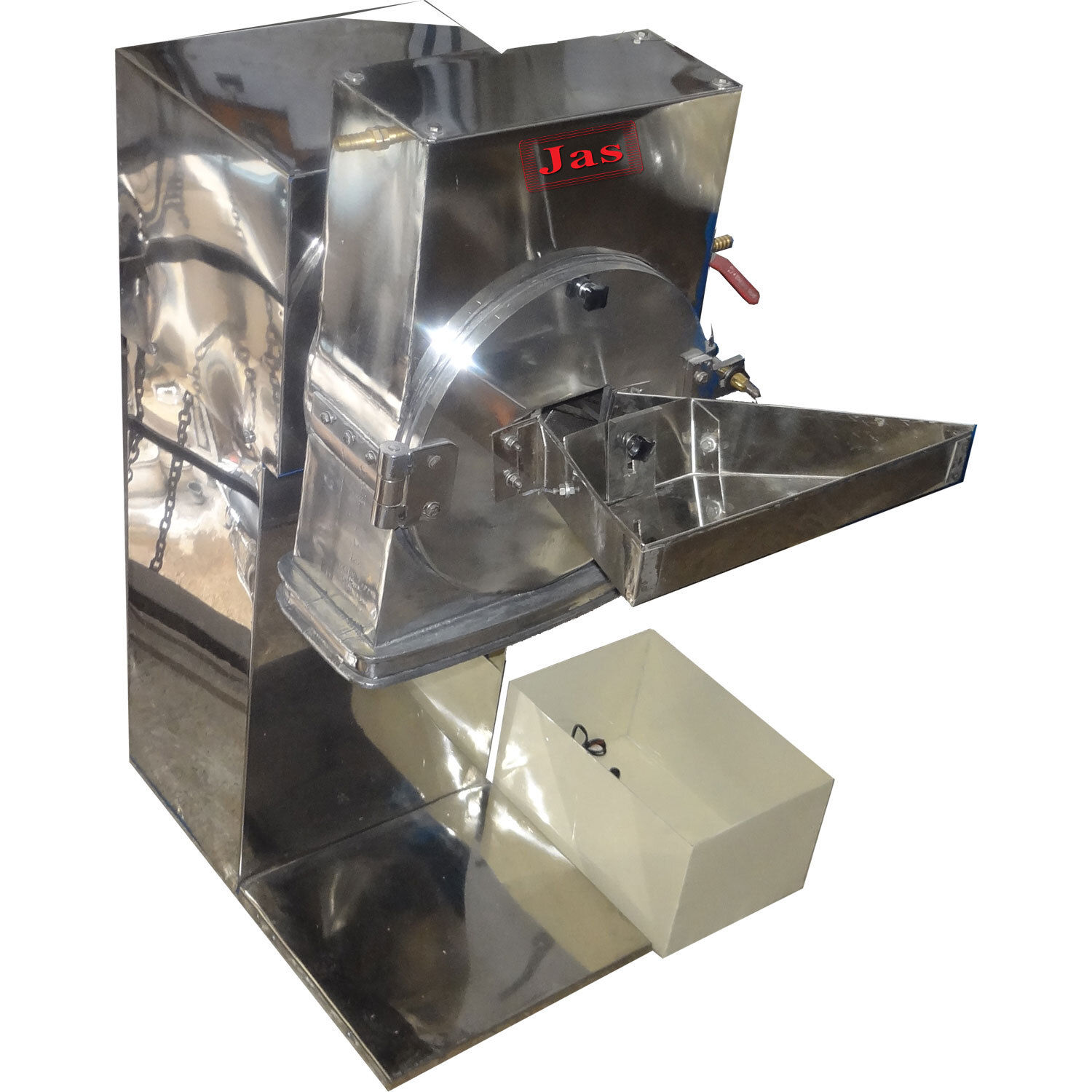

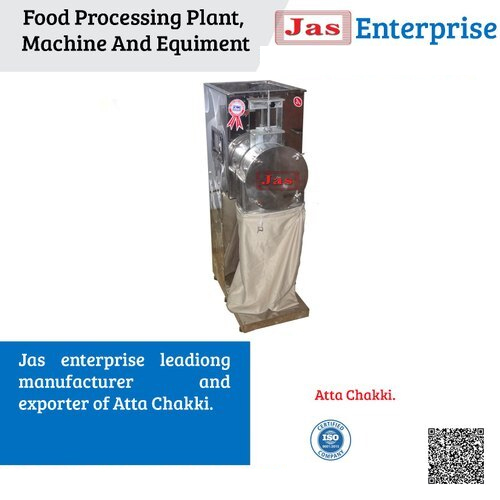

Automatic Atta Chakki Machine

Price 28000 INR/ Unit

Automatic Atta Chakki Machine Specification

- Power Source

- Electric

- Automation Grade

- Automatic

- Function Type

- Dry Grinding

- Heating Method

- Mechanical

- Speed Mode

- Variable Speed

- Features

- Stainless Steel Construction, Dust Free Operation, Low Maintenance

- Feeding System

- Automatic Hopper

- Noise Level

- <80 dB

- Operating Temperature

- Ambient

- Frequency

- 50/60 Hz

- Phase

- Single/Three Phase

- Machine Type

- Heavy Duty Atta Chakki

- Product Type

- Automatic Atta Chakki Machine

- General Use

- Grinding Wheat and Other Grains

- Material

- Stainless Steel

- Type

- Floor Mill

- Capacity

- 30 to 170 Kg/hr Kg/hr

- Weight (kg)

- Approx. 120-400 kg (varies by model)

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- Digital/Push Button

- Installation Type

- Free Standing

- Voltage

- 220-440 V

- Power

- 2 to 10 HP Horsepower (HP)

- Dimension (L*W*H)

- Approx. 40 x 20 x 50 inch

- Raw Material

- Wheat, Grains

- Feature

- Automatic Feeding, Consistent Output

- Color

- Silver/Grey

- Warranty

- One year against manufacturing defects at our site

- Output Fineness

- Up to 120 mesh

- Hopper Capacity

- Approx. 20-50 kg

- Suitable Application

- Commercial and Domestic Flour Milling

- Gear Material

- High Tensile Steel

- Motor Type

- Copper Winding, Induction Motor

- Safety System

- Overload Protection, Emergency Stop

- Grinding Chamber

- Stainless Steel

- Cleaning System

- Easy Removable Parts

- Belt Type

- V-Belt Driven

Automatic Atta Chakki Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, Delhi, , South India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Punjab, Gujarat, Uttar Pradesh, Karnataka, North India, Central India, Odisha, West India, Chhattisgarh, All India

About Automatic Atta Chakki Machine

Advanced Performance for Flour Milling

This heavy-duty atta chakki machine combines high power (2 to 10 HP) with computerized automatic operation for seamless flour production. Its stainless steel structure and V-belt driven system contribute to consistent and dust-free output, making it ideal for businesses or home use requiring substantial milling volumes.

Smart Safety and Easy Maintenance

Outfitted with overload protection, an emergency stop, and easily removable parts, this machine places safety and convenience at the forefront. Cleaning is simplified for operators, minimizing downtime and ensuring a hygienic milling environment.

User-Friendly Digital Controls

The set-and-forget digital or push button interface, coupled with automatic hopper feeding, enables users to operate with minimal intervention. Adjustable speed, free-standing installation, and adaptability to a range of voltages further enhance usability in diverse settings.

FAQs of Automatic Atta Chakki Machine:

Q: How does the automatic atta chakki machine ensure the safety of its users during operation?

A: The machine is equipped with multiple safety mechanisms, including overload protection to prevent damage under excessive load and an emergency stop button for immediate shutdown. These features help ensure user safety during both commercial and domestic use.Q: What types of grains can be processed using this automatic atta chakki?

A: This machine is primarily designed for grinding wheat but can also process various grains suitable for flour milling. Its heavy-duty construction and variable speed modes allow it to handle a wide range of dry grains efficiently.Q: When should the grinding chamber and parts be cleaned, and is the cleaning process complicated?

A: Cleaning should be performed after each milling session to maintain hygiene and optimal performance. The parts are designed to be easily removable, simplifying the cleaning process and reducing machine downtime.Q: Where can this atta chakki machine be installed, and what are the site requirements?

A: The machine is free-standing and can be installed in commercial milling units, bakeries, or even residential spaces with adequate space and proper electrical supply (220-440V, single or three phase). Its approximate dimension is 40 x 20 x 50 inches, so ensure sufficient clearance for operation and maintenance.Q: What benefits does the induction motor with copper winding provide?

A: A copper winding induction motor offers enhanced efficiency, longer operational life, and better resistance to heat, ensuring the machine runs reliably during prolonged use. It also contributes to lower energy consumption compared to standard motors.Q: How does the digital control system improve flour milling operations?

A: Digital and push button controls streamline the user experience by allowing easy adjustments of settings, consistent output fineness (up to 120 mesh), and efficient operation, all of which help save time and reduce operator errors.Q: What warranty and support are offered with this atta chakki machine?

A: The product comes with a one-year warranty against manufacturing defects, applicable at the manufacturers site. This support ensures peace of mind, allowing users to focus on milling operations without concerns about unexpected breakdowns.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Grains Processing Machines Category

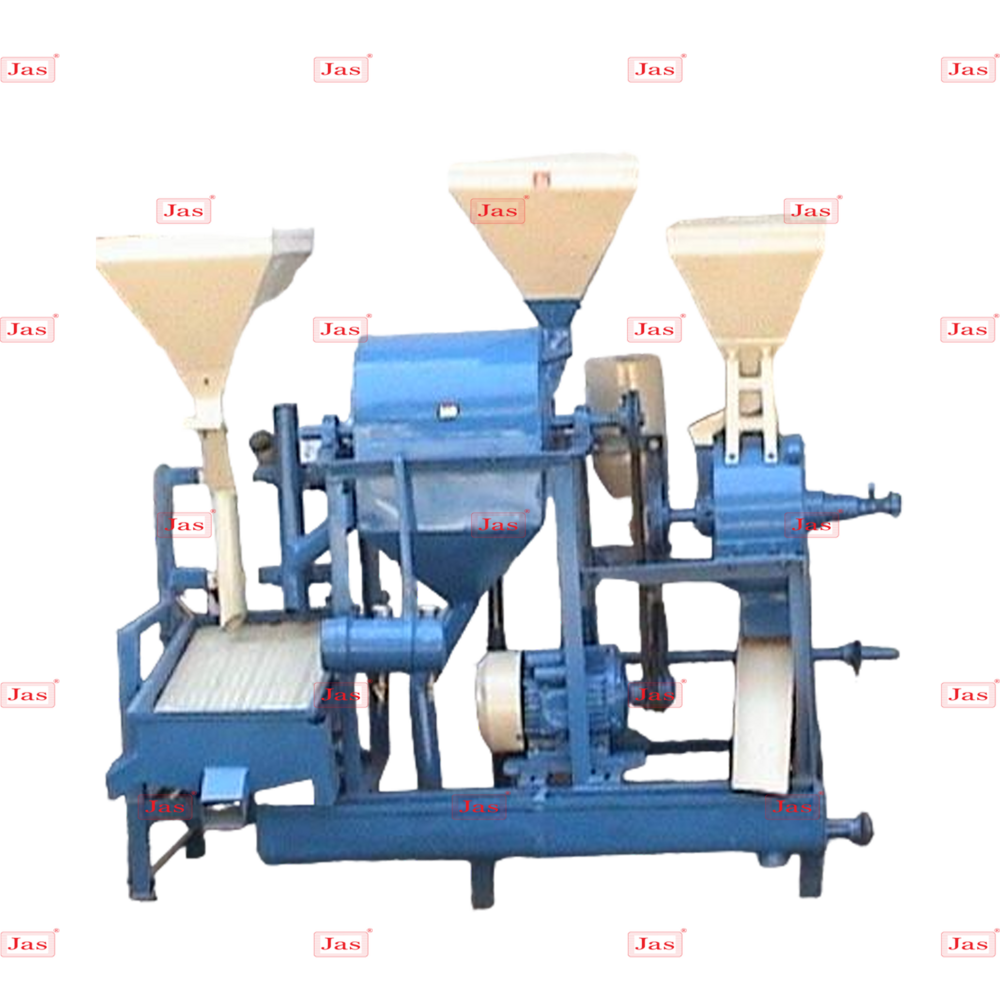

Atta Chakki Machine

Price 16500 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High Efficiency, Easy to Operate, Robust Construction

Warranty : One year against manufacturing defects at our site

Capacity : 2030 kg/hr

Material : Other, Mild Steel

Black Gram Skin Removing Machine

Price 170500 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Warranty : One year against manufacturing defect at our side

Capacity : 60200 Kg/hr

Wheat Flour Mill Machine

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency, Compact Structure

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Capacity : 30170 Kg/hr

Material : Stainless Steel

Besan Sattu Making Machine

Price 30000 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Warranty : One year against manufacturing defect at our side

Capacity : 302000 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free