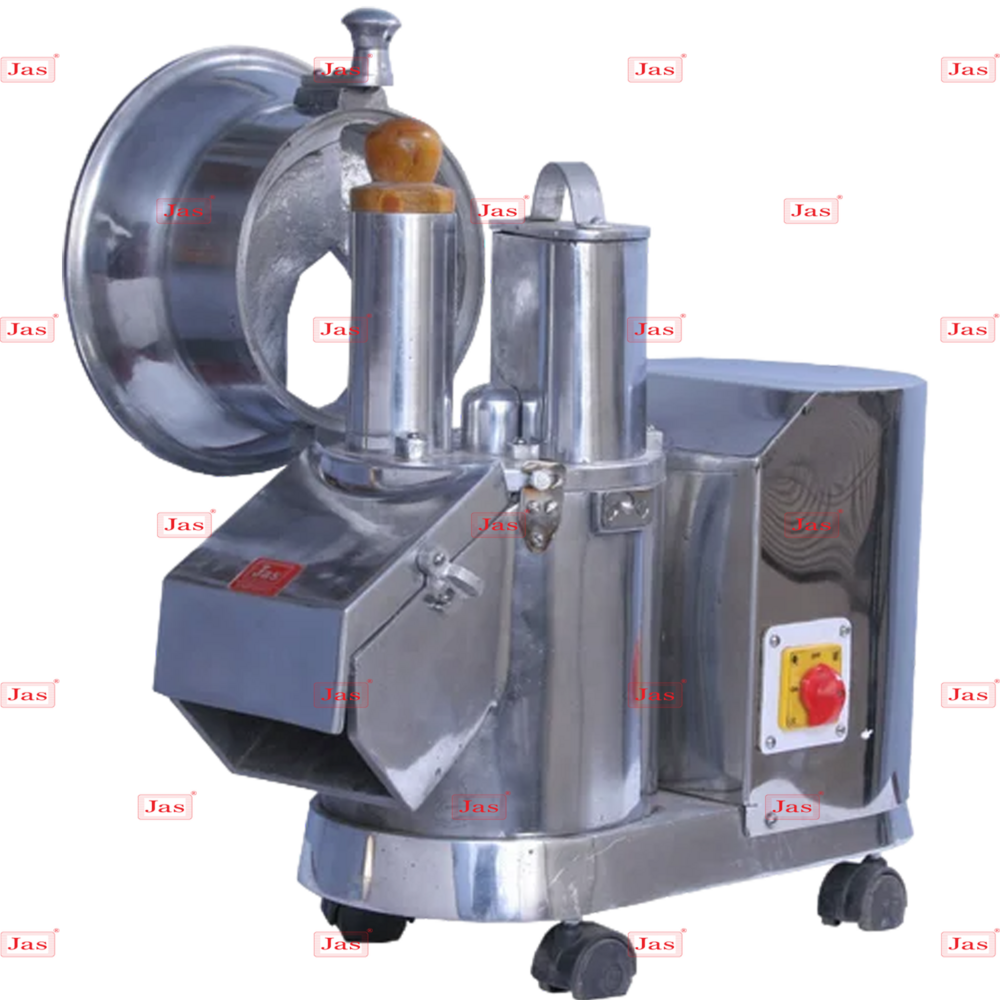

Chikki Making Machines

Price 67500 INR/ Piece

Chikki Making Machines Specification

- Frequency

- 50-60 Hertz (HZ)

- Phase

- Single Phase

- Automation Grade

- Semi Automatic

- Voltage

- 220 Volt (v)

- Power

- 0.5-1 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Chikki Making Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Chikki Making Machines

A Chikki Making Machine is a specialized food processing unit designed to automate the production of traditional Indian brittle snacks like groundnut chikki, sesame chikki, and mixed nut bars. The machine typically performs multiple functions such as mixing jaggery syrup with ingredients, spreading the hot mixture, rolling it to uniform thickness, and cutting it into precise rectangular or square pieces.

Made from food-grade stainless steel, the machine ensures hygiene, consistency, and efficiency. Depending on the model, it may be semi-automatic or fully automatic, and is ideal for small to medium-scale food businesses aiming for mass production with minimal manual labor.

Efficient Chikki Production for Modern Enterprises

This semi-automatic Chikki making machine streamlines the production of traditional sweets while reducing manual effort. Its compact and eco-friendly structure, paired with low energy consumption and quiet operation, creates a productive and sustainable work environment. The high efficiency of the machine supports businesses dealing in bulk production and distribution, making it well-suited for Indias dynamic marketplace.

Reliable and Versatile for All Business Types

With simple installation using a standard 220V single-phase supply, our Chikki making machine is compatible with a variety of commercial settings. Whether you are a wholesaler, retailer, or manufacturer, this machines robust design and user-friendly operation ensure you can meet increased demand with confidence and minimal environmental impact.

FAQs of Chikki Making Machines:

Q: How does the semi-automatic Chikki making machine work?

A: The semi-automatic Chikki making machine combines automated components with manual inputs, allowing for efficient mixing, shaping, and cutting of Chikki. Operators simply load ingredients, initiate the process, and monitor the machine, ensuring quality output with reduced physical labor.Q: What are the benefits of using this Chikki making machine?

A: The main benefits include lower energy consumption, reduced noise, eco-friendly operation, and a compact structure. These features lead to cost savings, easier installation, and a sustainable production processall while delivering high efficiency.Q: When is the machine most suitable for use?

A: This machine is ideal for small- to medium-scale Chikki producers who need consistent quality and output. It is especially valuable when demand surges, or where labor savings and energy efficiency are critical to business success.Q: Where can this machine be installed and used?

A: The Chikki making machine can be installed in commercial kitchens, small factories, retail production facilities, or any standard space with a 220-volt single-phase electrical outlet. Its compact design allows flexibility in placement.Q: What process does the machine follow to produce Chikki?

A: The machine automates key steps such as mixing, forming, and cutting Chikki. Users add the ingredients, set parameters, then the machine handles the rest, ensuring a uniform, high-quality product with less manual intervention.Q: How can distributors, exporters, and retailers in India benefit from this machine?

A: These businesses benefit by increasing their production capacity while minimizing operational costs. The machines energy efficiency and low noise support compliance with environmental standards, making it an attractive option for the Indian market.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Industrial Gas Oven

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 418 pizzas at a time Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Automatic Coconut Flakes Machine

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 230/440 Volt (v)

Automatic : No

Capacity : 1001000 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Sieving Machine

Price 49500 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : No

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Papaya Peeling Machine

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Capacity : 10 Kilograms per batch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free