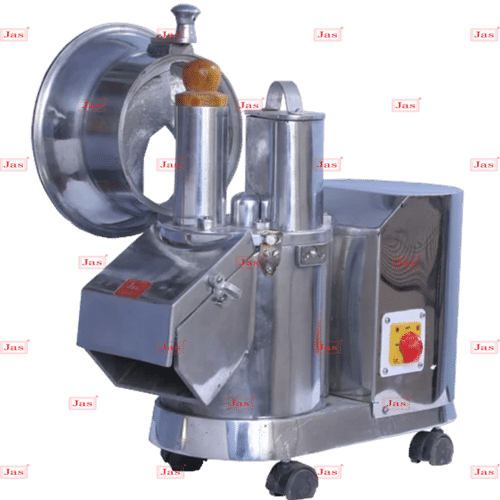

Coconut Chips Making Machine

Price 12000 INR/ Unit

Coconut Chips Making Machine Specification

- Automation Grade

- Automatic

- Power Source

- Electric

- General Use

- Industrial

- Material

- Stainless Steel

- Capacity

- 10-1000 Kg/hr

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Stand

- Voltage

- 230/440 Volt (v)

- Color

- Sliver

- Warranty

- 1 Year

Coconut Chips Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Coconut Chips Making Machine

-

Dehusking: Removing the outer husk of the coconut to expose the shell.

-

Deshelling: Breaking open the coconut shell to extract the coconut meat.

-

Slicing/Cutting: Slicing or cutting the coconut meat into thin strips or chips.

-

Drying: Drying the coconut chips to reduce moisture content and preserve shelf life.

-

Packaging: Optionally, some machines may also include packaging capabilities or integrate with packaging lines.

Features to Consider in a Coconut Chips Making Machine:

-

Capacity: Machines can range from small-scale units suitable for home use or small businesses to large industrial units for commercial production.

-

Automation: Degree of automation varies; some machines may be manual or semi-automatic, while others are fully automated.

-

Material Quality: Quality of materials used in construction affects durability and hygiene standards.

-

Processing Speed: Efficiency and speed of processing coconuts into chips.

-

Energy Efficiency: Operating costs and energy consumption.

Types of Machines:

-

Manual Machines: Simple machines operated by hand, suitable for small-scale production.

-

Semi-Automatic Machines: Require some manual intervention but automate certain processes like slicing or drying.

-

Fully Automatic Machines: Operate without manual intervention once set up, suitable for high-volume production.

Sophisticated Automation for Consistent Output

Equipped with a PLC control system, the machine ensures precision in coconut chip production. The automated process minimizes human intervention, resulting in consistent chip size and quality ideal for large-scale operations, and simplifying control with an intuitive interface.

Durability and Hygiene in Design

Constructed entirely from stainless steel, this coconut chips maker meets the highest standards for industrial food processing. Stainless steel not only guarantees longevity but also ensures the surface remains hygienic and easy to clean, reducing contamination risks.

FAQs of Coconut Chips Making Machine:

Q: How does the Coconut Chips Making Machine streamline the production process?

A: The machine automates key tasks such as slicing, drying, and packaging coconut chips using a PLC control system, significantly reducing manual labor while enhancing speed and product consistency.Q: What are the steps involved in using the Coconut Chips Making Machine?

A: Start by powering the machine with the designated electric source. Load the coconuts, set desired capacity and program chips dimensions via the PLC control. The machine will automatically process the coconuts into chips, ready for further drying and packaging.Q: When is the ideal time to maintain or service the machine?

A: Routine maintenance is recommended every three months, or as specified in the user manual provided. This helps ensure optimal performance and longevity, especially when operating continuously in industrial settings.Q: Where can this machine be installed in a production facility?

A: Thanks to its free-standing design, the machine can be installed in any suitable space within processing plants, minimizing the need for complicated setup and allowing flexibility in placement.Q: What benefits does the automatic operation offer over manual coconut chip production?

A: Automation provides consistent chip quality, reduces labor costs, increases hourly output, and lowers error rates. It also enhances food safety due to its hygienic stainless steel construction and controlled operation.Q: How can businesses in India acquire this Coconut Chips Making Machine?

A: The machine is available through several channels, including distributors, manufacturers, exporters, and wholesalers across India. Businesses can obtain it based on their scale and specific requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Fruit Processing Machines Category

Peanut Roaster

Minimum Order Quantity : 1 Unit

Voltage : 110415 Volt (v)

Capacity : 25 1000 Kg/hr

Automatic : Yes

Power : 0.25 to 5 Horsepower (HP)

Dry Fruit Chips Machine

Price 4000.00-300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110415 Volt (v)

Capacity : 30 Kg/hr

Automatic : Yes

Power : 1 Horsepower (HP)

Badam And Pista Cutting Machine

Price 38000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230 Volt (v)

Capacity : 1255 Kg/hr

Automatic : No

Power : 0.51 Horsepower (HP)

Dried Fruit Powder Making Machine

Price 29000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220 Volt (v)

Capacity : 150200 Kg/hr

Automatic : Yes

Power : 1500 Watt (w)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free