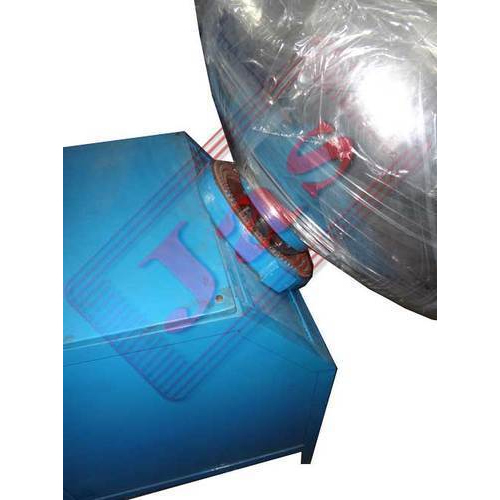

Commercial Spice Grinder Machine

Commercial Spice Grinder Machine Specification

- Material

- Stainless Steel

- Capacity

- 20 to 2000 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 110-440 Volt (v)

- Power

- 2 to 100 Horsepower (HP)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency, Compact Structure

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Commercial Spice Grinder Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Australia, North America, Middle East, Central America, Eastern Europe, South America, Asia, Africa

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, , Nagaland, South India, West India, Assam, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Delhi, Gujarat, Karnataka, North India, East India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Commercial Spice Grinder Machine

Commercial Spice Grinder Machine

Being well-equipped with the latest technology machinery & equipment and supported by a team of professionals, we are engaged in manufacturing and supplying Commercial Spice Grinder Machine. This machine is manufactured under the firm guidance of expert supervisors using high quality materials. To provide a defect free range, we check this machine on construction and performance parameters. Clients can obtain this Vermicelli Making Machine in different designs and finishing from us. Made in India Product

High-Capacity, Automated Spice Grinding

The Commercial Spice Grinder Machine delivers continuous, reliable performance, catering to substantial daily demands. Its automatic mechanism, governed by a PLC control system, ensures precise results with every batch. Built from durable stainless steel, it is designed for heavy-duty applications in industrial and commercial settings, efficiently grinding a wide array of spices.

Versatile Installation and Operation

Compatible with voltages ranging from 110 to 440 Volt, and boasting an adjustable horsepower between 2 and 100, this grinder easily adapts to various processing needs. Its user-friendly computerized interface streamlines setup, operation, and monitoringminimizing training time for staff and maintaining high safety standards.

Efficiency Meets Eco-Friendliness

Engineered for sustainability, the machine consumes less energy while delivering high grinding efficiency. The compact structure and low noise production contribute to a safer, more pleasant work environment. Its advanced technology supports cost-effective operations, yielding quality ground spices with minimal resource wastage.

FAQs of Commercial Spice Grinder Machine:

Q: How does the Commercial Spice Grinder Machine enhance spice processing operations?

A: The machine automates and streamlines spice grinding through its PLC control system, enabling precise, efficient, and consistent results. Its high grinding capacity (20 to 2000 kg/hr) and robust power (up to 100 HP) support large-scale production, significantly reducing manual labor and downtime.Q: What materials is the spice grinder made from, and why?

A: This grinder is constructed from high-grade stainless steel, ensuring durability, easy cleaning, and resistance to corrosion. Stainless steel is preferred in food processing to maintain hygiene standards and preserve the integrity of the spices during grinding.Q: Where can the grinder be installed, and what are its voltage requirements?

A: The grinder is suitable for installation in commercial kitchens, spice processing plants, and food manufacturing units across India. Its wide voltage compatibility (110440V) enables flexible deployment in various industrial and commercial settings.Q: What is the process for operating and maintaining the machine?

A: Operation is straightforward due to the computerized PLC control system. Regular maintenance involves periodic cleaning of components and routine checks for wear. The machines design facilitates easy access for maintenance, minimizing downtime and supporting consistent operation.Q: What benefits does the PLC Control System provide?

A: The PLC Control System ensures precise and automated grinding operations, reducing the chances of human error and maintaining consistent product quality. It also allows for easy programming and process monitoring, boosting productivity and operational safety.Q: When is warranty service available, and what does it cover?

A: The machine comes with a one-year warranty against manufacturing defects, valid at the installation site. The warranty covers repairs or replacement of defective parts resulting from original workmanship issues, offering peace of mind to users.Q: How is this grinder eco-friendly, and what efficiency features does it offer?

A: This grinder is designed for lower energy consumption and minimal noise output. The compact structure further reduces environmental impact, while its high grinding efficiency maximizes spice output with less resource use, benefiting both the environment and operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spice Processing Machine Category

Spice Grinding Machine

Price 1200.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : Yes

Warranty : 1 Year

Control System : PLC Control

Hammer Mill Pulverizer

Price 10000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : Yes

Warranty : 1 Year Against Manufacturing Defect At Our Site

Control System : PLC Control

Chilli Cleaning Machine

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Automatic : Yes

Warranty : 1 Year Against Manufacturing Defect At Our Site

Control System : PLC Control

Spice Roaster Machine

Price 65000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Automatic : No

Warranty : 1 Year Against Manufacturing Defect At Our Site

Control System : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free