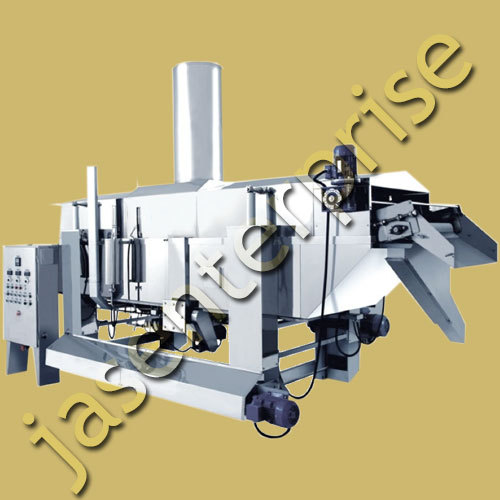

continuous namkeen fryer

Price 50000 INR/ Unit

MOQ : 1 Unit

continuous namkeen fryer Specification

- Machine Type

- Automatic Fryer

- Function Type

- Frying

- Heating Method

- Thermic Fluid / Diesel / Gas / Electric

- Speed Mode

- Variable

- Noise Level

- Low

- Feeding System

- Continuous Conveyor

- Features

- Consistent Frying, Oil Recycling, Easy Cleaning

- Operating Temperature

- 120C 180C

- Power Source

- Electric

- Automation Grade

- Automatic

- Phase

- Three Phase

- Frequency

- 50 Hz

- Product Type

- Continuous Namkeen Fryer

- General Use

- For Frying Namkeen Snacks

- Material

- Stainless Steel

- Type

- Continuous Fryer

- Capacity

- 325 -350 Kg/hr

- Weight (kg)

- 1200-1500

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Controlled

- Installation Type

- Free Standing

- Voltage

- 415 Volt (v)

- Power

- 750-1500 Watt (w)

- Dimension (L*W*H)

- Customized (Typical: 3800x1200x1550 mm)

- Raw Material

- Stainless Steel

- Feature

- Energy Efficient, Corrosion Resistant, Low Maintenance

- Color

- Silver

continuous namkeen fryer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

About continuous namkeen fryer

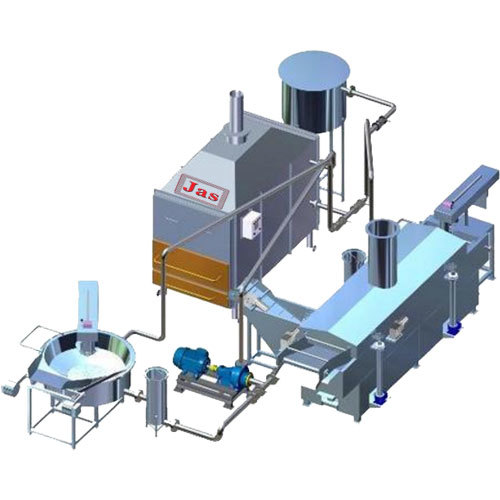

Owing to our vast knowledge in this domain, we are able to manufacture and export best quality continuous Namkeen fryer. Our well-trained professionals manufacture these fryers in our well-equipped infrastructure facility by making use of modern tools and machines. We manufacture these fryers keeping in mind the industry laid parameters, therefore using top quality stainless steel and other components. Owing to its high performance and longer service life, the continuous Namkeen fryer is highly appreciated by our patrons.Advance Features of Continuous fryer with heat exchanger

- Complete system consists of frying section with paddles and sub merger belt, top hood, takeout belt, continuous oil filter, day oil tank and heat exchanger.

- Make up oil is continuously added to the fryer to maintain optimum level.

- The flow of oil ensures a linear flow of oil, which is necessary in order to have a uniform frying time for all the slices.

- The equipment is designed to have a low oil holding capacity (325 -350 liter) in order to achieve low oil turnover ratio.

- Speed of both the belts can be varied by a variable frequency drive to adjust the frying time. Similarly flow of inlet oil can be regulated with valves.

- The continuous oil filtration is carried out by a belt type filter, which keeps the frying oil clean and filtered particles are collected in a tray.

- A stainless steel 304 made oil tank is placed with the fryer which can accommodate entire oil in the system.

- After frying the Namkeen, farsan are received by takeout belt.

Tailored for Industrial Scale Namkeen Frying

With a robust stainless steel build and advanced automation, this fryer manages large batches of namkeen snacks efficiently. The food-grade SS mesh conveyor operates continuously, ensuring consistent throughput and uniform frying results every time. Its PLC-based control system and digital temperature display allow precise adjustments, making it ideal for manufacturers demanding productivity and reliability.

Comprehensive Safety and Energy Features

Engineered with multiple safety mechanisms such as overheat protection, emergency stop switches, and an energy-efficient operating design, this fryer provides secure and reliable performance. These features, along with optimized fuel consumption options (thermic fluid, diesel, gas, or electric heating), reduce operational risks and running costs, making it a sustainable investment for snack production facilities.

Effortless Cleaning and Maintenance

The integrated CIP (Clean-In-Place) system simplifies the cleaning process, eliminating downtime and manual labor associated with hygiene maintenance. Corrosion-resistant materials and a low-maintenance design extend equipment lifespan, ensuring minimal interruptions and a consistently hygienic production environment.

FAQs of continuous namkeen fryer:

Q: How does the continuous namkeen fryer ensure uniform frying and low oil retention?

A: The fryer uses a food-grade stainless steel mesh conveyor for continuous feeding, regulated heat, and systematic oil circulation via a pump and filter unit. These combined with digital temperature control guarantee even heat distribution and minimize oil absorption, resulting in uniformly fried, crisp namkeen with low oil retention.Q: What safety features are included in the fryer and how do they protect operators?

A: This fryer is equipped with overheat protection sensors and an emergency stop switch, automatically preventing dangerous temperature spikes and allowing immediate halting of operations in case of emergencies. These features prioritize operator safety and help avoid accidents during commercial use.Q: Where can this fryer be installed, and does the manufacturer offer installation support?

A: Designed as a free-standing unit, the fryer can be installed in commercial snack production facilities. The manufacturer provides dedicated installation support to ensure seamless setup and integration into existing production lines.Q: What is the process for cleaning this fryer after use?

A: The machine features an automatic CIP (Clean-In-Place) system, which allows internal cleaning without disassembly. This system circulates cleaning agents and water throughout the internal components, significantly reducing manual cleaning efforts and ensuring food-safe hygiene standards.Q: How does the fryer benefit my commercial snack production process?

A: Utilizing this fryer means higher production capacity (up to 350 kg/hr), consistent snack quality, reduced oil consumption, and energy-efficient operation. The automatic discharge and conveyor system enhance productivity while digital controls and variable speed modes provide flexibility tailored to your recipes.Q: When is it ideal to use this fryer for namkeen production?

A: This fryer is best suited for large-scale, continuous snack production operations where high output, uniform frying quality, and efficient oil use are priorities. Its robust construction and automation cater to the demands of busy manufacturing facilities.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Namkeen Making Machine Category

Potato Chips Frying Equipment

Price 350000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Computerized : Yes

Power : 6.515 Horsepower (HP)

Hydro Extractors

Price Range 28000.00 - 120000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Computerized : No

Power : 0.5 to 3 Horsepower (HP)

Nylon Sev Making Machines ( Wheat Sev Making Machine)

Price Range 60000.00 - 180000.00 INR / Unit

Minimum Order Quantity : 1 Ohm

Automatic : No

Computerized : No

Power : 1 to 3 Horsepower (HP)

Automatic Namkeen Packing Machine

Price 60000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS