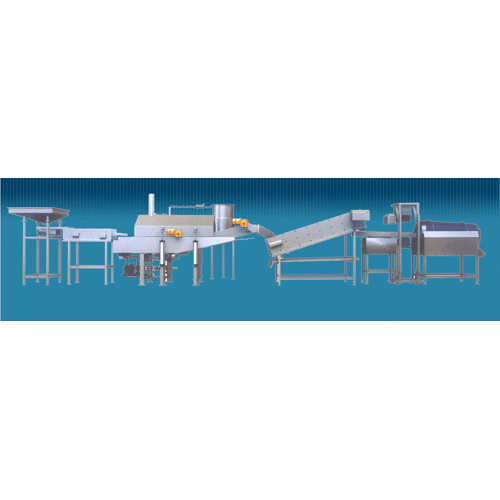

Continuous Snacks Making Line

Continuous Snacks Making Line Specification

- Material

- Stainless Steel

- Capacity

- 60 TO 550 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 110-440 Volt (v)

- Power

- 6.5 to 15 Horsepower (HP)

- Feature

- Lower Energy Consumption, ECO Friendly, High Efficiency, Low Noice, Compact Structure

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Continuous Snacks Making Line Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Manipur, Meghalaya, Andaman and Nicobar Islands, Uttarakhand, Lakshadweep, , South India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Delhi, Gujarat, Telangana, Central India, Chhattisgarh, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Continuous Snacks Making Line

Continuous Snacks Making Line

Pioneers in the industry, we offer Kurkure, Cheese Corn Ball Pellets, gold finger/ fryums Batch Type Fryer such as s they are developed from high quality steel using sophisticated technology. These snack fryer machines have become an indispensable items for snack industries throughout the world, for their exclusive nature and more durability. Easy to use these machines are completely resistant to corrosion and last for a long time. We offer these machines at industry leading prices.

All the Lines have following features...

- Low edible oil take up

- Low fuel Consumption.

- Improved productivity with excellent product quality.

- Very low labour requirement.

- Excellent online oil filtration.

- High oil turnover ratio

- Indirect Heating Arrangement.

Advanced Computerized Control

The system utilizes a sophisticated PLC control for precise automation, optimizing production parameters in real-time. This ensures the snacks are consistently produced to the desired quality standards, minimizing human error and maximizing throughput.

Eco-Friendly and Efficient Design

Engineered with sustainability in mind, the snacks making line features lower energy consumption alongside high efficiency. The use of stainless steel and noise reduction technology enhance both environmental and workplace conditions, aligning with modern manufacturing standards.

FAQs of Continuous Snacks Making Line:

Q: How does the PLC control system benefit the snacks making process?

A: The integrated PLC control system automates key manufacturing steps, allowing for precise monitoring and adjustment of variables. This results in consistent product quality, reduced waste, and improved operational efficiency.Q: What types of snacks can be produced using this continuous making line?

A: This equipment is suitable for a wide range of snacks, including chips, puffs, and other extruded products. Its flexible design allows manufacturers to customize production based on the ingredients and snack varieties required.Q: When is it advisable to utilize this snacks making line in your production facility?

A: Implementing this snacks making line is ideal when you require high-capacity outputbetween 60 and 550 kg/hrcoupled with energy-efficient and eco-friendly manufacturing. Its especially beneficial for expanding operations or upgrading existing equipment.Q: Where can this machine be installed within your manufacturing setup?

A: Thanks to its compact structure, the snacks making line can be installed in diverse manufacturing settings, from large-scale factories to smaller production units. The flexible voltage range allows for reliable operation throughout India.Q: What are the main benefits of using a continuous snacks making line with automatic features?

A: Automatic operation enhances productivity while lowering labor involvement, noise levels, and energy usage. It streamlines workflow, improves workplace safety, and ensures uniform snack quality throughout production.Q: How does the warranty support provide reassurance for buyers and operators?

A: A one-year warranty against manufacturing defects at your site is included, ensuring that any technical issues related to the build are addressed promptly. This minimizes downtime and supports continuous production cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Snacks Making Machine Category

Banana Chips Frying Equipment

Price Range 350000.00 - 700000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

Voltage : 110440 Volt (v)

Warranty : 1 Year Against Manufacturing Defect At Our Site

Snack Pellet Frying Line

Price Range 500000.00 - 2200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Lower Energy Consumption, ECO Friendly, Low Noice, High Efficiency, Compact Structure

Voltage : 110440 Volt (v)

Warranty : 1 Year Against Manufacturing Defect At Our Site

Industrial Popcorn Making Line

Price 600000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 415 Volt (v)

Warranty : 1 Year warranty against manufacturing defect.

Automatic French Fries Making Machine

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230 Volt (v)

Warranty : One year against manufacturing defect at our side

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free