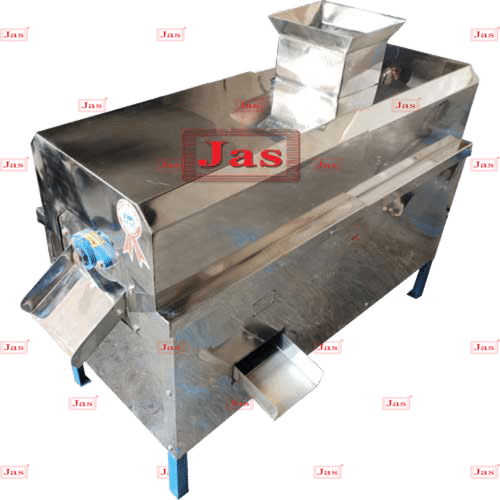

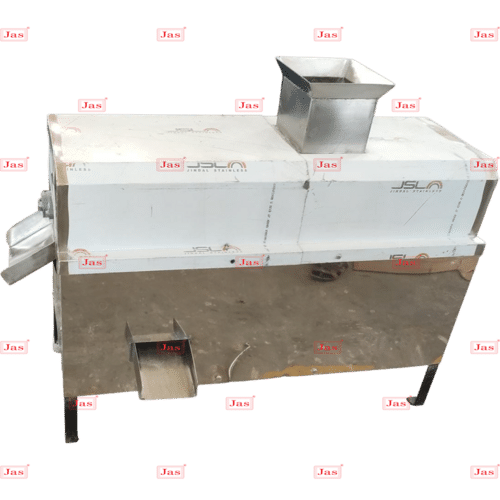

Custard Apple Pulper Machine

Price 32500 INR/ Unit

Custard Apple Pulper Machine Specification

- Type

- Pulper Machine

- Material

- Stainless Steel

- Capacity

- 100-500 Kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Voltage

- 230-440 Volt (v)

- Frequency (MHz)

- 50-60 Hertz (HZ)

- Cutting Thickness

- Adjustable

- Size

- Standard

- Width

- Customizable

- Weight

- Approx 150 Kg

- Dimension (L*W*H)

- 1200 x 600 x 1100 mm

- Material Contact Parts

- Food Grade Stainless Steel

- Safety Features

- Overload Protection

- Noise Level

- Low

- Cleaning

- Easy to Clean and Maintain

- Separation Mechanism

- Efficient Separation of Seeds and Pulp

- Finishing

- Polished

- Discharge System

- Direct Output and Seed Ejection

- Suitable Fruit

- Custard Apple, Sapota, Mango, etc.

- Frame Construction

- Heavy Duty Mild Steel with SS Cladding

- Motor Power

- 2 HP

- Application

- Industrial, Commercial Food Processing Units

Custard Apple Pulper Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Custard Apple Pulper Machine

- Feeding The custard apples are fed into the machine either manually or via a conveyor system

- Pulper Mechanism The machine uses a combination of blades and screens or mesh to separate the pulp from the seeds and rind Some machines have a rotating drum or auger that crushes and presses the fruit

- Pulp Extraction The pulp is collected in a container or tank while the seeds and other waste are expelled separately

- Cleaning After use the machine needs to be cleaned to prevent contamination and maintain hygiene Many models have removable parts for easier cleaning

- Key Features to Consider

- Capacity Determine how much fruit you need to process Machines come in various sizes from small units for home use to large industrial models

- Material Look for durable materials like stainless steel which are easier to clean and resistant to corrosion

- Ease of Use Consider how easy the machine is to operate and whether it requires manual labor or is fully automated

- Cleaning Check if the machine is easy to disassemble and clean

- Power Depending on the size and capacity the machine might require a certain amount of power Ensure you have the necessary electrical setup

- Cost Prices can vary widely based on the machines features and capacity Balance your budget with your needs

Robust Construction and High Performance

Designed with a heavy-duty mild steel frame and stainless steel cladding, this pulper machine is tough and built to last. Its efficient 2 HP motor ensures high productivity, processing up to 500 kg of fruit per hour. Ideal for use in food processing units, its polished finish enhances hygiene and aesthetics.

Advanced Separation and Discharge Mechanism

A reliable separation mechanism effectively divides seeds from pulp, ensuring minimal waste and high-quality output. Direct discharge of pulp and automatic ejection of seeds streamline the workflow, making this machine suitable for continuous operations.

User-Friendly and Safe Operation

With overload protection and low noise levels, this pulper machine prioritizes safety and comfort. All contact parts are crafted from food-grade stainless steel for hygiene. The equipment is designed for effortless cleaning and maintenance, helping to reduce downtime and operational hassles.

FAQs of Custard Apple Pulper Machine:

Q: How does the seed and pulp separation process work in this pulper machine?

A: The machine utilizes an advanced internal mechanism that efficiently separates seeds from the pulp as the fruit is processed. Seeds are automatically ejected through a dedicated outlet, while the extracted pulp is discharged directly for collection or further processing.Q: What types of fruits can be processed with this pulper machine?

A: This machine is suitable for custard apple, sapota, mango, and various other soft-fleshed fruits. Its robust design and adjustable cutting thickness allow it to handle a range of fruit sizes and textures.Q: When is the Custard Apple Pulper Machine typically used in food processing units?

A: The machine is generally employed during the initial stage of fruit processing, where bulk quantities of fruits need to be pulped efficiently in industrial and commercial kitchens, juice plants, and food manufacturing units.Q: Where can the machine be installed, and does it require special infrastructure?

A: The machine can be installed in standard food processing facilities with access to 230-440V power supply. It has a compact, customizable design suitable for various workspace layouts and does not require specialized flooring or heavy foundations.Q: What are the key benefits of using this pulper machine for commercial processing?

A: Key benefits include a hygienic, high-capacity operation, efficient seed-pulp separation, low noise levels, easy-to-clean surfaces, and enhanced safety through overload protection. These features collectively boost productivity and ensure product consistency.Q: Is the machine fully automatic and easy to maintain?

A: Yes, the machine operates automatically, requiring minimal supervision. Its stainless steel contact parts are easy to detach and clean, minimizing downtime and facilitating maintenance for continuous operation.Q: Can the cutting thickness be adjusted for different types of fruits?

A: Absolutely. The machine allows users to adjust the cutting thickness, ensuring optimal extraction and quality for a variety of fruit types and processing requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fruit Pulping Machine Category

Sitafal Pulp Making Machine

Price Range 36000.00 - 360000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Voltage : 110 440 Volt (v)

Warranty : One year against manufacturing defects at our site, except all wear and tear parts

Imli Pulp Machine

Price Range 36000.00 - 360000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Voltage : 110 440 Volt (v)

Warranty : One year against manufacturing defects at our site, except all wear and tear parts

Mango Pulp Making Machine

Price Range 36000.00 - 360000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Voltage : 110 440 Volt (v)

Warranty : One year against manufacturing defects at our site, except all wear and tear parts

Mango Pulp Machine

Price 2998.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Voltage : 230440 Volt (v)

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free