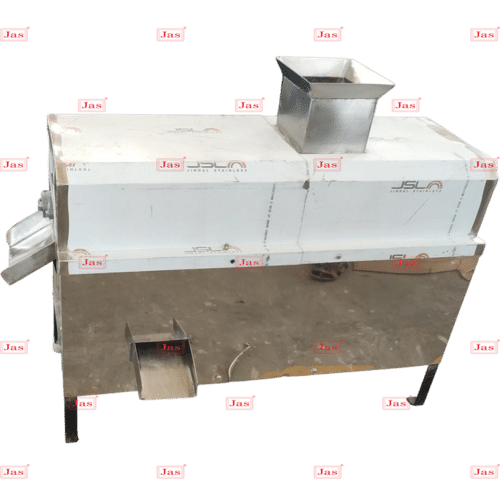

Cutter Mixer Machine

Price 8000 INR/ Unit

Cutter Mixer Machine Specification

- Capacity

- 2.5-20 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Cutter Mixer Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Cutter Mixer Machine

- Blades and Cutters: Equipped with sharp blades or cutting elements that can chop, slice, or dice ingredients.

- Mixing Bowl: Typically has a large bowl or container where ingredients are placed for mixing.

- Motor: Powered by a motor that drives the blades and agitates the mixture.

- Speed Control: Many models offer adjustable speed settings to control the intensity of cutting and mixing.

- Safety Features: Includes safety guards and automatic shut-off mechanisms to ensure safe operation.

Uses:

- Food Industry: Often used to prepare ingredients for sauces, soups, or other food products. It helps in chopping vegetables, mixing meats, and blending various ingredients.

- Industrial Applications: Used in manufacturing processes that require precise cutting and mixing of raw materials.

- Laboratories: Employed for mixing and homogenizing samples in research and development settings.

Benefits:

- Efficiency: Speeds up the process of chopping and mixing compared to manual methods.

- Consistency: Provides uniform results in terms of texture and mixture quality.

- Versatility: Can handle a variety of ingredients and can often be used for multiple tasks beyond just mixing.

Efficient Operation for Multiple Applications

The Cutter Mixer Machine offers a seamless blend of speed and performance, suitable for food processing, industrial manufacturing, and laboratory use. Its automatic capabilities reduce manual effort, while its compact design enables easy integration into diverse workspaces. Whether you are a small business or a large-scale manufacturer, this machine delivers results you can rely on.

Eco-Friendly and Cost-Effective Design

Focusing on sustainability, this cutter mixer promises lower energy consumption and reduced noise pollution. Its high-efficiency engineering means less waste while ensuring consistent product quality. With its environmentally conscious build, businesses can reduce operational costs and support green initiatives without compromising on productivity.

FAQs of Cutter Mixer Machine:

Q: How does the Cutter Mixer Machine ensure high efficiency during operation?

A: The machine utilizes optimized blades and advanced motor technology to deliver rapid mixing and cutting, maintaining consistent speed and output. Its automatic features allow for streamlined processes, resulting in higher throughput and greater reliability compared to manual methods.Q: What is the recommended usage process for this automatic Cutter Mixer Machine?

A: To operate the machine, simply load the ingredients or materials into the mixing chamber, select the desired setting, and start the automatic cycle. The machine handles all mixing and cutting tasks, ensuring uniform results with each batch. Regular cleaning and maintenance ensure longevity and optimal function.Q: When is the ideal time to use the Cutter Mixer Machine in production?

A: This machine is best used whenever rapid and uniform mixing is requiredwhether during the preparation stage in food processing, ingredient blending in pharmaceutical production, or sample preparation for research labs. Its flexibility in capacity supports both small and large-scale operations.Q: Where can I purchase the Cutter Mixer Machine in India?

A: The cutter mixer machine is available through multiple channels in India, including distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers. This extensive network ensures accessibility for different business needs across the country.Q: What are the main benefits of using this eco-friendly Cutter Mixer Machine?

A: Key benefits include lower energy consumption, minimal noise output, high operational efficiency, and a compact structure. The eco-friendly design reduces overall costs and environmental impact, while the versatile capacity range meets various production demands.Q: How does the compact structure of the machine contribute to its usability?

A: The compact structure allows the machine to fit easily into small or crowded work environments, optimizing space utilization. It also simplifies installation and maintenance, making it a practical choice for businesses with limited operational areas.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Moringa Leaves Powder Processing Plant

Price 550000 INR / Piece

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : No

Capacity : 302500 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Tomato Crusher

Price 33000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Automatic : Yes

Capacity : 302600 Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Veg. Manchurian Making Machine

Price 45000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220 Volt (v)

Automatic : Yes

Capacity : 90 Pcs/min

Pasta Extruder Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Automatic : Yes

Capacity : 125 kg/Hr Kg/hr

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free