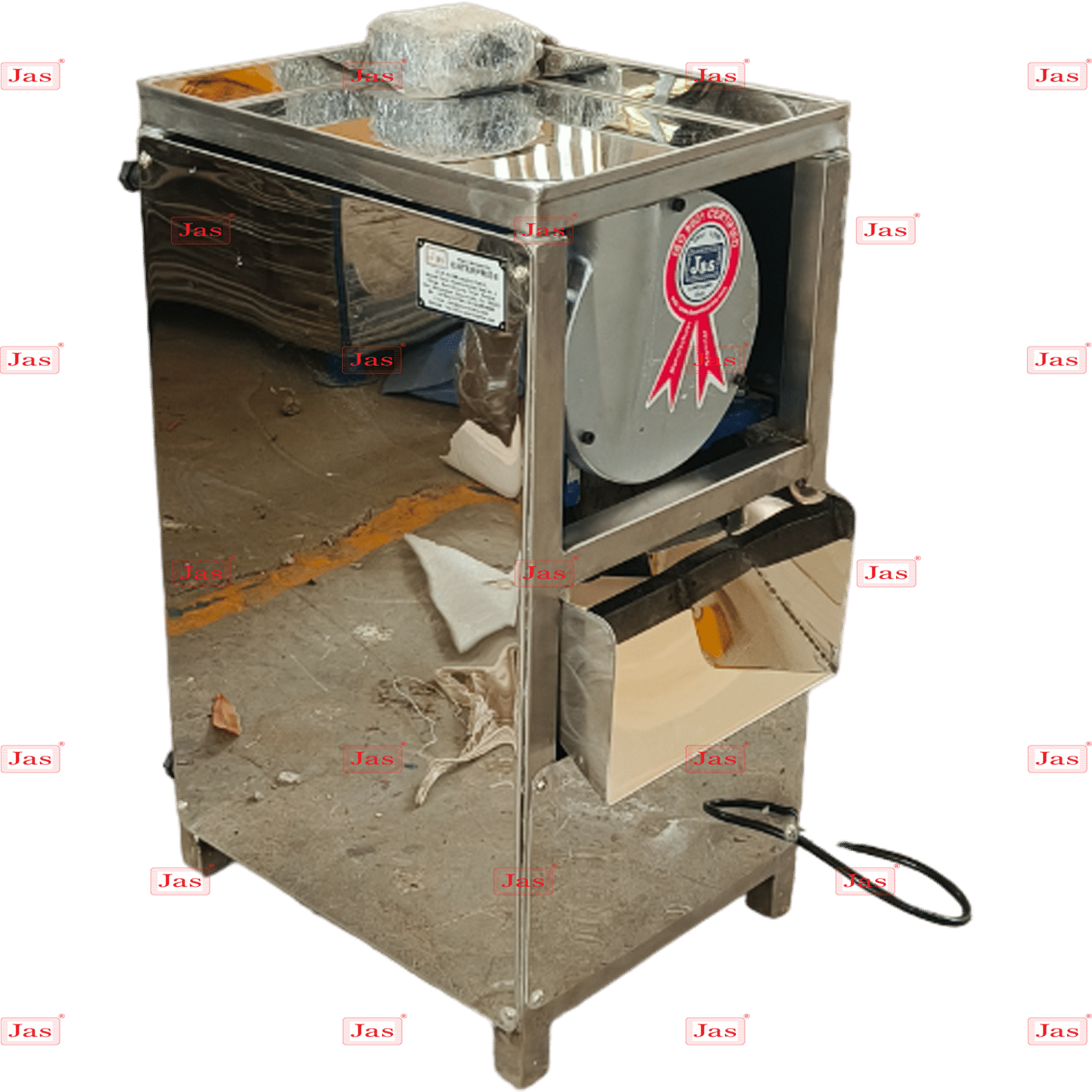

Dry Fruit Chips Making Machine

Price 18000 INR/ Unit

Dry Fruit Chips Making Machine Specification

- Capacity

- 12-55 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Dry Fruit Chips Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Dry Fruit Chips Making Machine

-

Feeder System This component is responsible for feeding raw fruits into the machine It often includes conveyors or hoppers to ensure a steady flow

Slicing Mechanism This part slices the fruit into thin uniform chips It can use sharp blades or cutting rollers to achieve the desired thickness

Drying Chamber After slicing the fruit chips are dried to remove moisture Drying methods can vary

Hot Air Drying Uses hot air to evaporate moisture

Freeze Drying Involves freezing the fruit and then removing the ice through sublimation

Dehydration Employs heat and airflow to dry the fruit

Cooling System Once dried the chips need to be cooled before packaging to prevent moisture absorption and ensure freshness

Packaging Unit Some machines come with an integrated packaging system to seal the chips in bags or containers

Control Panel Allows operators to set parameters like temperature drying time and slicing thickness

Innovative Design for Seamless Operation

This dry fruit chips making machine boasts an automatic control system and compact structure, making it suitable for both small and large-scale processing. Its ergonomic design minimizes space requirements and simplifies integration into existing workflows, ensuring efficient operation.

Eco-Friendly and Energy Efficient

With its ECO Friendly construction and lower energy consumption, the machine supports sustainable manufacturing practices. It delivers high output while minimizing your environmental footprint, making it ideal for businesses looking to balance productivity with responsibility.

FAQs of Dry Fruit Chips Making Machine:

Q: How does the Dry Fruit Chips Making Machine process dry fruits into chips?

A: The machine automates the slicing and processing of dry fruits, using sharp blades and precise mechanisms to ensure consistent chip sizes. After loading the raw dry fruits, the machine efficiently cuts them into uniform chips within minutes.Q: What voltage and capacity does the Dry Fruit Chips Making Machine operate at?

A: This machine operates on either 230 or 440 volts, giving flexibility for different facility requirements. It can process between 12 to 55 kilograms of dry fruit chips per hour, making it suitable for a range of production volumes.Q: When is it recommended to use this machine in your production line?

A: It is advisable to use this machine when you require high-volume, continuous, and uniform slicing of dry fruitswhether you run a small retail operation, a large manufacturing plant, or a packaging unit.Q: Where can I purchase the Dry Fruit Chips Making Machine in India?

A: You can acquire this machine from several authorized distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. Most notable food processing equipment marketplaces and industrial suppliers offer this product.Q: What is the process involved in operating the machine?

A: To operate, simply load the dry fruits into the feeding chamber, select the appropriate cutting mode, and start the fully automatic system. The machine will then slice the fruits and dispense uniform chips, requiring minimal human intervention.Q: How does using this machine benefit my business?

A: By adopting this machine, you gain from its high efficiency, reduced noise, lower energy bills, and eco-friendly operation. Its compact structure saves floor space, and automation reduces labor costs while increasing product consistency.Q: Is the Dry Fruit Chips Making Machine suitable for large-scale export operations?

A: Yes, its robust capacity, high efficiency, and low energy consumption make it ideal for exporters and bulk processors who require reliable, large-scale production with consistent quality results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry Fruit Processing Machines Category

Dry Dates seed removal machine

Price 80000.0 INR

Minimum Order Quantity : 1

Automatic : Other, Semiautomatic

Voltage : 220V to 380V

Material : Stainless Steel

Capacity : 70100 kg/hr

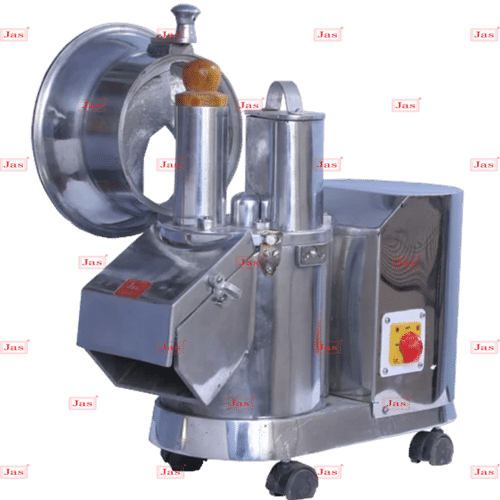

Coconut Chips Making Machine

Price 12000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Voltage : 230/440 Volt (v)

Material : Stainless Steel

Capacity : 101000 Kg/hr

Almond Cutter

Price 1300.00-30000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Voltage : 110415 Volt (v)

Material : Stainless Steel

Badam And Pista Cutting Machine

Price 38000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : No

Voltage : 230 Volt (v)

Material : Stainless Steel

Capacity : 1255 Kg/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS