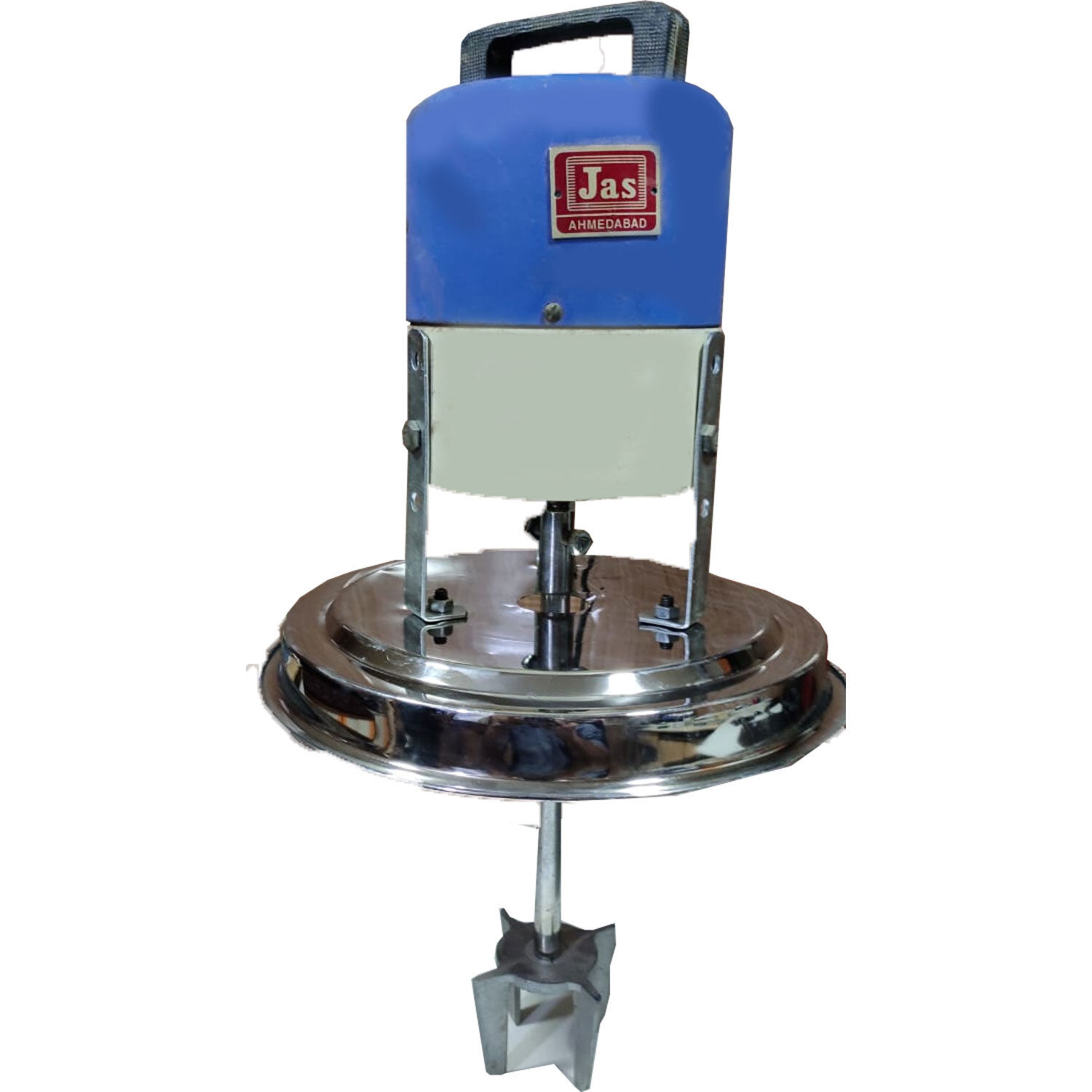

Electric Stirrer / liquid agitator

Price 12900 INR/ Unit

MOQ : 1 Unit

Electric Stirrer / liquid agitator Specification

- Application

- Liquid Mixing, Dairy, Food & Beverage, Pharmaceuticals

- Material Grade

- SS304

- Installation Type

- Tabletop / Floor Mounted

- Features

- Rust Proof, Easy to Clean, High Efficiency Mixing

- Processing Technology

- Precision Fabricated

- Power Source

- Electric

- Control System

- Manual Speed Control

- Material

- Stainless Steel

- Automatic Grade

- Semi Automatic

- Capacity

- 50 Water+ 50.Curd Kg/hr

- Power

- 0.25 HP

- Voltage

- 170 To 250 Volt (v)

- Temperature Range

- Ambient to 80C

- Shape

- Agitator Type

- Usage

- Agitating, Mixing of Liquids

- Size

- Medium

- Dimension (L*W*H)

- 400 mm x 300 mm x 700 mm

- Weight

- Approx. 18 kg

- Color

- Blue & Silver

Electric Stirrer / liquid agitator Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 1 Months

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, , All India, South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Uttar Pradesh, Karnataka, North India, Kerala, Central India, Odisha, Chhattisgarh

About Electric Stirrer / liquid agitator

With an aim to provide finest quality products, we are engaged in manufacturing and exporting sturdily built Electric Stirrer. This stirrer is widely used in various industries like food, pulp, paper and chemical. Our offered stirrer is made available in different sizes, specifications and models that clients can avail as per their needs. This stirrer is manufactured using high grade stainless steel and other components that are obtained from legitimate vendors. Clients can avail this Electric Stirrer at market leading prices.Various characteristics:

- High material strength

- Longer service life

- Rugged construction

- Easy operation

Other details:

We offer Commercial stirrer/liquid agitator which comes in various specifications:Efficient & Versatile Liquid Mixing

Engineered for optimized performance, this Electric Stirrer / Liquid Agitator offers rapid, uniform mixing for liquids of up to 5000 cP viscosity. Its manual speed control and 10 to 30-minute mixing time cater to various batch sizes and materials, making it ideal for dairy, food, and pharmaceuticals. The quiet operation, overload protection, and rust-proof construction ensure both safety and longevity.

Robust Stainless Steel Construction

Crafted from SS304 stainless steel and mirror polished for hygiene, this agitator resists rust and corrosion, supporting heavy-duty day-to-day use. The robust impeller and precision fabrication guarantee consistent mixing and easy cleaning, ensuring compliance with stringent sanitary requirements in sensitive industries.

FAQs of Electric Stirrer / liquid agitator:

Q: How does the Electric Stirrer achieve efficient mixing of liquids with varying viscosities?

A: The stirrer employs a high-speed impeller (1440 RPM) and robust SS304 stainless steel blades, enabling it to mix liquids with viscosities up to 5000 cP. Manual speed adjustments allow for optimal agitation based on the liquids characteristics, ensuring uniform results within 10 to 30 minutes.Q: What are the key safety features of this liquid agitator during operation?

A: The agitator features built-in overload protection to prevent damage during operation, and its low noise design ensures safer working conditions. The mirror polished, rust-proof stainless steel construction also minimizes contamination risks while making cleaning straightforward.Q: When and where can this Electric Stirrer be installed for optimal performance?

A: This agitator is suitable for both tabletop and floor mounting, fitting seamlessly in laboratories, dairy processing plants, food and beverage facilities, and pharmaceutical production areas. It can be installed during equipment upgrades or when expanding production capabilities to improve mixing efficiency.Q: What is the process for cleaning and maintaining the agitator?

A: Thanks to its mirror-polished SS304 construction, the agitator can be easily cleaned with standard sanitizing agents. Regular inspection for wear or build-up, along with routine cleaning after each use, will optimize performance and maintain hygienic standards.Q: How does manual speed control benefit the mixing process?

A: Manual speed control allows users to adjust the agitation intensity based on the liquids viscosity and desired mixing time. This flexibility ensures optimal mixing results for a wide range of materials, from dairy liquids to more viscous pharmaceutical solutions.Q: What benefits does the rust-proof SS304 material provide for end users?

A: SS304 stainless steel offers superior resistance to rust and corrosion, ensuring a long equipment lifespan and reliable hygiene. This makes the agitator ideal for sensitive industries where contamination must be minimized, reducing maintenance efforts over time.Q: Where can the Electric Stirrer be sourced within India?

A: The Electric Stirrer / Liquid Agitator is available through authorized distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India, providing broad access to quality support and after-sales service.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Commercial Kitchen Equipments Category

Food Steamer

Price Range 5000.00 - 20000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Other, Automatic

Material : Stainless Steel

Pani Puri Serving Machine

Price 20000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 6 Months against manufacturing defect at our site

Gravy Making Machine

Price 9000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Semi Automatic

Material : Stainless Steel

Bowl Chopper

Price Range 30000.00 - 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Semi Automatic

Material : Stainless Steel

Warranty : One year against manufacturing defects at our site, except all wear and tear parts.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS