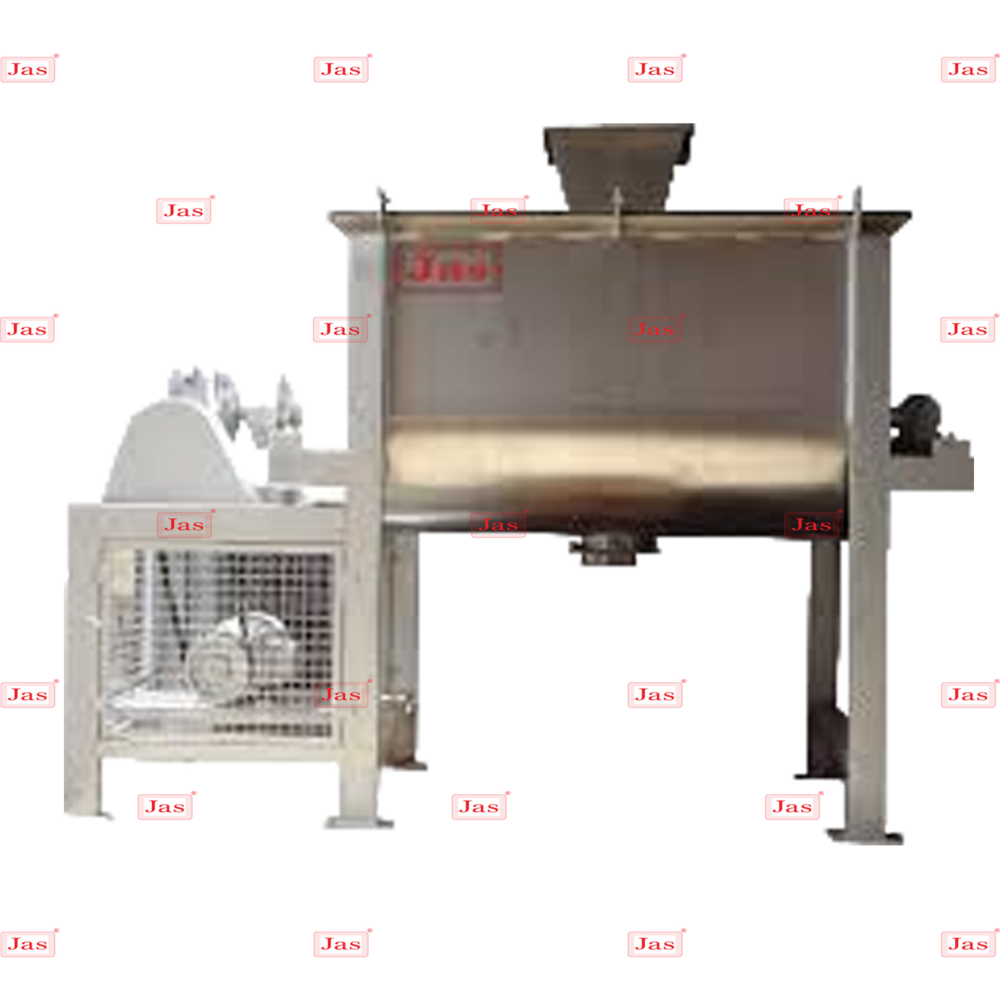

Flour Roasting Machine

Price 50000 INR/ Unit

Flour Roasting Machine Specification

- Capacity

- 5-500 Kg/hr

- Automatic

- Yes

- Voltage

- 230/440 Volt (v)

- Feature

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Flour Roasting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Western Union

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO

About Flour Roasting Machine

-

Heating Chamber: The part of the machine where the flour is exposed to heat. It may use electric, gas, or steam heating methods.

-

Stirring Mechanism: To ensure even roasting, the machine usually has a stirring or agitating system that constantly moves the flour.

-

Temperature Control: Allows precise control of the roasting temperature to achieve the desired level of roast.

-

Cooling System: After roasting, the flour needs to be cooled quickly to stop the cooking process and preserve its quality.

-

Conveyor System: In larger machines, a conveyor belt may be used to move the flour through different stages of roasting.

-

Ventilation: Proper ventilation is essential to manage the heat and any fumes produced during the roasting process.

Applications

- Baking: Roasted flour is used in recipes for bread, cookies, and cakes to enhance flavor.

- Soups and Sauces: It can be added to thicken and add a unique taste.

- Traditional Foods: In some cultures, roasted flour is used in traditional dishes and sweets.

Advanced Roasting Technology

Our Flour Roasting Machine incorporates state-of-the-art technology to ensure uniform roasting for a variety of applications. Its automated process significantly reduces manual intervention, enhances consistency, and improves output quality for your production lines.

Eco-Friendly and Efficient Operation

With a focus on sustainability, the ECO friendly design not only lowers energy consumption but also minimizes operational noise. This makes it suitable for businesses aiming to reduce their environmental impact while optimizing performance.

Versatile Design for Indian Industries

The compact structure and voltage flexibility allow seamless integration into both new and existing setups. Whether youre supplying small bakeries or large food processing units, this machine fits a variety of operational scales and requirements.

FAQs of Flour Roasting Machine:

Q: How does the flour roasting machine maintain high efficiency while being eco-friendly?

A: The machine utilizes advanced roasting mechanisms and insulation to reduce energy wastage and maintain optimal temperatures, which results in lower electricity consumption. Its high-efficiency design ensures maximum output with significantly reduced environmental impact.Q: What capacities are available for this flour roasting machine?

A: This machine is available in a wide range of capacities, processing anywhere from 5 kg/hr up to 500 kg/hr, making it suitable for both small batch and large-scale operations.Q: When should you choose a 230V or a 440V machine?

A: Selecting between 230V and 440V depends on your facilitys power supply specifications and production scale. The 230V option suits smaller operations or areas with lower voltage access, while 440V is ideal for industrial-scale production environments.Q: Where in India can this flour roasting machine be supplied or installed?

A: As a distributor, exporter, manufacturer, retailer, supplier, trader, and wholesaler, we offer nationwide delivery and installation services across India, ensuring accessibility in all major industrial and commercial regions.Q: What is the operational process for using this automatic flour roasting machine?

A: Operation is straightforward: set your desired parameters, load the flour, and let the automatic controls handle the roasting. The machines design guarantees uniform roasting with minimal supervision required.Q: What are the main benefits of using this compact flour roasting machine?

A: Users benefit from lower energy costs, reduced noise levels, and a space-saving footprint. Additionally, the machine delivers consistent roasting quality, supports eco-friendly manufacturing, and increases overall production efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Peanut Butter Making Machine

Price 85.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 501000 Kg/hr

Automatic : Yes

Warranty : 1 Year

Industrial Vibro Sifter

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 400 Kg/hr

Automatic : Yes

Warranty : One year against manufacturing defects at our site

Powder Mixing Machines

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 230/440 Volt (v)

Capacity : 101000 kg/betch Kg

Warranty : One year against manufacturing defect at our side

Chopping Machine

Price 9000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 to 440 Volt (v)

Capacity : 100 kgs Kg/hr

Automatic : Yes

Warranty : One year against manufacturing defects at our site

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS