Fully Automatic Corn Curls Kurkure Production Line

Fully Automatic Corn Curls Kurkure Production Line Specification

- Material

- Stainless Steel

- Capacity

- 100 TO 300 Kg/hr

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 440 Volt (v)

- Power

- 5 to 20 Horsepower (HP)

- Warranty

- 1 Year Against Manufacturing Defect At Our Site

Fully Automatic Corn Curls Kurkure Production Line Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 1000 Units Per Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Western Europe, Asia, Australia, South America, Eastern Europe, Middle East, Central America, North America, Africa

- Main Domestic Market

- Dadra and Nagar Haveli, Pondicherry, Uttarakhand, Maharashtra, , South India, Central India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Daman and Diu, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Madhya Pradesh, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Delhi, Gujarat, Uttar Pradesh, All India

- Certifications

- ISO 9001

About Fully Automatic Corn Curls Kurkure Production Line

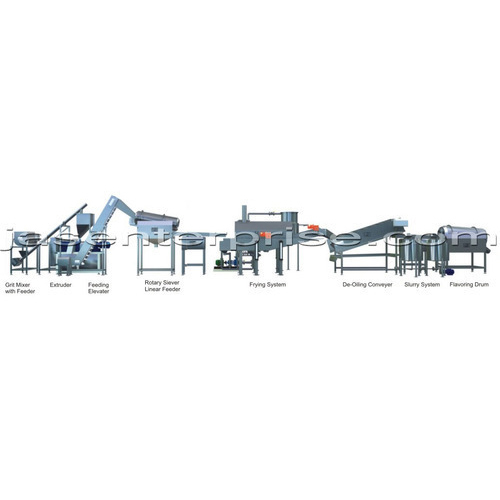

Fully Automatic Corn Curls Kurkure Production Line

Kurkure are extruded snacks, very crunchy and great in taste. Kurkure are made by extrusion process. The kurkure corn meal is moisturized in the flour mixer with water and fed to the rotary die extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the kurkure to improve their taste. Machines involved in making kurkure:

- Flour mixer with feeder- to mix corn meal with water to prepare the flour for kurkure and more mixture from mixer machine to rotary head extruder for kurkure type snacks.

- Rotary head extruder for kurkure type snacks- to cook the corn meal and extrude the kurkure from the die. The rotary die twists and curls the meal before extruding giving a uniform texture.

- Feeding elevator- this equipment is proved for transfer the corn curls from extruder to rotary sieve.

- Rotary sieve- the fines or small particles that are produced as the collets are removed by this rotary sieve.

- Continuous frying system with heat exchanger- to fry the kurkure in hot cooking oil. The uniform frying introduces the crunchy taste to the kurkure.

- De-oiling belt to remove exceed oil from corn curls.

- Linear feeder- this devices used to feed corn curls for flavoringon seasoning system.

- Automatic seasoning system with Slurry System -to add required seasoning to the fried and cooled kurkure to give the different flavorsto them

Advanced Automation & Quality Control

Fitted with a cutting-edge PLC control system, the production line ensures consistent product output with minimal manual oversight. Its computerized operation offers precise settings for ingredients and processing times, optimizing both quality and resource usage.

Robust Build & High Capacity

Manufactured from stainless steel, the production line withstands extensive industrial use and maintains food safety standards. With the ability to process 100 to 300 kg/hr, it is ideal for medium-to-large scale snack manufacturers and suppliers.

Comprehensive Service Coverage

A one-year warranty against manufacturing defects is provided, including service at your installation site. Distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India can benefit from reliable after-sales support.

FAQs of Fully Automatic Corn Curls Kurkure Production Line:

Q: How does the fully automatic Kurkure production line operate?

A: The production line utilizes a PLC-based computerized control system to automate mixing, extrusion, cutting, frying, and flavoring steps. Operators simply set process parameters, monitor via the control panel, and the system handles production with minimal supervision.Q: What materials are used in the construction of the production line?

A: This unit is fabricated from high-quality stainless steel, ensuring durability, hygiene, and compliance with food safety regulations during prolonged industrial operations.Q: When will installation and after-sales service be available?

A: Upon purchase, installation is scheduled as per your requirement, and the 1-year warranty against manufacturing defects is effective from the installation date, with service provided directly at your location.Q: Where can this production line be supplied or installed?

A: We supply and install this fully automatic Kurkure production line across India, serving distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers.Q: What is the production capacity of the Kurkure line, and can it be adjusted?

A: The system is designed for a production range of 100 to 300 kilograms per hour. Output can be fine-tuned through settings on the computerized control system to match specific production requirements.Q: How does using this production line benefit my business?

A: Automating Kurkure production enhances efficiency, reduces labor costs, minimizes inconsistencies, and ensures high-quality output, making it ideal for scaling your snack manufacturing operations.Q: What is the power and voltage requirement for operating the production line?

A: The production line requires a 440 Volt (v) electrical connection and operates within a power range of 5 to 20 Horsepower (HP), suitable for most industrial manufacturing environments in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

Table Top Grill

Price 6500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Computerized : No

Semi Automatic Chapati-Poori-Thepla Making Machine

Price 135000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : Lower Energy Consumption, ECO Friendly, Compact Structure, High Efficiency, Low Noice

Voltage : 110 to 440 Volt (v)

Computerized : No

Green And Leafy Vegetable Cutting Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : High Efficiency, Lower Energy Consumption, ECO Friendly, Low Noice, Compact Structure

Voltage : 110 to 440 Volt (v)

Computerized : No

Commercial Electric Pizza Oven

Price 7000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Feature : ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

Voltage : 230/440 Volt (v)

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS